Design and Application of Metal Bellows Covers for Enhanced Protection and Performance in Machinery

The Importance of Metal Bellow Covers An Overview

In various industrial applications, safeguarding equipment and enhancing longevity is paramount. Among the many protective solutions available, metal bellow covers have emerged as a vital component in machinery and equipment design. This article explores the benefits, applications, and importance of metal bellow covers in providing reliable protection against environmental factors.

What Are Metal Bellow Covers?

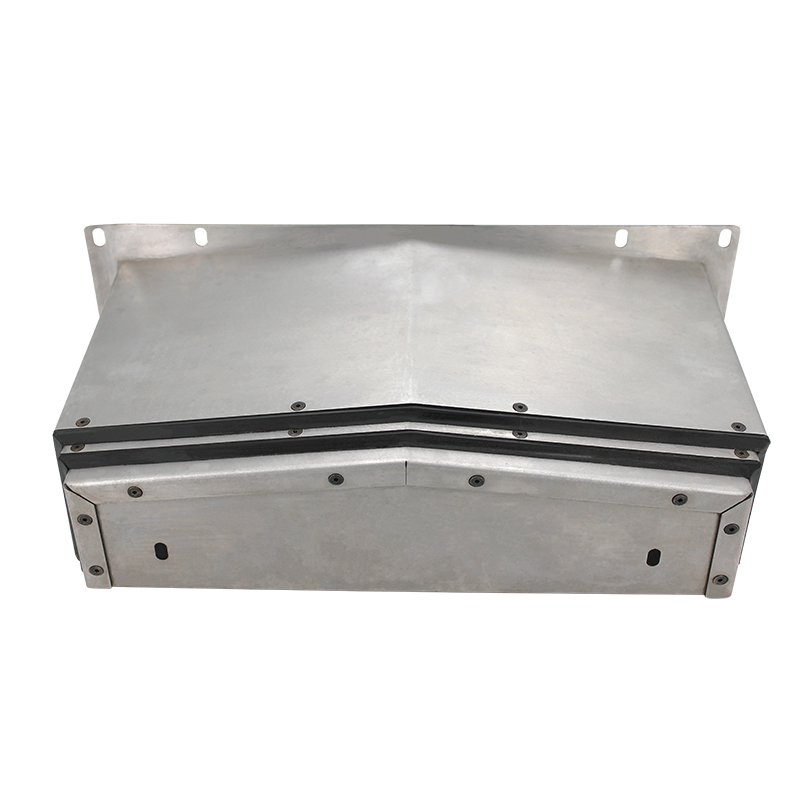

Metal bellow covers are flexible, accordion-like structures made from durable metals, such as stainless steel or carbon steel. They are designed to cover and protect moving parts of machinery, particularly those that experience linear motion, such as leadscrews, spindles, and pistons. These covers can accommodate significant movements while maintaining their shape, thus preventing the ingress of contaminants like dust, dirt, and moisture.

Benefits of Metal Bellow Covers

1. Protection from Contaminants One of the primary functions of metal bellow covers is to shield vulnerable components from harmful environmental factors. By preventing the penetration of dust, debris, and moisture, these covers help maintain the operational efficiency of the machinery and reduce the risk of wear and tear.

2. Durability and Longevity Metal bellow covers are known for their robustness and resistance to wear. Unlike fabric covers, which can degrade over time, metal covers can withstand high temperatures and harsh environments, ensuring that they provide long-term protection for equipment.

metal bellow cover

3. Flexibility The design of metal bellow covers allows for significant movement without losing their protective capabilities. This flexibility is essential for applications where components are subject to frequent or rapid movement, as it ensures consistent protection and minimizes the risk of malfunction.

4. Cost-Effectiveness Investing in metal bellow covers can lead to significant cost savings over time. By protecting machinery components, these covers can reduce maintenance costs, extend equipment life, and decrease downtime due to repairs or replacements.

Applications of Metal Bellow Covers

Metal bellow covers are used across a range of industries, including manufacturing, aerospace, automotive, and robotics. In manufacturing, they protect CNC machines, mills, and lathes from dust and chips that can impair functionality. In the aerospace sector, they safeguard hydraulic and pneumatic systems from environmental wear, thus ensuring optimal performance.

Additionally, metal bellow covers are increasingly being utilized in robotic systems, where precision and cleanliness are critical. Their ability to shield sensitive components without hindering motion makes them ideal for robotic arms and other automated machinery.

Conclusion

In conclusion, metal bellow covers play a crucial role in protecting machinery and enhancing durability across various industries. Their ability to guard against contaminants, coupled with their flexibility and longevity, makes them an essential component of modern mechanical design. As industries continue to evolve and strive for higher efficiency and reliability, the use of metal bellow covers will likely become even more prevalent. Investing in these protective solutions not only enhances the performance of equipment but also supports a more sustainable and cost-effective operational approach in the long run.