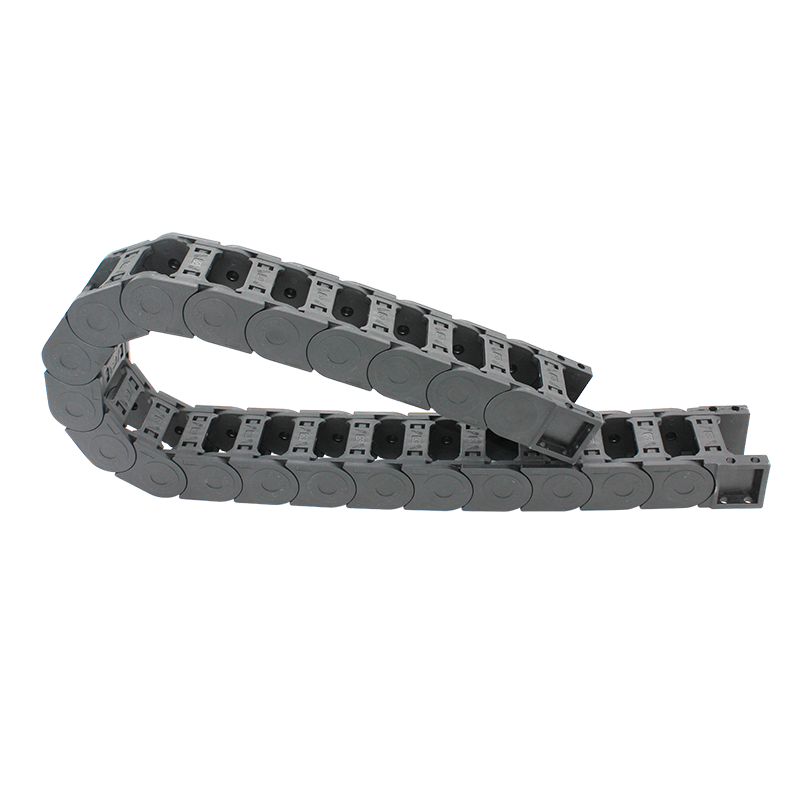

corrugated wire loom tubing

Understanding Corrugated Wire Loom Tubing Benefits and Applications

Corrugated wire loom tubing is an essential component in various industries, serving as a reliable solution for protecting and organizing wiring systems. This versatile tubing, typically made from polyethylene or polyvinyl chloride (PVC), features a helical structure that allows for flexibility, ease of installation, and excellent durability. In this article, we will delve into the features, benefits, applications, and installation methods of corrugated wire loom tubing.

What is Corrugated Wire Loom Tubing?

Corrugated wire loom tubing is designed to encase and protect electrical wires and cables. Its corrugated design provides a significant degree of flexibility, allowing it to accommodate various wire sizes and configurations. The tubing is available in multiple diameters, making it suitable for a wide range of applications, from automotive wiring to industrial machinery.

Key Features

1. Flexibility The corrugated structure allows the tubing to bend and twist without compromising its integrity. This flexibility is vital in complex installations where wires must navigate around corners and obstacles.

2. Durability Made from sturdy materials such as polyethylene or PVC, wire loom tubing is resistant to abrasions, chemicals, and environmental stressors. This durability ensures that it can withstand harsh working conditions, making it ideal for both indoor and outdoor applications.

3. Lightweight Despite its strength, corrugated wire loom tubing is lightweight, making it easy to handle and install. This characteristic is particularly beneficial in applications where reducing overall weight is a priority, such as in automotive design.

4. Customizable The tubing can be cut to specific lengths, allowing for tailored solutions that perfectly fit the application. Additionally, it can be produced in various colors, enhancing organization and identification of different wire systems.

Benefits of Using Corrugated Wire Loom Tubing

1. Protection from Damage One of the primary functions of wire loom tubing is to shield wires from physical damage. The corrugated surface helps absorb impact, preventing fraying or breaking of wire insulation, which could lead to electrical shorts or failures.

2. Organized Wiring By grouping multiple wires together, corrugated tubing helps maintain a tidy workspace, reducing clutter and making troubleshooting or modifications easier.

corrugated wire loom tubing

4. Heat and Chemical Resistance Many types of corrugated wire loom tubing are designed to withstand extreme temperatures and exposure to various chemicals, making them suitable for automotive, industrial, and outdoor applications.

5. Cost-Effective Given its durability and protective qualities, investing in corrugated wire loom tubing can be more economical over time as it reduces the need for frequent wire replacements and repairs.

Applications

Corrugated wire loom tubing is widely employed across numerous industries

1. Automotive In vehicles, the tubing protects wiring systems from engine heat, vibrations, and harsh conditions, ensuring reliable performance.

2. Industrial Machinery Manufacturing plants and industrial settings utilize this tubing to protect and organize complex wiring systems within heavy machinery.

3. Home Appliances Many electrical appliances use corrugated wire loom tubing to safeguard internal wiring, enhancing safety and longevity.

4. Electronics In consumer electronics, the tubing is often employed to create a neat and organized appearance while protecting sensitive wiring.

5. Marine Applications Boats and other marine vehicles use this tubing for its resistance to coastal environments, protecting wiring from saltwater and other corrosive elements.

Installation

Installing corrugated wire loom tubing is straightforward. The process begins with measuring the required length of tubing and cutting it accordingly. Once cut, the wires should be grouped together and inserted into the tubing. In some cases, additional tools such as cable ties or clamps may be used to secure the tubing in place, ensuring that it does not shift during operation.

Conclusion

Corrugated wire loom tubing is a vital component for anyone dealing with electrical wiring. Its combination of flexibility, durability, and protection not only enhances the performance and longevity of wiring systems but also contributes to safety and organization in various applications. By understanding its features and benefits, users can make informed decisions in protecting their wiring systems effectively. Whether in automotive, industrial, or consumer applications, corrugated wire loom tubing proves to be an invaluable asset in electrical design and maintenance.