drag chain suppliers

Understanding Drag Chain Suppliers The Backbone of Efficient Cable Management

In the modern industrial landscape, the efficient management of cables and wires is critical for maintaining operational efficiency and safety. This is where drag chains, also known as energy chains or cable carriers, come into play. Drag chain suppliers play a vital role in providing these components that ensure the smooth movement of cables and hoses in various applications, from manufacturing and robotics to construction and transportation.

What is a Drag Chain?

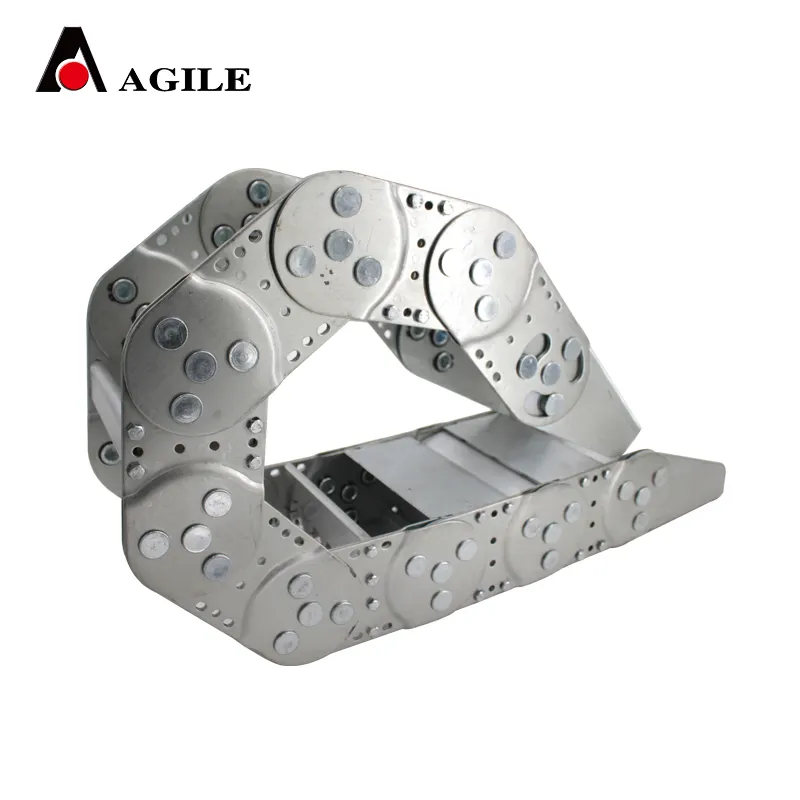

A drag chain is a flexible, protective structure that guides and supports moving cables and hoses. These chains are designed to minimize wear and tear on cables, reduce the risk of tangling, and maintain organization in environments where movement is frequent and components are exposed to various stresses. They can be found in equipment such as CNC machines, robotic arms, conveyor systems, and more.

The Importance of Drag Chain Suppliers

Choosing the right drag chain supplier is essential for ensuring the overall performance and longevity of machinery. Suppliers provide not only a variety of drag chain types but also the necessary accessories and support systems that enhance functionality. Factors such as material quality, flexibility, load capacity, and environmental resistance are crucial when selecting a drag chain. Suppliers typically offer custom solutions tailored to specific industry needs, which further elevates their importance.

Types of Drag Chains

There are several types of drag chains available in the market, each designed for specific applications. Some of the most common types include

1. Open Chain Design This is suited for lighter applications where accessibility and ease of installation are priorities. Open designs allow for quick access to cables, making maintenance easier.

drag chain suppliers

2. Closed Chain Design Closed chains offer enhanced protection against environmental factors, making them ideal for outdoor or industrial settings. They prevent contamination and damage from dust, moisture, and chemicals.

3. Heavy-Duty Drag Chains Designed for applications with significant weight and strain, these drag chains are built to withstand robust environments and are often used in industries like construction and mining.

4. Robot Chains Specifically engineered for robotic applications, these chains allow for high flexibility and minimal bending radius, crucial for multi-axis movements.

Choosing the Right Supplier

When selecting a drag chain supplier, there are several factors to consider

- Product Range A good supplier will offer a wide variety of drag chains and accessories to cater to different needs. - Quality Assurance Check for certifications and quality standards that ensure the chains meet industry benchmarks. - Customization Options Many industries have specific requirements; a supplier that offers customization can better meet unique project specifications. - Customer Support and Service Reliable customer service can significantly impact the efficiency of project implementation, making a responsive supplier invaluable.

Conclusion

In summary, drag chains are essential components that enhance cable management in various industries. Drag chain suppliers provide the necessary products and expertise to ensure optimal performance and longevity of these systems. By understanding the types of drag chains available and the critical factors in selecting a supplier, businesses can significantly improve their operational efficiency and reduce downtime, ultimately leading to increased productivity and cost savings.