drag chain for cnc

Understanding Drag Chains for CNC Applications

Drag chains, often referred to as cable carriers or energy chains, are essential components in CNC (Computer Numerical Control) applications. These systems are designed to protect and manage the various cables and hoses that power and control the machinery. With the rise of automation and the increasing complexity of CNC systems, drag chains have become vital for ensuring efficient and safe operation.

What is a Drag Chain?

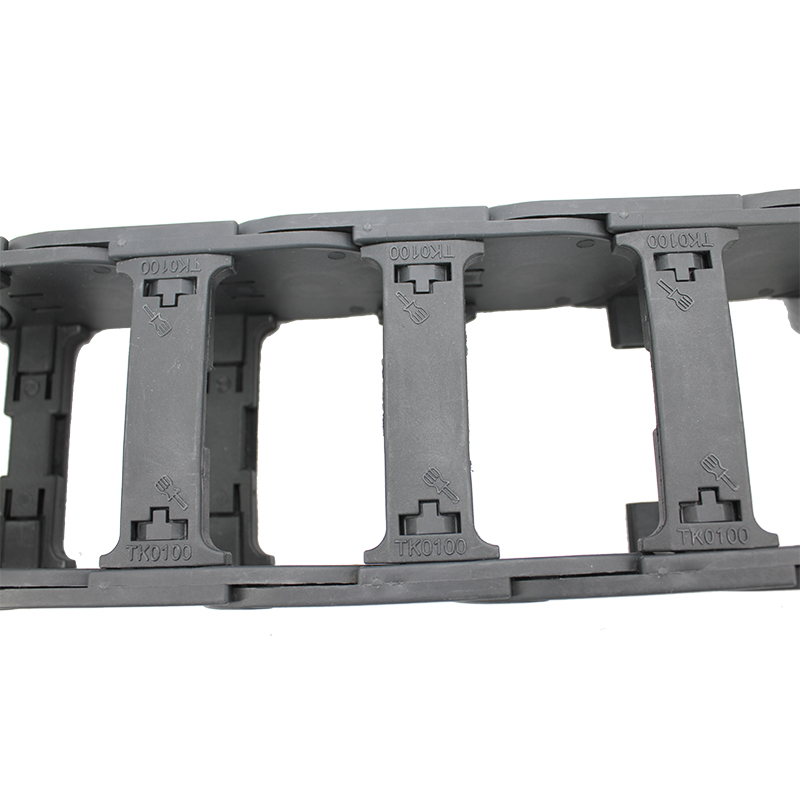

A drag chain is a flexible conduit that allows for the smooth movement of cables and hoses while minimizing wear and tear. These chains are constructed from durable materials such as plastic or metals, which can withstand the rigors of industrial environments. They feature a series of interconnected links that can bend and flex, allowing them to travel with the moving parts of the CNC machine.

The Importance of Drag Chains in CNC Applications

In CNC operations, machines often have multiple moving parts that require simultaneous power and signal transmission. Traditional cord management can lead to tangled wires, increased friction, and potential damage, which can result in costly downtime. Drag chains streamline this process by providing a dedicated pathway for cables and hoses, reducing the risk of entanglement and ensuring that each connection remains intact.

Additionally, drag chains help protect cables from environmental factors such as dust, debris, and mechanical wear. This protection is vital as it prolongs the lifecycle of electrical components, ultimately minimizing maintenance costs and enhancing the reliability of CNC machinery.

Benefits of Using Drag Chains

drag chain for cnc

1. Organization and Efficiency Drag chains keep cables neatly organized, preventing tangling and confusion. This organization not only facilitates faster setup times but also simplifies troubleshooting and maintenance.

2. Flexibility and Range of Motion Drag chains are designed to accommodate a wide range of movement, whether in linear slides, rotary axes, or multi-dimensional applications. This adaptability enables smooth operation across various CNC tasks.

3. Customization Options Many manufacturers offer customizable drag chains to fit specific applications. These options can include variable lengths, sizes, and internal divisions, allowing businesses to tailor solutions to their unique requirements.

4. Safety Considerations By enclosing and securing cables, drag chains help reduce the risk of accidents related to exposed wiring. This safety feature is crucial in high-speed machining environments where the risk of damage is significant.

Choosing the Right Drag Chain

When selecting a drag chain for a CNC application, several factors must be considered. These include the types of cables being used, the degree of movement required, and the environment in which the machine operates. Consulting with manufacturers or specialized suppliers can provide valuable insights, ensuring that the chosen drag chain meets operational needs effectively.

Conclusion

In the fast-paced world of CNC machining, drag chains play a pivotal role in enhancing efficiency and reliability. By effectively managing and protecting cables and hoses, these systems ensure smoother operations, reduce maintenance costs, and enhance safety. As technology continues to evolve, the importance of drag chains in CNC applications will only grow, making them a critical consideration for manufacturers looking to optimize their processes.