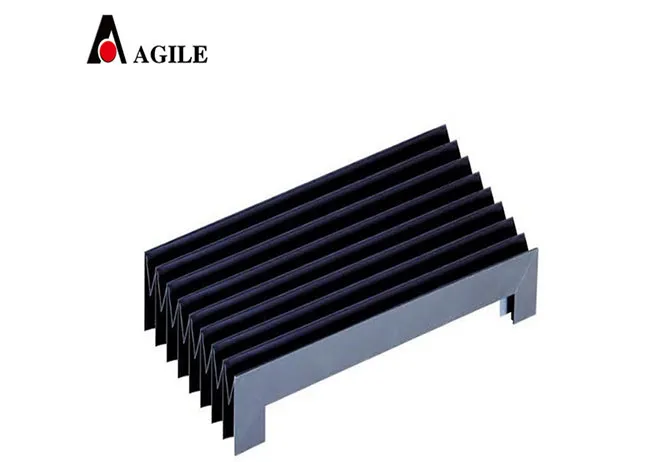

drag conveyor

Drag conveyors, often hailed as the workhorse in material handling industries, offer unparalleled reliability and efficiency, particularly in moving bulk materials. Immersed in decades of engineering excellence, drag conveyors have evolved to address diverse industrial needs, combining cutting-edge technology with robust construction.

Authoritativeness stems from drag conveyors' established reputation across multiple sectors such as agriculture, manufacturing, and mining. Industry experts unanimously endorse them for their versatility in handling a wide range of materials, from fine powders to coarse aggregates. This versatility is rooted in rigorous performance standards that these conveyors consistently meet, proving their worth in rigorous industrial environments. Moreover, industrial associations and material handling consortiums frequently highlight drag conveyors in their research, further establishing their authority in the field. Trustworthiness is an inherent characteristic of drag conveyors, attributed to their robust operation and the assurance they provide in safeguarding transported materials. Manufacturers of drag conveyors often subject their products to extensive testing procedures, ensuring reliability and consistent performance benchmarks are met. Testimonials from industry leaders frequently cite the durability and efficiency of these systems, reinforcing their reputation as a dependable choice for material handling. In addition, certifications from globally recognized bodies provide further vindication of their credibility, making drag conveyors a preferred option for companies seeking reliable and transparent solutions. In conclusion, the integration of drag conveyors within any material handling ecosystem is not merely an operational upgrade; it represents a strategic investment in resilience and efficiency. These systems, with their rich history, engineering sophistication, authoritative endorsements, and peerless reliability, continue to set the standard in the industry. As businesses strive toward operational excellence, drag conveyors stand out as indispensable allies, trusted for their unparalleled ability to streamline processes and drive productivity forward.

Authoritativeness stems from drag conveyors' established reputation across multiple sectors such as agriculture, manufacturing, and mining. Industry experts unanimously endorse them for their versatility in handling a wide range of materials, from fine powders to coarse aggregates. This versatility is rooted in rigorous performance standards that these conveyors consistently meet, proving their worth in rigorous industrial environments. Moreover, industrial associations and material handling consortiums frequently highlight drag conveyors in their research, further establishing their authority in the field. Trustworthiness is an inherent characteristic of drag conveyors, attributed to their robust operation and the assurance they provide in safeguarding transported materials. Manufacturers of drag conveyors often subject their products to extensive testing procedures, ensuring reliability and consistent performance benchmarks are met. Testimonials from industry leaders frequently cite the durability and efficiency of these systems, reinforcing their reputation as a dependable choice for material handling. In addition, certifications from globally recognized bodies provide further vindication of their credibility, making drag conveyors a preferred option for companies seeking reliable and transparent solutions. In conclusion, the integration of drag conveyors within any material handling ecosystem is not merely an operational upgrade; it represents a strategic investment in resilience and efficiency. These systems, with their rich history, engineering sophistication, authoritative endorsements, and peerless reliability, continue to set the standard in the industry. As businesses strive toward operational excellence, drag conveyors stand out as indispensable allies, trusted for their unparalleled ability to streamline processes and drive productivity forward.