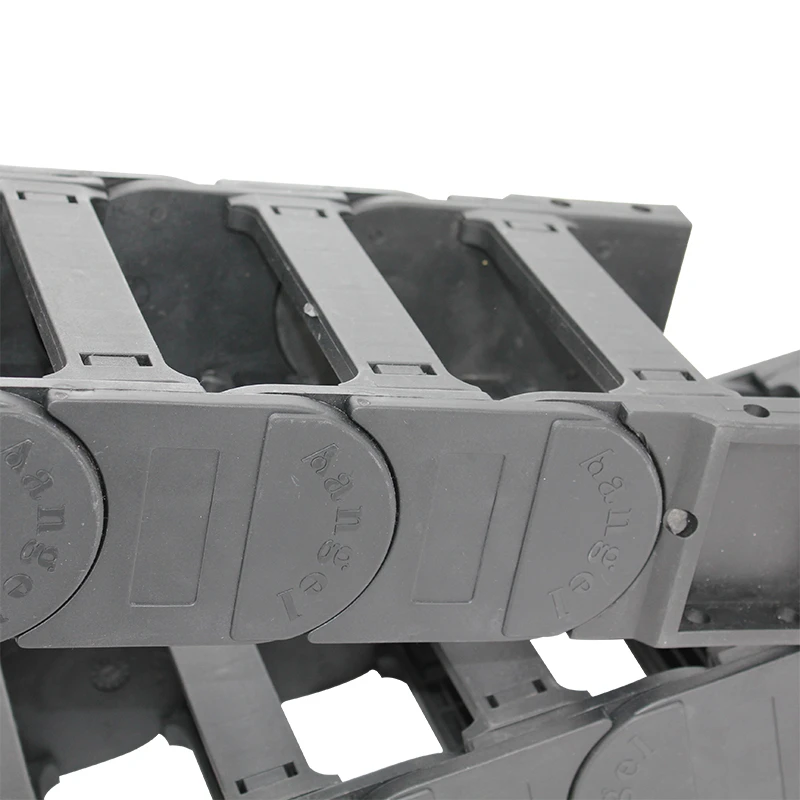

drag chain

Navigating the realm of high-performance machinery, drag chains emerge as indispensable components that ensure the smooth operation of various systems. Renowned for their ability to protect and guide cables and hoses, drag chains are critical in environments ranging from automation to heavy engineering sectors. Understanding the intricacies of their function, design, and application is central to harnessing their full potential and ensuring an optimized, reliable setup.

Drag chains, also referred to as cable carriers, excel in protecting moving cables from wear and mechanical stress. Derived from robust materials like steel and engineered plastics, they are designed to withstand harsh environmental conditions. This durability ensures that systems function seamlessly, free from interruptions caused by cable entanglement or deterioration.

One of the key applications of drag chains is in CNC machinery, where precision and reliability are paramount. In this context, drag chains are tasked with moving cables and hoses in synchronized harmony, preventing interference with moving parts and guarding against wear and tear. Their flexibility and strength contribute significantly to the longevity of the machinery, saving costs on maintenance and downtime. An expert in CNC setup will attest to the pivotal role drag chains play in maintaining the integrity of machine operations.

Specialists in the field of robotics also extol the virtues of drag chains. With the precision that robotics demands, the consistent and dependable function of drag chains ensures that control systems remain uninterrupted. They support the dynamic movements of robotic arms, providing a stable conduit for an array of wires and cables. The expertise required to integrate these into robotic systems speaks to their complexity and essential role in advanced technology environments.

What sets drag chains apart is their adaptability. They can be customized to specific lengths and configurations to suit the individualized needs of different machines or systems. This customization is essential in environments where space is limited or unique movements are required. Engineers with deep experience in system design often emphasize the importance of selecting the right type and configuration of drag chains to match the specific operational demands.

drag chain

In the energy sector, especially within wind and solar power plants, drag chains are critical components. Here, they are used to manage the extensive cabling required in turbines and solar panels. Their ability to operate under continuous stress, along with resistance to environmental factors like UV exposure and temperature fluctuations, highlights their reliability. Specialists in sustainable energy system design often rely on the proven dependability of drag chains to optimize performance and efficiency.

From an authoritative standpoint, manufacturers of drag chains are continuously innovating, utilizing cutting-edge materials and designs to enhance performance parameters. Certification by recognized industry bodies adds a layer of trustworthiness, ensuring users that these products meet stringent quality and safety standards. This endorsement is particularly important for industries where failure can result in significant financial or operational repercussions.

Trusted by engineers across disciplines, drag chains are not just components, but integral systems that enhance the durability and efficiency of diverse applications. As technology continues to advance, the reliance on such components underscores their authority within technical circles. A reputable authority on mechanical components would note the immense contribution drag chains have made to industrial progress, marking them as elements that any professional serious about performance optimization should understand and implement.

In conclusion, for those seeking to maximize the reliability and efficiency of their machinery, a well-designed drag chain system is indispensable. Its role in protecting vital cables and hoses cannot be overstated. Leveraging the combined expertise and experience of industry professionals, drag chains are established as trusted solutions within the mechanical domain. Their continued innovation will likely spur new applications, aligning with future technological advancements and maintaining their authoritative position in the industrial landscape.