Choosing the Right Drag Chain for CNC Machines and Their Applications

Understanding Drag Chains for CNC Applications

In modern manufacturing and automation, CNC (Computer Numerical Control) machines have revolutionized the way we approach precision machining. These sophisticated machines are capable of executing intricate designs with high accuracy, making them pivotal in various industries from aerospace to automotive. However, as with any advanced technology, the functionality of CNC machines is reliant on ancillary components that enhance their performance. One such component is the drag chain, a vital element that ensures efficient management of cables and hoses, ultimately contributing to the smooth operation of CNC machinery.

What is a Drag Chain?

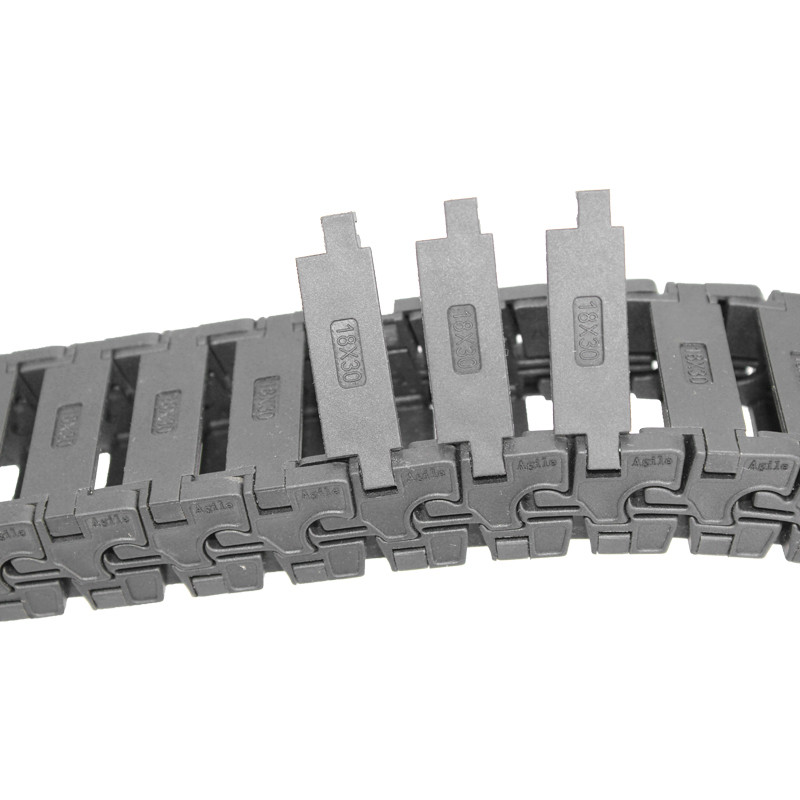

A drag chain, also known as a cable carrier or energy chain, is a system designed to guide and protect cables, hoses, and other flexible conduits. In CNC applications, these chains are essential for organizing the wires that power the machine and control its various functions. A drag chain comprises interconnected links that create a flexible channel for cables, allowing for unrestricted movement while maintaining strain relief and cable protection.

Importance of Drag Chains in CNC Machines

1. Cable Management A CNC machine typically has numerous cables running from the control panel to various moving parts such as the spindle and axes. A chaotic arrangement can lead to tripping hazards, tangling, and premature wear. Drag chains neatly organize these cables, ensuring they remain separated and easily accessible.

2. Protection of Cables and Hoses Cables and hoses are often subject to wear and tear due to constant movement, bending, and exposure to harsh working environments. Drag chains protect these essential components from mechanical damage, chemical exposure, and environmental contaminants, thereby extending their lifespan.

3. Improved Mobility CNC machines often have significant moving parts that require freedom of motion. Drag chains facilitate this by allowing cables to move smoothly and without kinking or tangling. This flexibility is crucial for maintaining the precision and speed that CNC operations demand.

4. Reduced Maintenance With a well-designed drag chain in place, the need for frequent maintenance and replacement of damaged cables decreases significantly. This results in reduced downtime and lower operational costs, which is vital for businesses looking to maximize productivity.

drag chain for cnc

5. Enhanced Safety A well-organized system not only aids in machine performance but also contributes to workplace safety. By preventing cables from dragging on the floor or getting caught in machinery, drag chains minimize the risk of accidents that can result in injury to operators.

Selecting the Right Drag Chain

Choosing the appropriate drag chain for a CNC application involves considering several factors

- Load Capacity Ensure that the drag chain can support the weight of the cables and hoses it will carry. Each drag chain has a specified load capacity, which should not be exceeded.

- Motion Requirements Consider the specific movements of the CNC machine. Drag chains should accommodate the range of motion, including bending radius and travel distance.

- Environmental Conditions Take into account any environmental factors that may affect the drag chain’s performance, such as temperature fluctuations, exposure to chemicals, or presence of coolant fluids.

- Cable Type and Size Different cables have unique requirements regarding diameter and flexibility. The drag chain must be compatible with the types of cables you intend to use.

Conclusion

In summary, drag chains play a crucial role in the operational efficiency and safety of CNC machines. They offer an effective solution for cable management, protection, and mobility, which are essential for maintaining the precision and reliability that CNC operations demand. By investing in high-quality drag chain systems, manufacturers can enhance their CNC machine’s performance, reduce maintenance costs, and ensure a safer working environment. As technologies continue to evolve, drag chains will remain an indispensable component in the world of CNC machining, contributing to the ongoing pursuit of innovation and excellence in manufacturing.