Design and Functionality of Telescopic Bellow Covers for Industrial Applications

Telescopic Bellow Covers A Comprehensive Overview

Telescopic bellow covers, often referred to as bellows, are crucial components in various industrial applications, particularly in machine tools and manufacturing environments. These protective covers are designed to shield moving parts from dirt, debris, and other environmental factors while facilitating smooth movement and operation. This article delves into the significance, construction, benefits, and applications of telescopic bellow covers, showcasing their essential role in modern machining processes.

Understanding Telescopic Bellow Covers

Telescopic bellow covers are composed of flexible materials, usually rubber, plastic, or fabric, which allow them to expand and contract as machinery operates. The design mimics an accordion or bellows shape, enabling them to accommodate the movement of sliding or rotating components. Their primary purpose is to protect sensitive machine parts, such as leadscrews, guides, and spindles, from contaminants that could cause wear, corrosion, or malfunction.

Construction and Materials

The construction of telescopic bellow covers typically involves multiple layers to enhance durability and functionality. The outer layer is often crafted from a robust material resistant to abrasion and chemicals, while the inner lining may provide additional cushioning against impact. The bellows are designed to be flexible yet sturdy, allowing for extensive movement without compromising their protective capabilities.

Common materials used in the production of telescopic bellow covers include

1. Rubber Offers excellent flexibility and resistance to harsh environments. 2. Polyurethane Known for its durability and resistance to abrasion and tearing. 3. PVC (Polyvinyl Chloride) Lightweight and cost-effective, suitable for less demanding applications. 4. Fabric composites Often used for specialized applications requiring high levels of flexibility and strength.

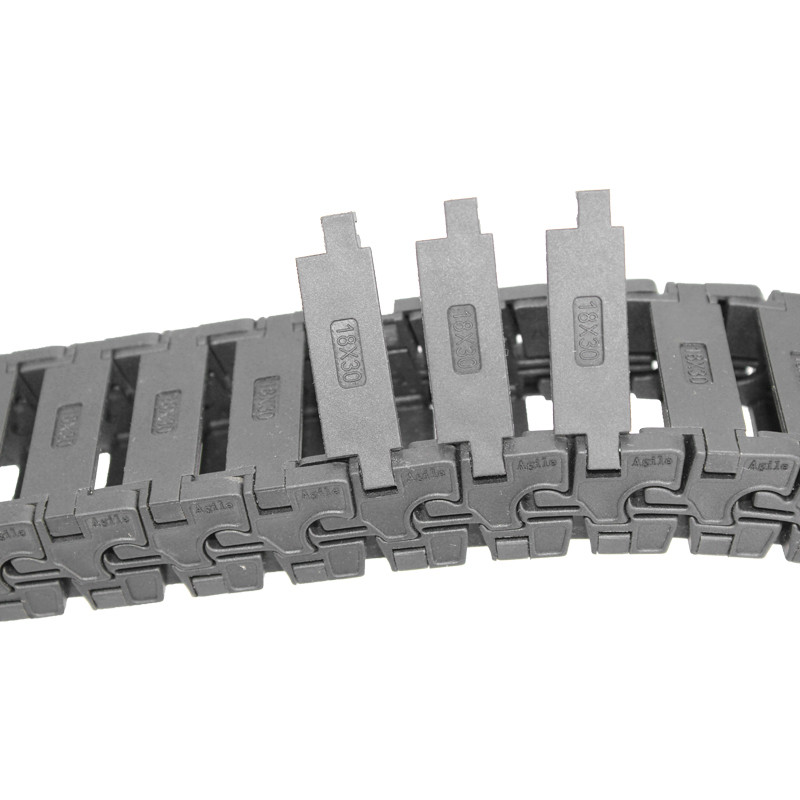

telescopic bellow cover

Benefits of Telescopic Bellow Covers

The advantages of using telescopic bellow covers are numerous

1. Protection against contamination The primary function of bellows is to protect machinery from dust, dirt, chips, and other contaminants, thereby prolonging the lifespan of equipment. 2. Reduction of maintenance costs By preventing the ingress of harmful materials, telescopic bellows reduce wear and tear on machine components, leading to lower maintenance costs and fewer downtime incidents. 3. Improved safety Bellows enhance the safety of workplace environments by preventing entanglement and reducing the risk of accidents caused by exposed machinery. 4. Versatility Telescopic bellows can be tailored to fit a wide range of machinery and applications, from CNC machines to robotics, making them a versatile choice across industries.

Applications in Various Industries

Telescopic bellow covers find applications in numerous industries, including

1. Manufacturing In CNC machines, milling machines, and lathes, bellows protect the linear guides and ball screws from debris and liquids. 2. Robotics Bellows offer protection for moving robotic arms, ensuring smooth operation and longevity. 3. Printing In printing machines, telescopic bellows keep ink and dust away from sensitive components, enhancing print quality. 4. Automotive Bellows are used in various automotive applications, including protecting hydraulic cylinders and steering components from contaminants.

Conclusion

In conclusion, telescopic bellow covers are an indispensable element in modern industrial machinery, offering protection, versatility, and cost savings. Their innovative design and robust materials provide essential safeguarding against contaminants, thus enhancing operational efficiency and equipment longevity. As industries continue to evolve, the role of telescopic bellow covers will undoubtedly remain pivotal in ensuring the smooth and safe functioning of machinery across various applications. Investing in quality bellows is not just a matter of protection; it’s a commitment to efficiency, safety, and sustainability in the manufacturing landscape.