drag chain for cnc

Understanding Drag Chains for CNC Machines

In the world of CNC (computer numerical control) machining, efficiency and precision are paramount. One often overlooked component, essential for the smooth operation of CNC systems, is the drag chain. A drag chain, also known as a cable carrier or energy chain, is a vital accessory that organizes and protects cables, hoses, and other flexible connections, ensuring that the machinery operates without interruption.

What is a Drag Chain?

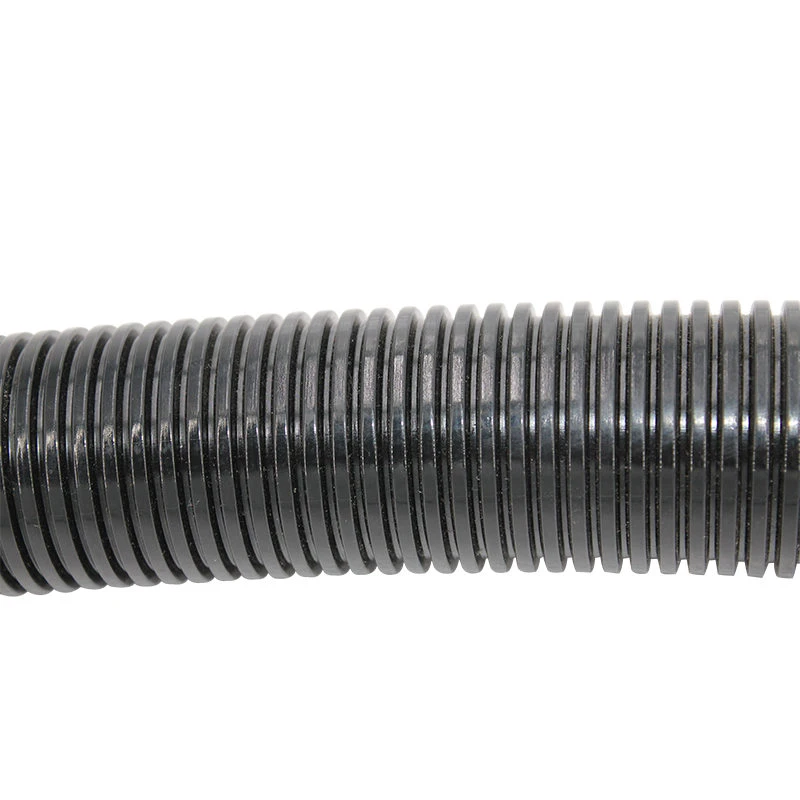

A drag chain is a flexible channel made up of interconnected links that houses cables and hoses. It serves to guide and protect these components as they move with the dynamic motion of CNC machines. Drag chains are designed to allow for smooth and unobstructed movement, minimizing wear and tear on the cables they carry. Their design not only aids in the extension and retraction of cables but also prevents tangling or damage that can occur during movement.

Importance of Drag Chains in CNC Applications

In CNC machining, the motion of the cutting tools and the table can be extensive and varies in direction. Without drag chains, cables could become entangled or damaged, leading to machine downtime and potential safety hazards. The use of drag chains provides several benefits

1. Protection They shield cables from physical damage due to abrasion, cuts, and environmental factors such as oil, dirt, and water.

2. Organization Drag chains help maintain a tidy work environment by organizing cables and hoses. This reduces clutter and facilitates easier inspection and maintenance.

3. Increased Lifespan By reducing mechanical stress on cables, drag chains enhance the lifespan of the electrical and pneumatic components, resulting in lower replacement costs over time.

4. Efficiency A well-organized system enables smoother operation of the CNC machine, thus improving cycle times and overall productivity.

Types of Drag Chains

drag chain for cnc

There are various types of drag chains available, tailored for different applications. Some common types include

- Plastic Drag Chains Lightweight and typically used for lighter applications, plastic drag chains offer excellent flexibility and are resistant to many chemicals.

- Steel Drag Chains Stronger and more durable, steel drag chains are used in heavy-duty applications and environments where additional strength is required.

- Flexible Drag Chains These chains can adapt to tight bends and curves in the workspace, which is particularly beneficial for machines with complex movement paths.

When selecting a drag chain, one needs to consider factors such as the motion range, load capacity, working environment, and the specific type of cables or hoses being used.

Installation and Maintenance

Installing a drag chain requires careful planning. The chain should be mounted in such a way that it does not impede the machine's movement. Additionally, proper spacing and support are crucial to prevent sagging or excessive bending, which can lead to premature wear.

Regular maintenance of the drag chains is also critical. Operators should routinely check for signs of wear, tension, and alignment. Keeping the chain clean and lubricated can further enhance its performance and lifespan.

Conclusion

In conclusion, drag chains play a significant role in the efficiency and functionality of CNC machines. By providing essential protection and organization for cables and hoses, they contribute to smoother operation and reduced downtime. When considered as part of the overall design and maintenance of CNC equipment, drag chains can enhance productivity and reduce long-term costs. As CNC technology continues to evolve, the importance of these components will only become more significant, underscoring the need for thoughtful integration in modern machining practices.