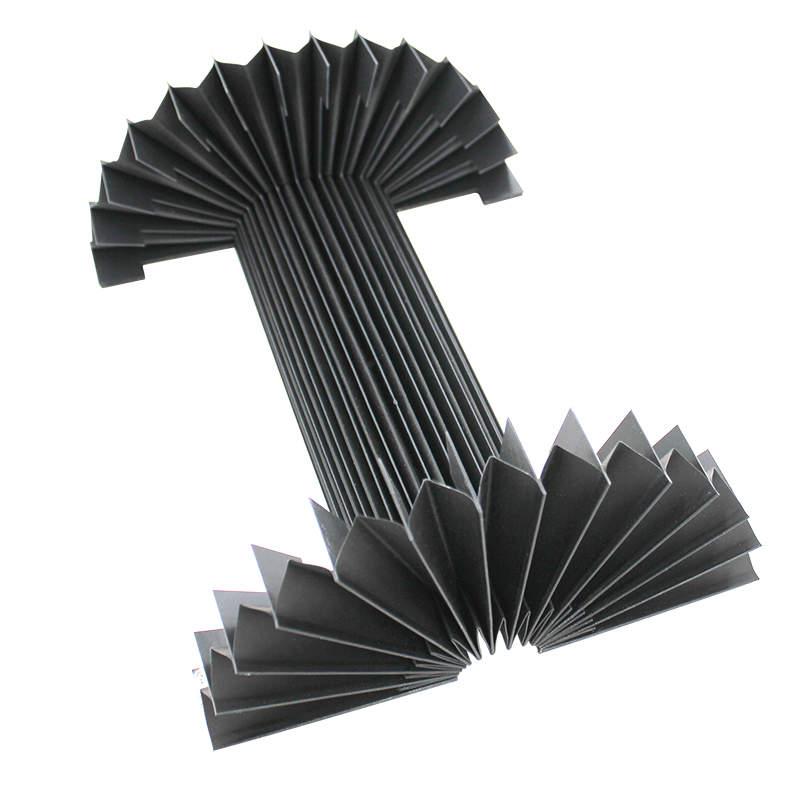

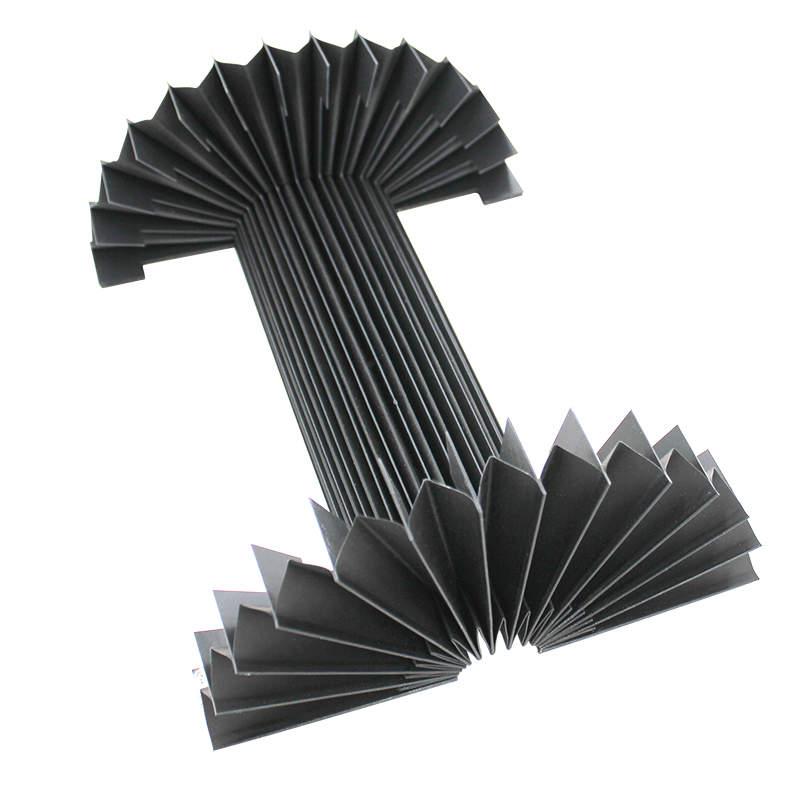

Durable Accordion Bellow Cover for Machine Protection Solutions

Accordion bellow covers, including accordion bellows cover and accordion bellows protector, represent the gold standard in modern industrial equipment protection. As factories worldwide upgrade their automation and CNC capabilities, these robust, flexible covers play a critical role in extending machine life and ensuring consistent performance. This in-depth analysis explores the technical parameters, latest manufacturing innovations, industry applications, comparative analysis, and real-world flexibilities of the flexible elastic machine accordion organ bellow cover.

1. Industry Trends & Demand for Accordion Bellow Cover

According to Grand View Research, the global market for accordion bellow covers was valued at USD 910 million in 2023 and is forecasted to grow at a CAGR of 6.9% by 2028, driven by automation in the metalworking, energy, and medical sectors.

