Drag Chain Conveyor - Efficient Material Handling Solutions

Understanding Drag Chain Conveyors An Overview

In the realm of material handling systems, drag chain conveyors play a crucial role. These conveyors are designed to move bulk materials efficiently and are utilized in various industries, including agriculture, mining, and food processing. Understanding the operation, advantages, and applications of drag chain conveyors is essential for businesses looking to enhance their material handling processes.

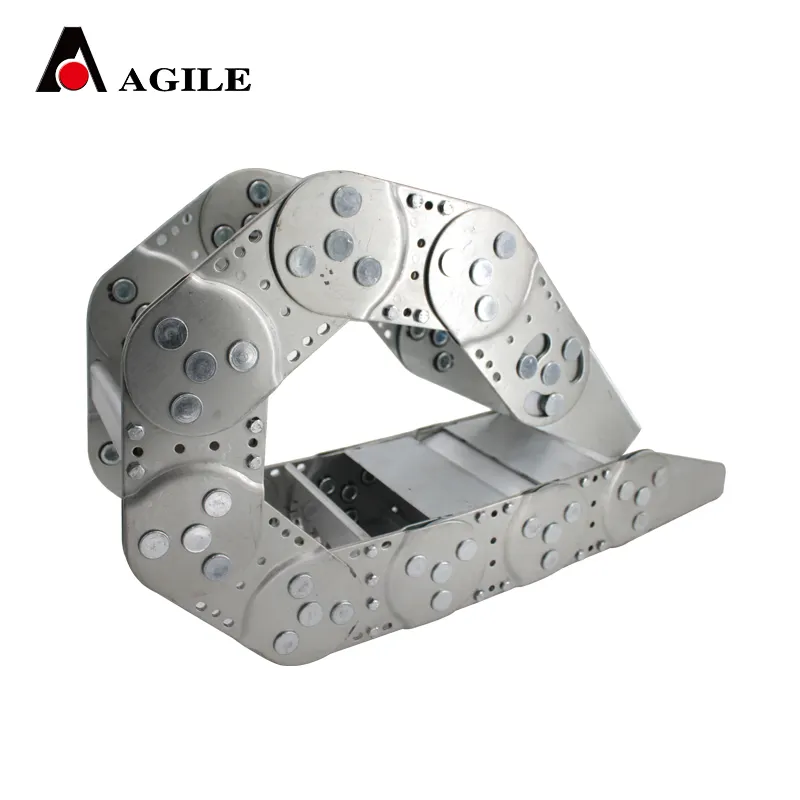

At its core, a drag chain conveyor consists of a series of linked chains that run along a track. These chains are equipped with flights or scrapers that help transport materials along the system. The conveyor operates within a trough or channel, providing a sturdy and reliable pathway for bulk materials to be moved from one point to another. A typical setup involves a drive unit at one end of the conveyor, which powers the chains and propels the materials forward.

One of the defining features of drag chain conveyors is their ability to handle a wide variety of materials. They are particularly suited for the transport of bulk solids, including grains, powders, and aggregates. The enclosed design of these conveyors minimizes dust generation and spillage, making them an ideal choice for industries where cleanliness is paramount. Furthermore, the robust construction allows them to manage heavy loads, making them suitable for demanding applications.

The efficiency of drag chain conveyors lies in their continuous operation. Unlike other conveyor systems that may require frequent stoppages or adjustments, drag chain conveyors can operate seamlessly for extended periods. This continuous operation reduces downtime, thereby increasing productivity. Additionally, they can be configured to navigate complex pathways, including inclines, declines, and transfers, which can be pivotal in optimizing space within a facility.

drag chain conveyor

Another significant advantage of drag chain conveyors is their low maintenance requirements. With fewer moving parts compared to other conveyor systems, drag chain conveyors tend to have a longer lifespan and reduced need for repairs. Regular maintenance focuses primarily on lubrication and occasional adjustments, making it easier for facility managers to maintain operational efficiency.

Moreover, the adaptability of drag chain conveyors is noteworthy. They can be designed for different speeds and capacities depending on the specific needs of the application. This flexibility enables businesses to customize their material handling systems, ensuring they can meet specific operational demands without significant modifications to existing infrastructure.

In terms of safety, drag chain conveyors are designed with various features to protect operators and machinery. Enclosed systems reduce the likelihood of accidents caused by falling materials or unexpected equipment movements. Additionally, the ability to control the speed and motion of the conveyor minimizes risks associated with material handling.

In conclusion, drag chain conveyors offer a robust, efficient, and adaptable solution for bulk material handling. Their ability to handle a wide range of materials, coupled with low maintenance needs and enhanced safety features, makes them a valuable asset in various industries. As businesses continue to seek ways to improve operational efficiency and reduce costs, the use of drag chain conveyors will likely remain a popular choice for material handling solutions. Investing in these systems not only streamlines operations but also positions companies for greater success in the competitive market landscape.