drag chain use

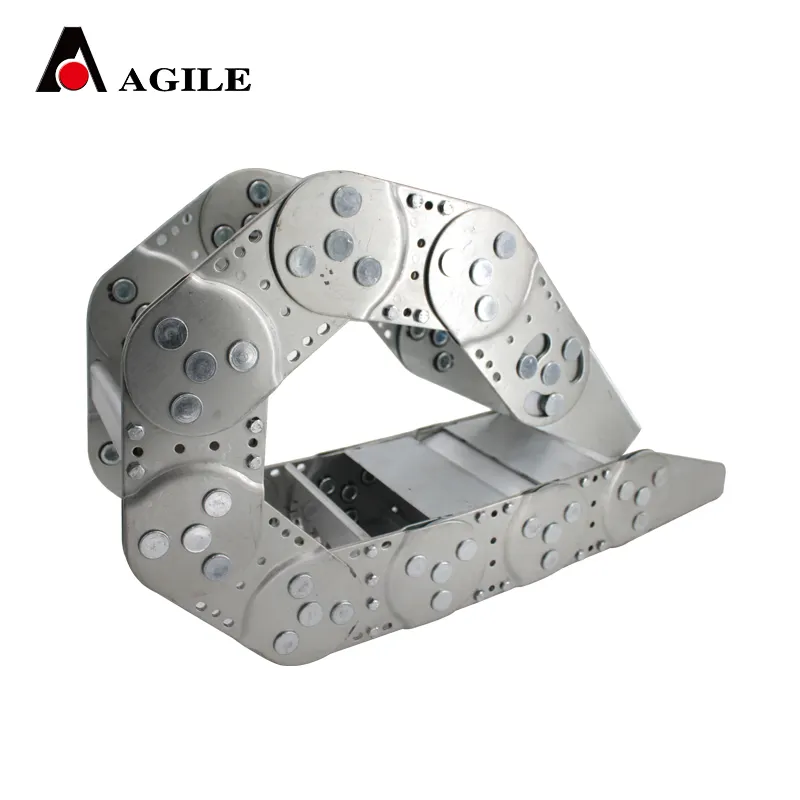

The utilization of drag chains has become increasingly prevalent in industries that prioritize the protection and organization of cables and hoses connected to machinery. While the basic concept of a drag chain—also known as a cable carrier—is straightforward, the intricacies of its applications and its vital role in efficient machinery operation often require deeper exploration.

Real-world experience illuminates several case studies where deploying the appropriate drag chain solution led to remarkable improvements in operational efficiency. In high-speed robotic automation, for instance, the agility and precision provided by the right drag chain can drastically reduce cycle times while maintaining the system's integrity. Similarly, industries relying on heavy machining processes report improved cable longevity and reduced frequency of halts for cable repairs or replacements, contributing to substantial cost savings. Establishing oneself as an authority in the world of drag chain applications requires staying abreast of technological advancements and innovations in the industry. With the advent of Internet of Things (IoT) technology and the increasing automation of industrial processes, smart drag chains equipped with sensors to monitor and report on cable conditions in real time are emerging. These innovations are transforming preventive maintenance strategies, enabling a shift towards predictive maintenance that optimizes operational uptime and efficiency. Trustworthiness in the domain of drag chain solutions is derived from a proven track record of efficiency, safety, and cost-effectiveness. Leveraging industry certifications and compliance with international standards underscores a provider's commitment to quality and safety. Engagement in customer education and support further solidifies trust by empowering clients to make informed decisions tailored to their unique challenges and requirements. In conclusion, the role of drag chains extends beyond simple cable management; it is integral to enhancing efficiency, safety, and longevity of machinery in demanding industrial environments. Through the competent selection, meticulous maintenance, and a thorough understanding of industry needs, businesses can harness the full potential of drag chains to maximize their operational efficacy. By doing so, they not only safeguard their equipment investments but also drive forward innovation and productivity in their respective sectors.

Real-world experience illuminates several case studies where deploying the appropriate drag chain solution led to remarkable improvements in operational efficiency. In high-speed robotic automation, for instance, the agility and precision provided by the right drag chain can drastically reduce cycle times while maintaining the system's integrity. Similarly, industries relying on heavy machining processes report improved cable longevity and reduced frequency of halts for cable repairs or replacements, contributing to substantial cost savings. Establishing oneself as an authority in the world of drag chain applications requires staying abreast of technological advancements and innovations in the industry. With the advent of Internet of Things (IoT) technology and the increasing automation of industrial processes, smart drag chains equipped with sensors to monitor and report on cable conditions in real time are emerging. These innovations are transforming preventive maintenance strategies, enabling a shift towards predictive maintenance that optimizes operational uptime and efficiency. Trustworthiness in the domain of drag chain solutions is derived from a proven track record of efficiency, safety, and cost-effectiveness. Leveraging industry certifications and compliance with international standards underscores a provider's commitment to quality and safety. Engagement in customer education and support further solidifies trust by empowering clients to make informed decisions tailored to their unique challenges and requirements. In conclusion, the role of drag chains extends beyond simple cable management; it is integral to enhancing efficiency, safety, and longevity of machinery in demanding industrial environments. Through the competent selection, meticulous maintenance, and a thorough understanding of industry needs, businesses can harness the full potential of drag chains to maximize their operational efficacy. By doing so, they not only safeguard their equipment investments but also drive forward innovation and productivity in their respective sectors.