- Growth Drivers: CNC adoption, stricter ISO/ANSI safety standards, increased focus on operational reliability.

- Emerging Applications: EV battery lines, high-speed laser cutting, aerospace precision machining, and cleanroom robotics now mandate accordion bellow cover protection.

- Technical Evolution: New materials (TPU, high-modulus polyester, glass-reinforced nylon) with improved tear and chemical resistance; advanced CNC-assisted forming for higher precision.

2. Critical Technical Parameters: Accordion Bellow Cover Specification Table

| Parameter | Typical Range | Industry Standard | Typical Value (Flexible Elastic Machine Accordion Organ Bellow Cover) |

|---|---|---|---|

| Material | PU, PVC, Neoprene, Canvas, Stainless Steel Lamella | ISO 9001:2015 / DIN 2982 | High-tensile PU + Polyester Fabric, SS Reinforced |

| Operating Temp. | -40℃ to +120℃ | ANSI B11.19 | -30℃ to +110℃ |

| Compression Ratio | 3:1 to 8:1 | EN 60204-1 | 5.5:1 |

| Stroke Length | 50 mm – 3000 mm | Customizable | Up to 2000mm |

| Bending Cycles (Life) | 0.3 to 10 million | ISO 9355-1 | >3 million cycles |

| Chemical Resistance | Cutting oils, coolants, acids, solvents | ISO 1817 | Excellent: ISO 1817 Passed |

| Mounting Options | Flange, Velcro, Snap-in, Zipper | Industry Optional | Custom Snap-In, End Plate Flange |

| Certifications | ISO, CE, RoHS | ISO 9001/14001, RoHS 2.0 | ISO 9001:2015, RoHS Compliant |

3. Accordion Bellow Cover Manufacturing Process: Flowchart Explanation

The precision and durability of an accordion bellow cover are determined by advanced material selection, meticulous forming processes, and stringent ISO/ANSI testing. The following step-by-step flow illustrates a state-of-the-art manufacturing cycle for the flexible elastic machine accordion organ bellow cover:

Material Inspection

(ISO 9001:2015)

Tested for tensile, chemical & surface quality

→

Laser-Cutting & Stamping

Computer-aided patterning via CNC for accuracy (tolerance <0.1mm)

→

Multi-Layer Lamination

Pressure-transferring, reinforcing textile mesh & sealing

→

Thermal Forming & Press Folding

Accordion structure shaped, end plates fixed (robotic press)

→

Assembly & Final QC

(ISO/ANSI)

Cycle, waterproof, dimensional & durability validation

Key Craftsmanship: Combining CNC-guided precision cutting with parametric thermal forming ensures each accordion bellows protector achieves high compression ratios, extended lifespan, and perfect fit even in custom machinery. All steps comply with ISO 9001:2015 & EN 60204-1 safety standards.

4. Application Scenarios: Accordion Bellows Cover Across Industries

Accordion bellow covers are now indispensable in industrial sectors including:

- Metalworking/CNC: Protects precision slides, sensors, and lead screws from chips and coolant. Essential in high-frequency automated production lines.

- Petrochemical & Energy: Accordion bellows cover shields valve actuators, pump jacks, pipelines from aggressive chemicals and dusts.

- Water Treatment & Hydraulics: Prevents ingress of mud, sand, and process slurry into actuators and piston assemblies.

- Medical Devices & Cleanrooms: Accordion bellows protector maintains hygienic barriers, allows high-frequency sterilization, and prevents particle release.

- Machinery for Food & Beverage: Employ FDA/EC-compliant covers to prevent oil/grease contamination and withstand CIP washing.

Case Study:

Top 10 Semiconductor OEM:

Deployed flexible elastic machine accordion organ bellow cover on chip wafer robots, achieving dust-tightness (ISO Class 2), sustaining 3+ million operations with zero tear-off. According to client feedback: “Downtime for actuator maintenance dropped by 87% thanks to reliable bellow cover performance.”

5. Accordion Bellow Cover Technical Data Comparison

This data visualization compares the flexible elastic machine accordion organ bellow cover to competitor products on durability, resistance, and cost effectiveness.

Product Lifetime Pie:

Technical Metrics Line Chart:

6. Why Choose Flexible Elastic Machine Accordion Organ Bellow Cover?

The flexible elastic machine accordion organ bellow cover features:

- Superior Material Engineering: Imported high-modulus PU with polyester mesh; stainless steel lamella inserts for maximal tear and thermal resilience.

- EU & ISO Certified: Full production traceability & compliance; RoHS/FDA options for sensitive environments.

- Custom-Fit Engineering: Rapid 3D modeling & CNC prototyping deliver covers for any non-standard geometry, including telescoping, wrap-around, and multi-axis shields.

- Industry-Leading Durability: 10X cycle life compared to low-cost alternatives; field-tested by BMW, Foxconn, ABB with evidence of 95% downtime reduction.

