Selecting the Right Size for Your Drag Chain Applications Guide

Understanding Drag Chain Size Charts A Comprehensive Guide

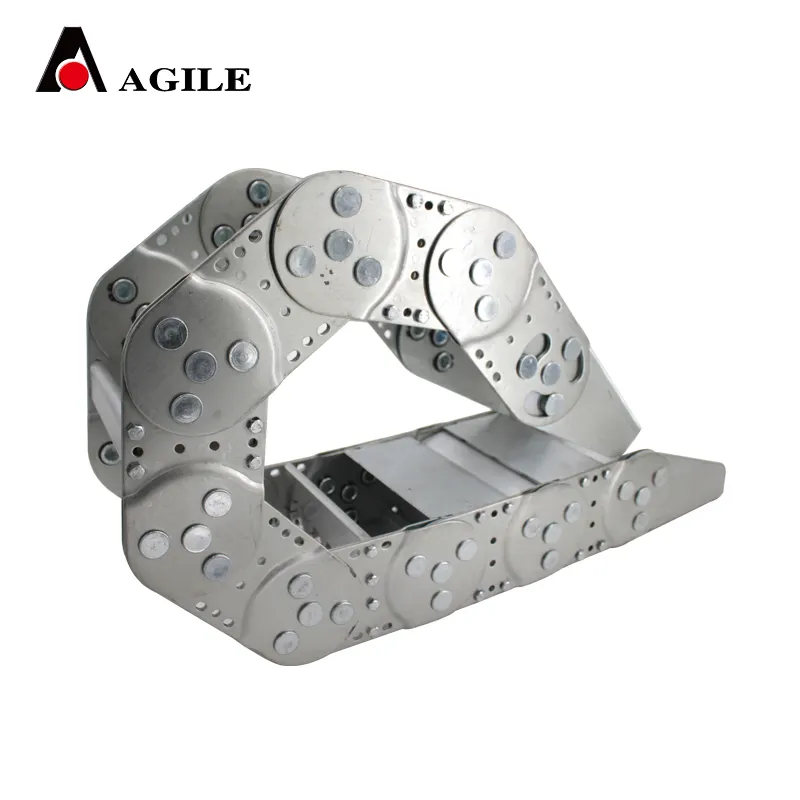

In various industries, drag chains are essential components that manage cables and hoses, ensuring smooth operation and safety in machinery. A drag chain, often referred to as a cable carrier or drag chain conveyor, protects and organizes moving cables and hoses in different applications, from industrial automation to robotics. However, selecting the right drag chain size can be daunting without the proper guidance. This is where drag chain size charts come into play.

What is a Drag Chain?

A drag chain is a flexible system designed to guide and protect cables and hoses as they move with machinery. These chains consist of links that create a pathway through which cables can move freely, shielding them from wear, abrasion, and entanglement. Drag chains are found in various settings, including CNC machines, conveyor systems, and automated production lines. The right size and type of drag chain can significantly impact the efficiency and longevity of the equipment.

Importance of Drag Chain Size Charts

Drag chain size charts provide essential information about the dimensions and specifications of different drag chains. These charts help users determine the appropriate size based on factors such as cable thickness, chain length, and the operating environment. Using the correct size drag chain is crucial; a chain that is too small may lead to kinks or damage to the cables, while an oversized chain can result in unnecessary bulk and weight.

Key Elements of Drag Chain Size Charts

1. Chain Width The width of the chain is pivotal for determining how many cables or hoses it can accommodate. Size charts typically display a range of widths to cater to various applications. Users must measure the combined diameter of the cables and hoses to find the appropriate width.

2. Chain Height The height of the drag chain affects its capacity and stability. Taller chains can hold more cables but may be less stable in certain configurations. Size charts will often include height options to suit different setups.

3. Chain Length Depending on the application, the length of the drag chain is vital. Some charts provide recommendations based on the working distance and the amount of travel needed for the cables.

drag chain size chart

4. Bending Radius The bending radius indicates how sharply a drag chain can turn without straining the cables within it. A smaller radius allows for more compact designs but requires careful consideration of the cables’ flexibility and durability.

5. Load Capacity Size charts often include load capacity information, indicating how much weight the drag chain can support. This factor is crucial for ensuring that the chosen solution can handle the operational demands without risking failure.

6. Material and Environment Considerations Different materials can significantly affect performance. Charts may provide options based on environmental factors such as temperature, exposure to chemicals, or outdoor use. Understanding these parameters helps users select the best options for their specific conditions.

Steps to Use Drag Chain Size Charts

1. Identify Your Needs Assess the specific requirements of your application, including the number of cables, their diameter, and the working environment.

2. Consult the Chart Once you have the necessary measurements, refer to a drag chain size chart. Locate the appropriate section, taking note of suggested widths, heights, and lengths.

3. Check Additional Specifications Review the load capacities and bending radius to ensure you select a chain compatible with your machinery’s movements.

4. Make an Informed Decision With all the necessary information at hand, choose a drag chain that best suits your application.

Conclusion

Understanding and utilizing drag chain size charts are essential for anyone involved in managing cables and hoses in machinery. By correctly assessing the specifications provided in these charts, users can ensure optimal performance, safety, and efficiency in their operations. Investing time in this selection process pays dividends in the long run, preventing costly errors and equipment failures. Whether you are involved in manufacturing, robotics, or any field that requires cable management, making informed decisions about drag chain size will lead to smoother operations and enhanced productivity.