Flexible Cable Management Solutions for Efficient Drag Chain Systems and Cable Carriers

Understanding Drag Chain Cable Carriers Essential Components for Modern Machinery

In the realm of modern industrial machinery and automation, the significance of cable management systems cannot be overstated. Among these, drag chain cable carriers have emerged as a vital component, offering solutions for the efficient organization and protection of cables and hoses in dynamic applications. This article aims to delve into the functionality, benefits, and applications of drag chain cable carriers.

What are Drag Chain Cable Carriers?

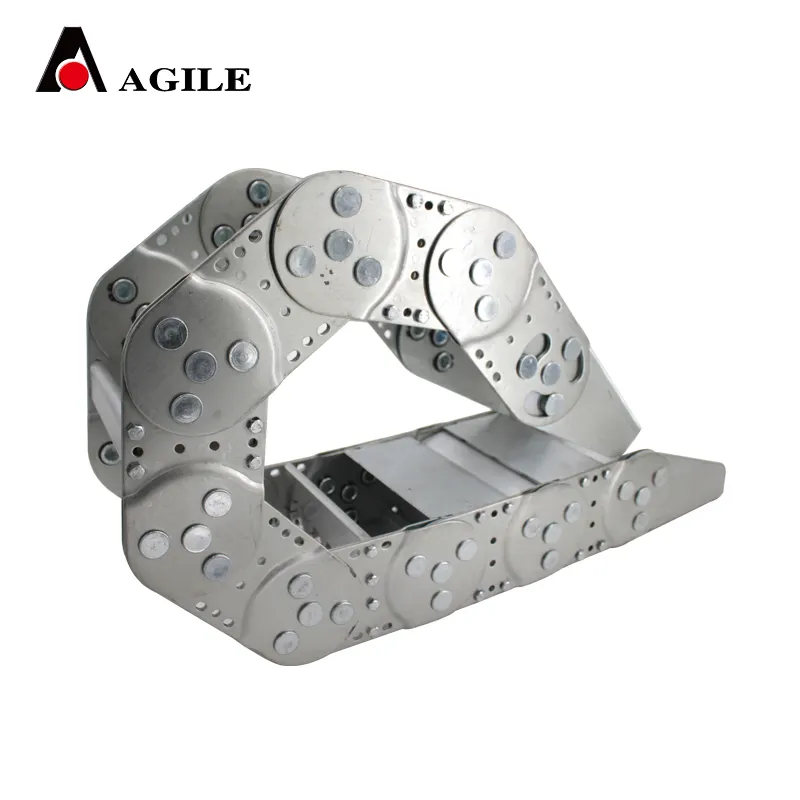

Drag chain cable carriers, also known as cable tracks or drag chains, are designed to guide and protect cables and hoses as they move with machinery. They consist of a series of interconnected links that create a channel for the cables. As machinery operates, the drag chain allows for smooth movement and prevents tangling, wearing, or damage to the cables.

The primary function of drag chains is to support and organize the cables in applications involving lateral or vertical movements, such as robotic arms, CNC machines, and conveyor systems. The design ensures that cables are kept in an orderly manner, thus enhancing the efficiency of operational processes.

Benefits of Using Drag Chain Cable Carriers

1. Protection of Cables One of the most significant advantages of drag chain cable carriers is the protection they provide. By enclosing cables within a structured channel, they shield them from abrasion, crushing, and exposure to harsh environmental conditions. This enhances the longevity of the cables and reduces maintenance costs.

2. Organization In complex machinery with multiple cables, organization is crucial. Drag chains maintain the order of cables, preventing tangling and confusion. This organization simplifies maintenance and troubleshooting, allowing for quicker repairs and reduced downtime.

drag chain cable carrier

3. Flexibility and Mobility Drag chains are incredibly flexible and can adapt to a wide range of movements. Whether it’s a linear motion or a twisting action, drag chains can accommodate various dynamic scenarios. This adaptability makes them ideal for use in a variety of machinery and applications.

4. Reduced Wear and Tear With cables properly housed in drag chains, the risk of wear and tear is significantly reduced. The controlled movement minimizes friction and contact with sharp edges, which can cause damage over time. This not only extends the lifespan of the cables but also enhances the overall reliability of the machinery.

5. Ease of Installation and Maintenance Modern drag chain systems are designed for easy installation. Many models allow for quick assembly and disassembly, making it convenient to replace cables or conduct maintenance without extensive downtime. Additionally, clear visibility of the cables facilitates easier inspections.

Applications of Drag Chain Cable Carriers

Drag chain cable carriers are widely used across various industries. One common application is in robotics, where they manage the extensive cabling required for power and control signals. In the automotive industry, drag chains are employed in automated assembly lines, ensuring that electrical connections remain intact during the movement of machinery.

Moreover, they find applications in material handling systems, machine tools, and lifting equipment. Industries such as aerospace, manufacturing, and entertainment also benefit from the versatility and reliability of drag chain cable carriers.

Conclusion

In conclusion, drag chain cable carriers are essential components in the modern industrial landscape. Their ability to protect, organize, and facilitate the movement of cables in dynamic applications makes them invaluable in promoting efficiency and reliability. As technology advances and machinery becomes increasingly sophisticated, the role of drag chains in ensuring operational integrity will only continue to grow. Investing in quality drag chain systems can lead to significant long-term benefits, ultimately enhancing productivity and reducing costs for businesses across various sectors.