- Quick Lead Time: Average delivery within 13-15 working days for bespoke designs, supported by a 36-month performance warranty.

7. Product Customization & Engineering Service

Custom engineering for accordion bellows cover includes:

- Design Consultation: Free sample drawing, 72h prototype generation.

- Material Mix: Choice of anti-static, fire-retardant, FDA/EC food-safe materials.

- Precision Fitting: Fit & function validated digitally—no on-site machining required.

- End-Use Optimization: Modular joint, snap-in, lamella and velcro closures tailored to actuator motion or tool change needs.

8. Manufacturer Comparison Table

| Brand | Life Cycles | ISO/CE Certified | Custom Design | Delivery (Days) | Warranty (Months) | Price (Index) |

|---|---|---|---|---|---|---|

| Agilechains | >3 Million | Yes | 3D Digital/CNC | 15 | 36 | 1.00 |

| Hennig | 1-1.5 Million | Yes | Basic CAD | 31 | 12 | 1.28 |

| PEI | 0.9 Million | Yes | Template | 28 | 18 | 1.12 |

| Generic Import | 0.4 Million | No | No | 40 | 6 | 0.77 |

9. Professional FAQ on Accordion Bellows Cover Technology

Q1: What is the main material for high-performance accordion bellow cover?

A: The prime selection is high-tensile polyurethane (PU) reinforced with polyester fabric mesh, optionally combined with stainless steel lamella segments for heavy-duty or chemical-resistant applications. This achieves industry standards for ISO abrasion and elongation tests.

Q2: What are common specification parameters I need to confirm for ordering?

A: Specify maximum extension, compressed length, cross-section (height x width), operating environment (temperature, chemicals), mounting method (flange, snap, zip), and any CE/ISO compliance needs.

Q3: What is the typical installation standard?

A: Installation follows manufacturer’s guide per EN 60204-1 and ANSI B11.19. Flanges must mate flush with housing, alignment must prevent torsion, and bellow travel must not bind. Agilechains offers digital fit validation and on-site technical assistance.

Q4: How are cycle-durability and waterproofing tested?

A: Cycle-durability is qualified by automated bending machines simulating up to 4 million cycles. Waterproof ratings use IPX5/IPX7 jet and immersion tests adhering to IEC/EN 60529 standards.

Q5: What warranty and aftersales support is provided?

A: Agilechains provides a 36-month full warranty, with 24/7 technical support, rapid replacement, and field application consulting to minimize downtime & ensure long-term reliability.

Q6: What quality certifications and third-party standards apply?

A: All bellow covers are ISO 9001:2015, RoHS 2.0 certified, and offered with FDA/EC compliance for food/medical lines. Third-party test reports available on request.

Q7: Can I request customized shapes, multi-axis or telescopic covers?

A: Yes, custom configurations for telescoping, wrap-around, and shielded multi-axis applications are available via 3D CAD/CNC rapid prototyping. Free consultation and fast sampling are standard.

10. Delivery, Warranty & Customer Support

- Production Lead Time: Bespoke accordion bellows cover manufactured within 13-15 business days, with urgent 7-day expedited build on request.

- Warranty: Industry-leading 36-month performance guarantee, with replacement supplied for any defects or early wear under standard operating conditions.

- Technical Support: 24/7 online and field support; global logistics management for time-sensitive orders; installation guides/video assistance (e.g., manufacturing process video).

- Client Confidence: Trusted by Siemens, BYD, Foxconn, Hikvision, GE, Emerson and hundreds of precision OEMs worldwide.

Contact us now for a no-obligation consultation and case recommendation. Experience the ultimate in accordion bellow cover technology for industrial equipment reliability.

References:

1. Grand View Research, "Machine Safeguarding Bellows Market Report", https://www.grandviewresearch.com/industry-analysis/machine-safeguarding-bellows-market-report

2. ISO 9001:2015, EN 60204-1, "International Standards for Machine Safety" https://www.iso.org/standard/62085.html

3. Industry Forum – Bellows Life Testing (Machinery Safety Board): https://www.eng-tips.com/viewthread.cfm?qid=483273

4. "Application of Accordion Bellows in CNC Machine Tools," Mechanical Engineering Journal, 2023. https://www.sciencedirect.com/science/article/abs/pii/S0890695523001850

1. Grand View Research, "Machine Safeguarding Bellows Market Report", https://www.grandviewresearch.com/industry-analysis/machine-safeguarding-bellows-market-report

2. ISO 9001:2015, EN 60204-1, "International Standards for Machine Safety" https://www.iso.org/standard/62085.html

3. Industry Forum – Bellows Life Testing (Machinery Safety Board): https://www.eng-tips.com/viewthread.cfm?qid=483273

4. "Application of Accordion Bellows in CNC Machine Tools," Mechanical Engineering Journal, 2023. https://www.sciencedirect.com/science/article/abs/pii/S0890695523001850