CNC Machine Tool Cable Management Solutions with Drag Chains for Efficient Operation

Understanding Drag Chains for CNC Machines

Drag chains, often referred to as energy chains or cable carriers, play a crucial role in the efficient operation of CNC (Computer Numerical Control) machines. These systems are designed to manage and protect the numerous cables and hoses that power the machine's movements, ensuring seamless operation and preventing wear and tear.

Understanding Drag Chains for CNC Machines

Drag chains provide a controlled pathway for these cables and hoses, allowing them to move freely with the machine while minimizing the risk of damage. Typically made from durable plastic or steel, drag chains come in various shapes and sizes, catering to the specific needs of different CNC systems. They are flexible and robust, designed to withstand the rigors of industrial environments.

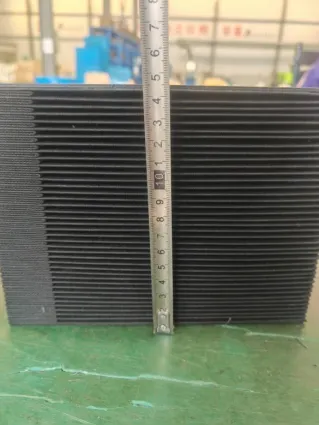

drag chain for cnc

One of the primary advantages of using drag chains in CNC applications is the enhancement of movement efficiency. By organizing cables and hoses, drag chains not only prevent tangling but also reduce friction, which can lead to smoother machine operations. This, in turn, translates into better overall performance and product quality.

Moreover, drag chains significantly contribute to the longevity of the cables and hoses they protect. By minimizing wear and tear, these systems help reduce maintenance costs and extend the life of the associated components. This is especially important in high-precision CNC operations, where accuracy and reliability are paramount.

When selecting a drag chain for a CNC machine, several factors should be considered, including the size and weight of the cables or hoses, the required bend radius, and the machine's operating environment. It’s also essential to ensure that the drag chain can accommodate future upgrades or changes in the system.

In conclusion, drag chains are an indispensable component in the world of CNC machining. They ensure the orderly management of cables and hoses, enhance operational efficiency, and prolong the life of critical machine components. By investing in quality drag chains, businesses can improve productivity and maintain high standards in their manufacturing processes.