drag chain cable tray

Understanding Drag Chain Cable Trays Essential Components for Efficient Cable Management

In industrial and manufacturing settings, the management of electrical cables and wires is crucial for ensuring efficiency, safety, and organization. One popular solution for addressing these needs is the drag chain cable tray, a versatile and practical system designed to support, protect, and manage cables in a variety of environments.

What is a Drag Chain Cable Tray?

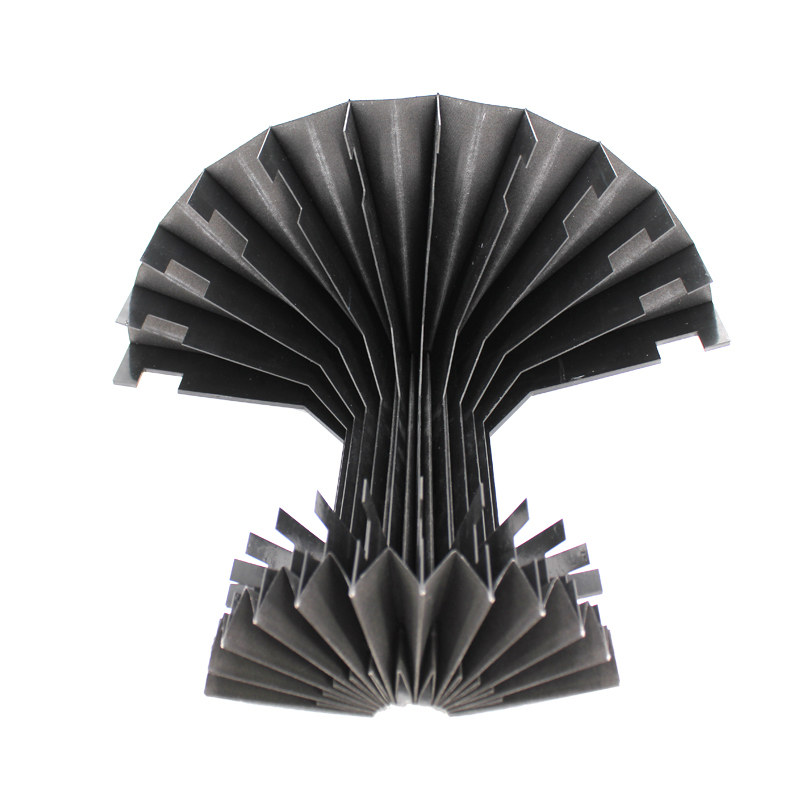

A drag chain cable tray is a type of cable management system that consists of a series of interconnected links or plates, forming a chain-like structure. This setup allows for the controlled movement of cables while minimizing stress and wear. The drag chain is primarily used in applications where cables need to move continually or in dynamic conditions, such as in automated machinery, robotics, and conveyor systems.

Advantages of Drag Chain Cable Trays

1. Protection and Organization One of the primary benefits of using drag chain cable trays is their ability to protect cables from mechanical damage and environmental factors. By keeping cables organized and secure, these trays reduce the risk of accidents and equipment failure caused by tangled wires.

2. Flexibility Drag chain systems can be adapted to various environments and applications due to their modular design. They can accommodate different cable types and sizes, making them suitable for a wide range of industrial uses.

3. Ease of Installation and Maintenance Installing drag chain cable trays is relatively straightforward, requiring minimal tools and expertise. Furthermore, their design allows for quick access to the cables, simplifying maintenance and reducing downtime.

drag chain cable tray

4. Dynamic Movement Unlike traditional cable trays, which are typically stationary, drag chain cable trays excel in applications involving movement. They are specifically designed to handle the repetitive motion of cables, such as in robotics and moving machinery, thereby prolonging the lifespan of both the tray and the cables.

5. Space Efficiency Drag chain trays can be mounted in various orientations, whether horizontally or vertically. This flexibility allows for optimal use of space in industrial setups where layout can be limited.

Applications of Drag Chain Cable Trays

Drag chain cable trays are utilized in various industries, including automotive manufacturing, aerospace, packaging, and food processing. In automotive assembly lines, for instance, these trays manage the intricate networks of cables required for robotic arms and conveyor systems. Similarly, in packaging industries, they support the continuous operation of machinery that requires constant power and communication between components.

Additionally, drag chains are crucial in the entertainment industry, where they are used to manage cables in stage production and film set equipment. By ensuring that cables remain orderly and free from tangles, these trays help prevent disruptions during live performances or filming.

Conclusion

Drag chain cable trays represent an essential solution for effective cable management in dynamic environments. Their protective qualities, flexibility, ease of installation, and ability to support movement make them indispensable in various industries. As technology continues to advance and industries evolve, the role of drag chain systems will only become more critical, contributing to enhanced safety, efficiency, and organization in the complex web of industrial wiring. Ultimately, investing in a well-designed drag chain cable tray system is a step toward achieving greater operational excellence and reliability.