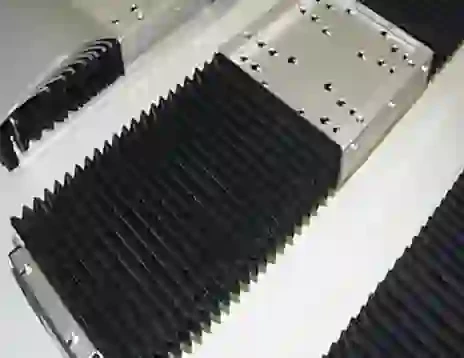

drag chain cable tray

Understanding Drag Chain Cable Trays Essential Elements for Efficient Cable Management

In industrial environments, managing cables efficiently is crucial for ensuring operational safety and maintaining equipment functionality. One of the most effective solutions for this challenge is the use of drag chain cable trays. These specialized structures provide a reliable means of organizing and protecting cables, particularly in applications where movement is a frequent occurrence.

What is a Drag Chain Cable Tray?

A drag chain cable tray, often simply referred to as a drag chain, is a type of cable management system that is specifically designed to support and protect cables in motion. They are commonly found in applications that involve robotics, automation, and manufacturing processes where machinery must continuously move along a prescribed path. Drag chains consist of a series of links connected to form a flexible channel, which allows cables and hoses to be routed safely.

Advantages of Drag Chain Cable Trays

1. Enhanced Cable Protection Drag chain cable trays provide excellent protection for cables against abrasion and environmental factors. Since they enclose the cables, they shield them from physical damage, dirt, and other contaminants that could lead to failure.

2. Easier Maintenance With cables organized neatly within the drag chain, maintenance becomes significantly easier. Technicians can quickly access individual cables without having to unbundle a tangled mess. This accessibility is essential for troubleshooting and repairs, ensuring minimal downtime.

3. Space Efficiency Drag chains are designed to be compact and efficient. They can be integrated into machinery and equipment without taking up excessive space, making them an ideal solution for environments with limited room for cable management.

4. Flexibility and Versatility Drag chain cable trays can be customized to accommodate various configurations and cable types. This versatility allows industries to tailor their cable management solutions to specific operational needs, whether it involves power cables, signal cables, or fluid hoses.

5. Reduced Wear and Tear By allowing cables to move freely while contained, drag chains minimize the wear that would typically occur from cables rubbing against each other or against sharp edges. This reduction in wear significantly extends the lifespan of cables.

Applications of Drag Chain Cable Trays

drag chain cable tray

Drag chain cable trays are widely used across various industries

. Some notable applications include- Manufacturing In automated manufacturing lines, drag chains facilitate the movement of cables attached to robotic arms, ensuring uninterrupted operation. - Construction Heavy machinery often requires a reliable cable management system to control power and signal cables that move during operations.

- Telecommunications In telecommunications infrastructure, drag chains effectively manage the multitude of cables that are necessary for robust network connectivity.

- Automotive In automotive assembly lines, drag chains allow for effective routing of cables powering robotic welding arms, painting systems, and other automated processes.

Installation and Considerations

When planning to install drag chain cable trays, several key factors should be considered

- Cable Load Assess the type and amount of cable that will be routed through the tray to ensure the correct size and load capacity for the drag chain.

- Pathway Design The layout of the drag chain should minimize bends and curves to facilitate smoother cable movement while reducing friction.

- Material Selection Different environments require different materials. For example, chains made from plastic are lighter and resistant to chemicals, while metal chains offer durability in harsh conditions.

Conclusion

Drag chain cable trays serve as a vital component in modern industrial settings, providing an efficient and effective solution for cable management in dynamic environments. By offering enhanced protection, ease of maintenance, and flexibility, they play an essential role in optimizing operational efficiency and promoting safety. As technology and industrial practices continue to evolve, the relevance and application of drag chain cable trays will likely expand, driving further innovation in cable management solutions. Investing in such systems is not only a proactive step towards ensuring operational stability but also a commitment to protecting critical infrastructure in any industrial operation.