Exploring the Connection Between Drag Link and Chain Mechanisms in Engineering

Understanding Drag Link Chains A Comprehensive Overview

In the world of machinery and mechanical systems, various components play crucial roles in ensuring smooth and efficient operation. One such component that often goes overlooked is the drag link chain. Although it may not be as widely recognized as gears or belts, the functionality and importance of drag link chains cannot be understated. This article aims to delve into the intricacies of drag link chains, exploring their design, applications, and benefits.

What is a Drag Link Chain?

A drag link chain is a type of mechanical linkage commonly used in conjunction with other components to facilitate movement and connection between different parts of a machine. Unlike traditional chains that are primarily designed for power transmission, drag link chains serve as a reliable means of connecting frameworks, allowing for controlled motion and stability.

Typically composed of durable materials such as steel, these chains consist of interlinked segments that form a flexible yet robust connection. The design of a drag link chain allows it to handle loads while minimizing friction and wear, a critical factor in the longevity and reliability of machinery.

Key Applications

Drag link chains find application across various industries due to their adaptability and versatile design. Here are some key sectors where they are commonly utilized

1. Automotive Industry In automotive applications, drag link chains are pivotal components within steering mechanisms. They help in connecting the steering wheel to the wheels of the vehicle, ensuring precise handling and responsiveness.

2. Construction Equipment Heavy machinery, such as excavators and bulldozers, often employs drag link chains to achieve controlled movement of arms and attachments. The chains facilitate the connection between various parts, allowing for nuanced operations that are essential in construction tasks.

3. Agricultural Machinery In farming equipment, drag link chains play a vital role in ensuring that different machine components work seamlessly together. They can connect parts of plows, harvesters, and other essential tools that rely on efficient operation for maximized productivity.

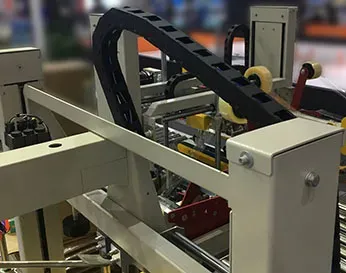

drag link chain

4. Conveying Systems Many industrial plants utilize drag link chains in conveying systems where objects need to be moved from one point to another. The chains can effectively link different conveyor segments, allowing for continuous and smooth operation throughout the production cycle.

Advantages of Drag Link Chains

The use of drag link chains offers numerous advantages that contribute to their prevalence across various industries

- Durability Constructed from high-quality materials, drag link chains are designed to withstand heavy loads and extreme conditions, making them a reliable choice for demanding applications.

- Flexibility The design of drag link chains allows for a significant range of motion, which is essential in applications requiring intricate manipulation of parts and machinery.

- Efficiency By minimizing friction during operation, drag link chains help in reducing wear and tear on connected components, leading to increased operational efficiency and lower maintenance costs.

- Cost-Effectiveness With their long lifespan and minimal maintenance needs, drag link chains can contribute to significant savings over time, making them a cost-effective solution for many industrial applications.

Conclusion

In summary, drag link chains are a fundamental yet often overlooked component of many mechanical systems. Their unique design and functionality make them essential in various industries, from automotive to agriculture. Understanding the role of these chains can help industries optimize their machinery, leading to improved performance and longevity. As technology continues to advance, the importance of drag link chains will likely remain significant, reinforcing their value in mechanical design and engineering. Embracing these components can lead to a future of enhanced efficiency and innovation across many sectors.