drag chain for cnc

Understanding Drag Chains for CNC Machines Essential Components for Efficient Operation

In the realm of CNC (Computer Numerical Control) machining, efficiency and precision are paramount. Among the myriad components that contribute to the smooth operation of CNC machines, drag chains play a crucial role. These sturdy, flexible conduits are responsible for managing and protecting cables, hoses, and other components that are vital for the machine's functioning. In this article, we will explore the key features, benefits, and considerations regarding drag chains in CNC applications.

What Are Drag Chains?

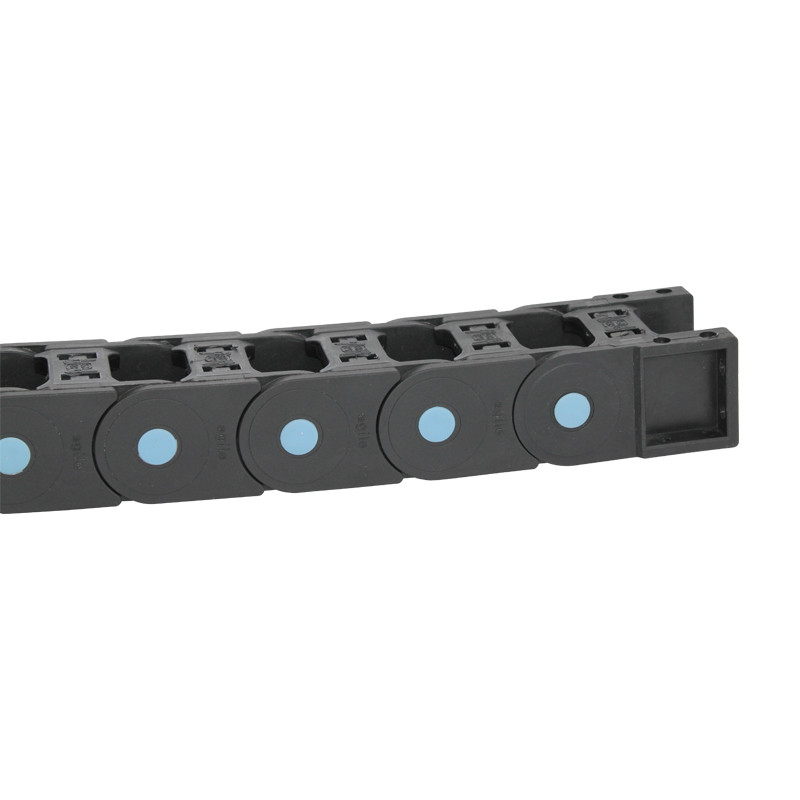

Drag chains, also known as energy chains or cable carriers, are engineered systems designed to organize and protect moving cables and hoses in various industrial applications, notably in CNC machinery. They consist of a series of interconnected links that can bend in multiple directions without kinking or damaging the cables inside.

These chains are mounted on moving components of CNC machines, allowing cables to move freely as the machine operates. This prevents tangles, reduces wear and tear, and ultimately enhances the reliability and longevity of the cables.

Key Features of Drag Chains

1. Flexibility and Versatility Drag chains are designed to accommodate different types of cables and hoses, allowing for custom configurations based on specific machine requirements. Their flexibility enables them to navigate tight spaces and bends without compromising the integrity of the contents.

2. Durability Made from robust materials such as nylon, polypropylene, or steel, drag chains are engineered to withstand harsh environments. High humidity, dust, and exposure to chemicals are common in CNC machining; hence, many drag chains are designed for durability and resistance to wear.

3. Modular Design Most drag chains feature a modular design, allowing for easy assembly and disassembly. This adaptability makes maintenance and cable replacement straightforward and efficient, minimizing downtime.

4. Noise Reduction The movement of cables and hoses can generate noise, which may be undesirable in a working environment. Many drag chains are designed to mitigate this noise, ensuring a quieter operation, which contributes to a better working environment.

drag chain for cnc

Benefits of Utilizing Drag Chains

1. Enhanced Cable Management Keeping cables organized prevents tangling and damage, which can lead to costly repairs and downtime. Drag chains facilitate efficient cable routing, ensuring that everything remains orderly.

2. Increased Safety Properly managed cables and hoses reduce the risk of tripping hazards and accidental disconnections, contributing to a safer working environment. This is particularly important in CNC machining, where hazards can come from moving parts and machinery.

3. Improved Productivity By streamlining the management of essential components, drag chains contribute to smoother operations. Machines can run without interruptions, which directly impacts productivity and efficiency.

4. Longevity of Components With drag chains protecting cables and hoses, the wear and tear caused by movement is significantly reduced. This prolongs the lifespan of these components, leading to lower replacement costs and greater reliability of the CNC machines.

Considerations When Selecting Drag Chains

When incorporating drag chains into a CNC setup, there are several factors to consider. The size and weight of the cables, the expected range of motion, and the environmental conditions in which the machine will operate all play a critical role in the selection process.

Additionally, evaluating the installation space and the specific application requirements will help determine the most suitable type of drag chain. Proper sizing is essential to ensure that the drag chain can accommodate the cables without excessive strain.

Conclusion

Drag chains are integral components of CNC machines that enhance operational efficiency, safety, and reliability. By providing organized cable management and protection, they play a pivotal role in maintaining the functionality of CNC machining. Understanding the features, benefits, and selection criteria of drag chains helps manufacturers optimize their CNC operations, ultimately leading to better products and increased profitability. As industries continue to evolve, the importance of these simple yet effective solutions cannot be overstated in the ever-competitive landscape of manufacturing technology.