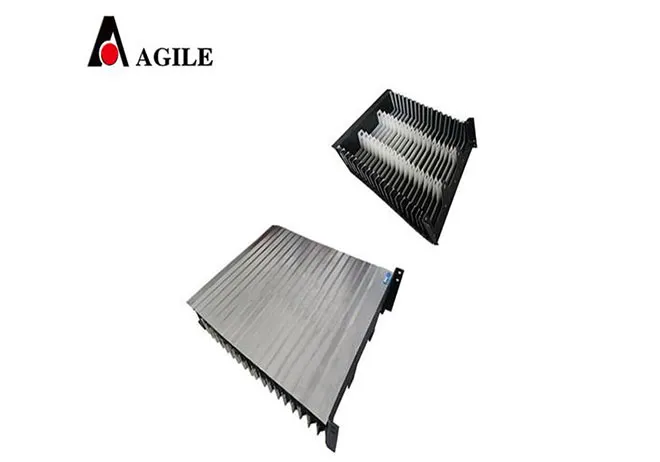

cylinder bellow cover

The Significance of Cylinder Below Cover in Modern Engineering

In the realm of engineering and manufacturing, precision and safety are paramount. One critical component that embodies these principles is the cylinder below cover. Often overlooked, the cylinder below cover plays a vital role in various applications, especially in hydraulic systems and machinery. This article delves into its importance, design considerations, and the advancements that have enhanced its functionality.

Understanding the Cylinder Below Cover

The cylinder below cover refers to the protective casing or housing that encloses hydraulic cylinders. Its primary function is to provide a barrier that safeguards the internal components of the cylinder from external contaminants such as dirt, moisture, and debris. Additionally, it helps maintain hydraulic pressure by preventing fluid leakage, which is crucial for the efficient operation of hydraulic systems.

In many applications, the durability and integrity of hydraulic systems are directly influenced by the effective sealing properties of the cylinder below cover. A compromised cover can lead to fluid loss, resulting in decreased performance, increased wear, and potential system failure. Therefore, it is imperative that engineers pay close attention to the design and material selection of these covers.

Design Considerations

When designing a cylinder below cover, several factors must be taken into account

1. Material Selection The choice of material is critical, as it must withstand varying pressures, temperatures, and environmental conditions. Common materials include high-strength metals, composites, and robust plastics, each offering unique advantages in terms of weight, cost, and resistance to corrosion.

2. Sealing Mechanisms Effective sealing is essential for preventing leaks. Engineers often employ O-rings, gaskets, or custom sealing solutions to ensure a tight fit. The design must accommodate the necessary sealing features while allowing for easy maintenance and replacement.

3. Heat Dissipation In many hydraulic applications, excessive heat can build up within the cylinder. The design of the below cover should facilitate heat dissipation to protect the internal components. This can be achieved through the incorporation of cooling fins or ventilation features.

cylinder bellow cover

4. Shock Resistance The cylinder below cover must be engineered to withstand mechanical shocks and vibrations, which are common in dynamic operating environments. Reinforced structures can help absorb and distribute these forces, protecting the cylinder's integrity.

5. Manufacturability Lastly, the design should consider manufacturability and cost-effectiveness. Advances in manufacturing techniques, such as additive manufacturing and CNC machining, allow for intricate designs that can be produced efficiently.

Advancements in Technology

Recent advancements in technology have significantly improved the design and functionality of cylinder below covers. For instance, the integration of smart sensors into the covers enables real-time monitoring of pressure, temperature, and seal integrity. These sensors can alert operators to potential issues before they escalate, thereby minimizing downtime and maintenance costs.

Moreover, innovations in materials science have led to the development of advanced composites that offer superior performance characteristics compared to traditional materials. These new materials are not only lighter but also possess enhanced resistance to wear and corrosion, extending the operational lifespan of the hydraulic systems they protect.

Another noteworthy trend is the growing emphasis on sustainability in engineering practices. As industries transition towards more eco-friendly operations, the fabrication of cylinder below covers is evolving. Manufacturers are exploring recyclable materials and sustainable production methods to minimize environmental impact.

Conclusion

In conclusion, while often taken for granted, the cylinder below cover is a critical component in the realm of hydraulic systems and machinery. Its role in maintaining the integrity and efficiency of hydraulic cylinders cannot be overstated. Engineers must prioritize thoughtful design, innovative materials, and emerging technologies to optimize the performance of these covers.

As industries continue to advance, the role of cylinder below covers will only become more significant. By focusing on durability, effectiveness, and sustainability, engineers can ensure that hydraulic systems operate seamlessly, safely, and efficiently, ultimately driving progress across various sectors. The future of engineering will rely on the continuous improvement of even the smallest components, demonstrating that every detail counts in the pursuit of excellence.