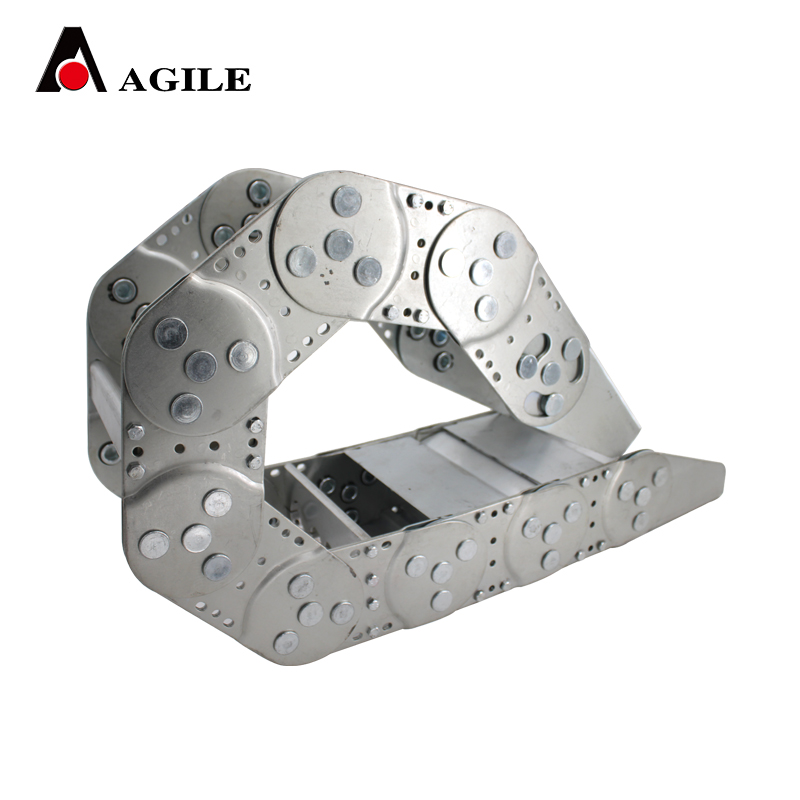

drag cables

The Importance of Drag Cables in Modern Engineering

Drag cables play a crucial role in various engineering applications, particularly in the fields of robotics, construction, and automation. These cables are designed to manage the movement of electrical and data connections between stationary and moving parts of machinery. As industries continue to advance technologically, the importance of drag cables becomes increasingly apparent, aiding in the efficiency and reliability of mechanical operations.

One of the most significant advantages of drag cables is their ability to reduce wear and tear on electrical connections. In many industrial applications, machines need to move dynamically—pivoting, extending, or retracting as required by different tasks. Without drag cables, traditional wiring would be subject to excessive strain, leading to premature failure or interruptions in service. Drag cables are built to withstand these movements dynamically, ensuring that vital connections remain intact and functional.

Moreover, drag cables contribute to improved safety standards in workplaces

. In environments where heavy machinery is in constant motion, entangled cables pose a serious hazard. Drag cables, often enclosed in a protective sheath, are designed to keep wiring organized and out of harm's way, significantly reducing the risk of accidents. This organized setup not only enhances safety but also makes troubleshooting and maintenance more straightforward, allowing engineers to quickly identify and address issues without disrupting operations.drag cables

In addition to their practical applications, drag cables are essential for data transmission in modern automated systems. As industries increasingly rely on real-time data for making critical decisions, maintaining a reliable data connection is paramount. Drag cables can support a range of signals, including power, data, and control functions, all in a single, streamlined package. This versatility is particularly vital in robotics, where precision and reliability in data communication can significantly impact operational effectiveness.

The design and materials used in drag cables are continually evolving, driven by the need for greater flexibility, durability, and efficiency. Advances in materials science have led to the development of lighter and more robust cables that can better handle adverse environmental conditions, such as extreme temperatures or exposure to chemicals. This ensures that drag cables can meet the increasing demands of modern applications and maintain their integrity over time.

Furthermore, as the trend towards automation and smart technology grows, the role of drag cables is becoming even more pivotal. Industries are embracing more compact and integrated solutions that require sophisticated cabling systems. Drag cables are instrumental in these setups, allowing for greater freedom of movement while ensuring connectivity remains seamless.

In conclusion, drag cables represent a vital component in the machinery and automation landscape. Their ability to facilitate movement, enhance safety, and support data integrity makes them indispensable in modern engineering practices. As technology continues to advance, the evolution of drag cables will undoubtedly play a significant role in shaping the future of industrial operations. Embracing and understanding the functionality of drag cables will assist companies in maximizing efficiency and ensuring the longevity of their equipment.