drag chain 10x20

Understanding the Importance of Drag Chains A Focus on Drag Chain 10x20

In the realm of industrial machinery and equipment, drag chains have emerged as a crucial component for maintaining efficiency and organization. Among the various options available, the drag chain 10x20 stands out due to its versatility and practical design. In this article, we will explore what drag chains are, the specific attributes of the 10x20 model, their applications, and the benefits they offer in various industries.

What is a Drag Chain?

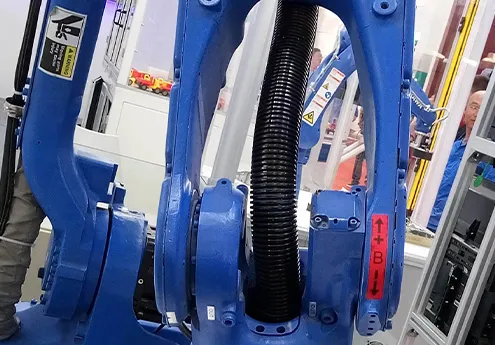

Drag chains, also known as cable carriers or cable chains, are enclosures designed to guide and protect power and control cables, hoses, and other moving components. They play a vital role in systems that involve motion, particularly in automated machinery, robotics, and CNC machines. The primary function of a drag chain is to prevent tangling, abrasion, and damage to these components as they traverse through complex movements.

The Specifications of Drag Chain 10x20

The designation 10x20 refers to the dimensions of the drag chain. Specifically, it indicates that the chain has a cross-section that is 10 mm wide and 20 mm high. This size is ideal for medium to large applications where the cables or hoses that need to be enclosed are of similar dimensions. The drag chain is typically made from durable materials such as nylon or polyurethane, which ensures long-lasting performance and resistance to wear and tear.

Applications of Drag Chain 10x20

The drag chain 10x20 can be found in various settings across multiple industries, including

1. Manufacturing In assembly lines where machinery operates continuously, drag chains help maintain organized cable management. This prevents downtime due to cable damage and reduces maintenance costs.

2. Robotics Robots often have multiple moving parts that require power and data cables. The drag chain ensures these cables are positioned safely out of harm’s way, allowing for smooth and efficient operations.

3. CNC Machines For CNC milling and turning operations, drag chains protect sensitive cables from the spinning parts and possible environmental debris that can cause short circuits or data losses.

drag chain 10x20

4. Material Handling Systems In conveyor systems, drag chains manage the electrical and pneumatic lines that control the movement of materials, ensuring seamless operation throughout the workflow.

5. Automotive and Aerospace These sectors require precise cable management for control systems, where drag chains provide the necessary support and protection for various lines within the vehicle or aircraft.

Benefits of Using Drag Chain 10x20

The drag chain 10x20 provides several benefits that enhance operational efficiency and equipment longevity

1. Protection Against Damage By encasing cables and hoses, drag chains prevent them from being crushed, pinched, or otherwise damaged—a common issue in mechanized environments.

2. Reduced Downtime A well-organized cable management system minimizes the risk of cable-related failures, which can lead to costly downtime and production delays.

3. Improved Aesthetics and Safety With cables neatly contained within a drag chain, industrial spaces appear cleaner and more organized. This not only improves safety by reducing tripping hazards but also enhances the overall work environment.

4. Flexibility and Adaptability The design of a 10x20 drag chain often allows for easy assembly and disassembly, enabling businesses to adapt to changing needs or expand their operations without excessive reconfiguration.

5. Cost-effectiveness Though there may be an initial investment in drag chains, the reduction in maintenance and downtime, along with the increased lifespan of cables and hoses, often results in significant long-term savings.

Conclusion

The drag chain 10x20 exemplifies a simple yet effective solution for managing cables and hoses in various industrial applications. Its dimensions cater to medium to large components, while its robust construction ensures durability and reliability. As businesses continue to evolve and incorporate advanced machinery, the importance of drag chains will undoubtedly grow, emphasizing their role in driving efficiency and operational success. By understanding and utilizing components like the drag chain 10x20, industries can enhance their productivity and safeguard their investments in technology.