Choosing the Best Drag Chain Solutions for Your CNC Machine Setup

Understanding Drag Chains for CNC Machines

In the realm of CNC (Computer Numerical Control) machining, precision and reliability are paramount. As technology has advanced, manufacturers have developed various components to enhance the efficiency and safety of CNC operations. One such critical component is the drag chain, an often-overlooked but essential part of CNC machinery.

What is a Drag Chain?

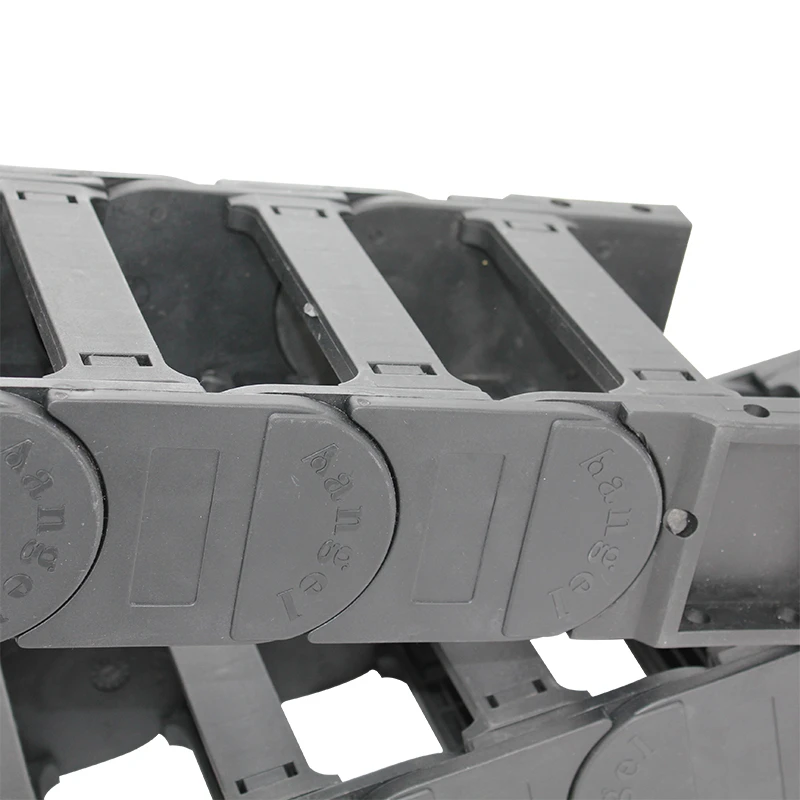

A drag chain, also known as a cable carrier or drag chain system, is designed to manage and protect moving cables and hoses within CNC machines. These chains are invaluable in environments where machinery involves significant movement, ensuring that electrical and hydraulic lines do not become tangled or damaged during operation. Drag chains are typically made from durable materials such as nylon or polypropylene, providing strength and flexibility.

The Purpose of Drag Chains

The primary function of a drag chain is to create an organized pathway for wiring and hoses. In the absence of a drag chain, cables would be prone to wear, abrasion, and entanglement, leading to potential downtime and costly repairs. Drag chains keep everything neat and secure, allowing for smooth machine operation. Furthermore, by preventing damage to cables, these systems enhance the longevity of electrical and hydraulic components.

Components of a Drag Chain

A typical drag chain consists of several key components

1. Links The chain is made up of interlocking links that form a flexible, yet strong carrier system. These links often come in various shapes and sizes, allowing manufacturers to choose the right design for their specific needs.

2. End Connectors These connectors secure the drag chain to the machine frame, ensuring it remains stable during operation.

3. Guide Channels Many drag chains feature internal guide channels to keep cables organized and prevent them from twisting or tangling.

drag chain for cnc

Advantages of Using Drag Chains

1. Protection Drag chains provide essential protection for cables and hoses from mechanical damage, dirt, and other environmental factors.

2. Enhanced Movement By keeping cables organized and free from tangles, drag chains enable smoother and more efficient movement of CNC machines, contributing to better machining accuracy.

3. Safety Properly managed cables reduce the risk of tripping hazards and accidental disconnections, enhancing workplace safety.

4. Reduced Downtime By preventing cable damage, drag chains help minimize breakdowns and maintenance needs, thus boosting productivity.

5. Customization Drag chains can be customized to meet the specific needs of different CNC applications, including size, shape, and internal configurations.

Installation and Maintenance

Installing drag chains in CNC machinery is generally a straightforward process, but it is essential to ensure they are correctly configured to avoid strain on hoses and cables. Regular maintenance checks can help identify wear and tear on the drag chain itself, allowing for timely replacements before serious issues arise.

Conclusion

Drag chains are a vital component in the efficiency and safety of CNC machines. With their ability to organize and protect cables and hoses, they contribute significantly to streamlined operations and reduced maintenance costs. As the manufacturing industry continues to evolve, the role of drag chains will remain critical in ensuring that CNC machinery operates at its best. Investing in quality drag chains is a step toward achieving optimal performance and reliability in any CNC setup.