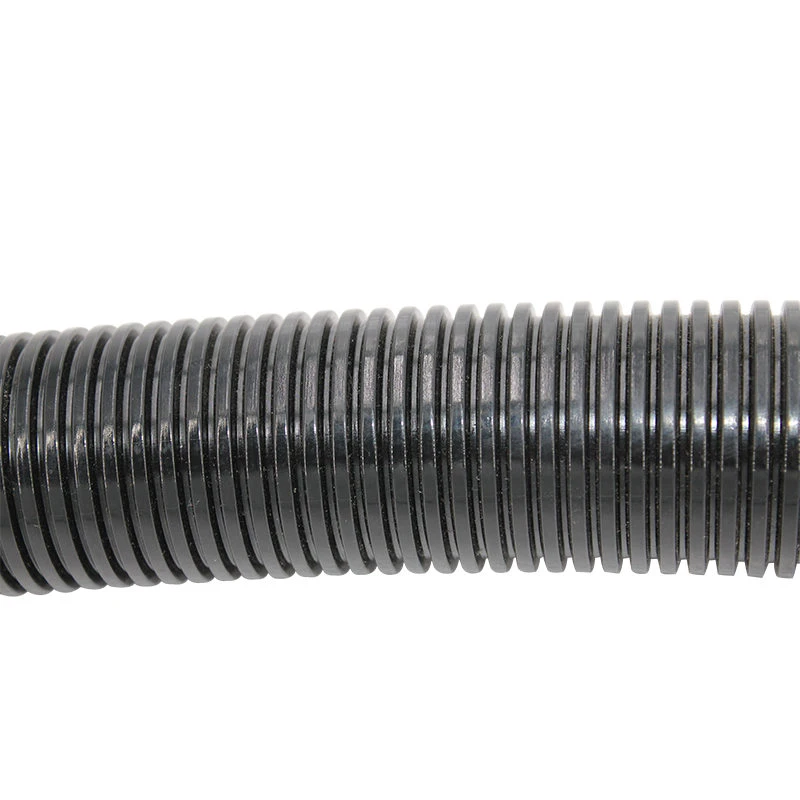

mini drag chain

Drag conveyors have become an integral part of industrial material handling solutions, revolutionizing the way bulk materials are transported across various sectors. As industries advance, the demand for reliable and efficient conveyor systems has surged, bringing drag conveyors to the forefront due to their robust design and operational efficiency.

In the realm of innovation, enhancements in drag conveyor technology continue to emerge, focusing on improving efficiency and reducing operational noise. Advanced materials and engineering solutions, such as self-cleaning chains and customizable conveyor layouts, are gaining traction, offering tailored solutions to industry-specific challenges. Industry experts assert that understanding the specific requirements of each application is paramount. As such, customization becomes a significant factor in the decision-making process. Whether it involves accommodating specific material characteristics or spatial constraints, drag conveyors can be designed to meet precise operational demands, ensuring seamless integration into existing workflows. The credibility of drag conveyors is reinforced by their track record and the endorsements of industry leaders who have witnessed firsthand their transformative impact on productivity. By aligning with reputable manufacturers and suppliers, companies can assure themselves of acquiring not only top-notch products but also comprehensive support and industry insight. As facilities aim to enhance their efficiency and sustainability, the demand for trusted and authoritative solutions like drag conveyors is expected to grow. Their blend of expertise, reliability, and flexibility positions them as a preferred choice for material handling needs, solidifying their reputation as essential components within modern industrial operations.

In the realm of innovation, enhancements in drag conveyor technology continue to emerge, focusing on improving efficiency and reducing operational noise. Advanced materials and engineering solutions, such as self-cleaning chains and customizable conveyor layouts, are gaining traction, offering tailored solutions to industry-specific challenges. Industry experts assert that understanding the specific requirements of each application is paramount. As such, customization becomes a significant factor in the decision-making process. Whether it involves accommodating specific material characteristics or spatial constraints, drag conveyors can be designed to meet precise operational demands, ensuring seamless integration into existing workflows. The credibility of drag conveyors is reinforced by their track record and the endorsements of industry leaders who have witnessed firsthand their transformative impact on productivity. By aligning with reputable manufacturers and suppliers, companies can assure themselves of acquiring not only top-notch products but also comprehensive support and industry insight. As facilities aim to enhance their efficiency and sustainability, the demand for trusted and authoritative solutions like drag conveyors is expected to grow. Their blend of expertise, reliability, and flexibility positions them as a preferred choice for material handling needs, solidifying their reputation as essential components within modern industrial operations.