Drag Chain Cable Carrier - Durable Solutions for Cable Management

Understanding Drag Chain Cable Carriers An Essential Component in Modern Machinery

Drag chain cable carriers, also known as cable drag chains or cable carriers, play a crucial role in the field of automation and machinery. These innovative devices are designed to protect and manage cables and hoses in various applications, ensuring that they operate safely and efficiently. Typically used in industrial settings such as manufacturing plants, robotics, and CNC machines, drag chain cable carriers have become indispensable due to their ability to enhance mobility and reduce wear.

What is a Drag Chain Cable Carrier?

A drag chain cable carrier is a modular system that consists of linked segments forming a flexible enclosure. This enclosure houses various cables, hoses, and wires, allowing them to move freely while preventing tangling and abrasion. As machinery operates or moves, the drag chain facilitates the smooth travel of these essential components, minimizing the risk of damage from friction or strain.

Benefits of Using Drag Chain Cable Carriers

One of the primary benefits of drag chain cable carriers is their protective nature. By enclosing cables and hoses, they shield them from environmental factors such as dust, dirt, and moisture, which can lead to premature wear or electrical failures. Furthermore, the streamlined organization ensures that cables do not become entangled, hence reducing downtime associated with maintenance and repairs.

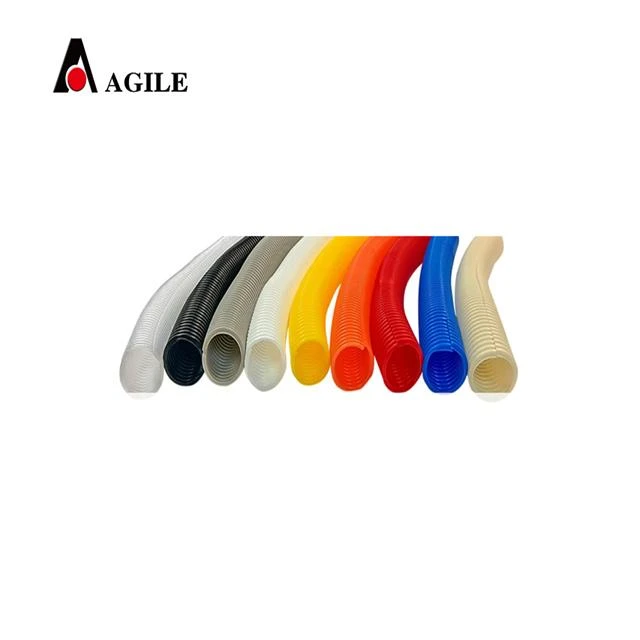

drag chain cable carrier

Another significant advantage is the increased flexibility they provide. Drag chain cable carriers come in various sizes and configurations, making them adaptable to different environments and machinery types. They can manage multiple cables simultaneously, providing an efficient solution for complex setups. This adaptability also allows for easy installation and reconfiguration as machinery evolves or relocates.

Applications Across Industries

Drag chain cable carriers are widely utilized across various industries due to their versatility. In manufacturing, they are essential for powering equipment like conveyor belts, robotic arms, and assembly lines. In the aerospace sector, they help manage wiring in aircraft systems, ensuring reliability and safety during flight. Similarly, in the automotive industry, these carriers support robotic welding and assembly operations, improving production speed and precision.

Conclusion

In conclusion, drag chain cable carriers are vital components in modern machinery, offering protection, organization, and flexibility for cables and hoses. Their ability to enhance operational efficiency while reducing wear makes them an essential investment for businesses looking to optimize their processes. As technology continues to advance, the importance of these carriers will only grow, paving the way for safer and more efficient manufacturing environments. Understanding their functionality and applications is key for any industry that relies heavily on automated machinery.