Durable and Flexible Nylon Split Wire Loom for Effective Cable Management and Protection

Understanding Nylon Split Wire Loom A Comprehensive Guide

Nylon split wire loom is an essential component widely used in industries ranging from automotive to telecommunications. Its primary function is to protect and organize wires and cables, ensuring they are safeguarded from various external factors like abrasion, moisture, and chemicals. This article delves into the characteristics, applications, and advantages of nylon split wire loom, highlighting why it’s a favored choice for many applications.

What is Nylon Split Wire Loom?

Nylon split wire loom is a tubing system made from high-quality nylon, designed with a split along the length of the tubing. This split feature allows for easy insertion and removal of wires and cables, making it a user-friendly choice for both installation and maintenance. The tubing is highly flexible, allowing it to wrap around numerous cables while offering a snug fit that prevents movement.

The nylon material itself is known for its impressive resistance to wear and tear, while also providing good insulation properties. Nylon is not only resistant to abrasion but also to a variety of chemicals, making it ideal for use in environments where harsh conditions prevail.

Applications of Nylon Split Wire Loom

The versatility of nylon split wire loom lends itself to a variety of applications. It is widely used in the following sectors

1. Automotive Industry In automotive manufacturing, nylon wire loom is utilized to protect wiring harnesses from heat and friction. It plays a vital role in ensuring that vehicle electrical systems remain intact and functional despite constant movement and exposure to elements.

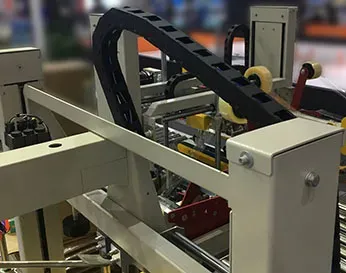

2. Industrial Settings Factories and manufacturing plants frequently employ nylon split wire loom to organize and protect the cabling associated with machinery and equipment. This prevents wear caused by machinery vibrations and ensures a neat, orderly workspace.

3. Electrical Installations In residential and commercial electrical installations, nylon wire loom is used to bundle and protect electrical cables. It can significantly reduce the risk of damage that might lead to short circuits or electrical fires.

nylon split wire loom

4. Telecommunications With the rapid growth of internet and communication technology, the telecom industry benefits from using nylon split wire loom to protect and manage the vast amounts of cables associated with data and communication networks.

Advantages of Using Nylon Split Wire Loom

The decision to use nylon split wire loom comes with several advantages

- Durability Unlike other materials, nylon offers substantial resistance to wear, heat, and chemicals. This durability translates into a longer lifespan for cables and wires housed within the loom.

- Flexibility Its flexibility allows for easy installation in tight spaces, making it ideal for intricate designs where space optimization is crucial.

- Ease of Use The split design permits quick access to wires for maintenance or modifications without the need for disassembly, saving time and effort for technicians.

- Accident Prevention By organizing wires, nylon split wire loom minimizes the risk of entanglement, which can lead to accidents and downtime in industrial settings.

- Aesthetics In addition to functionality, nylon wire loom offers a neat and polished appearance, improving the overall aesthetics of installations.

Conclusion

In conclusion, nylon split wire loom is a staple in various industries due to its exemplary protective qualities and ease of use. Its versatility, combined with the advantages it brings, underscores its importance in safeguarding wires and cables across multiple applications. Whether in vehicles, industrial settings, or telecommunications, embracing nylon split wire loom can enhance safety, efficiency, and durability in wiring solutions. As technology continues to evolve and industries expand, the role of nylon split wire loom will remain integral to maintaining organized and efficient systems.