Flexible and Durable Solutions with Corrugated Wire Loom for Cable Management

The Importance of Corrugated Wire Loom in Modern Applications

In today's world, the significance of effective cable management cannot be overstated. With technology permeating every aspect of our lives, the need for organized and protected wiring systems is more critical than ever. Enter the corrugated wire loom, a versatile solution that streamlines wire organization while providing essential protection against environmental hazards.

What is Corrugated Wire Loom?

Corrugated wire loom is a tubular conduit made from high-density polyethylene (HDPE) or other robust materials, featuring a corrugated design that offers flexibility and durability. This unique structure allows it to adapt to various shapes and configurations, making it an excellent choice for protecting and organizing wires and cables in a multitude of applications. The corrugation enhances the loom's resistance to pressure and wear, ensuring the wires it houses remain safe from abrasions, cuts, and environmental factors.

Advantages of Using Corrugated Wire Loom

1. Protection One of the primary benefits of corrugated wire loom is its ability to shield cables from physical damage and environmental stressors. Whether it’s exposure to moisture, UV radiation, or chemicals, the robust design of the loom offers a protective barrier, enhancing the lifespan and reliability of the wiring systems.

2. Flexibility and Versatility The flexibility of corrugated wire loom allows it to bend and curve to fit around corners and obstacles, making it ideal for complex installations. This adaptability is particularly beneficial in automotive, industrial, and construction applications, where wires often navigate tight spaces and intricate paths.

3. Organization In many settings, disorganized cables can lead to inefficiencies and safety hazards. Corrugated wire loom provides a systematic way to manage and route wires, reducing clutter and making maintenance easier. By keeping wires contained, it helps prevent entanglement and simplifies troubleshooting and repairs.

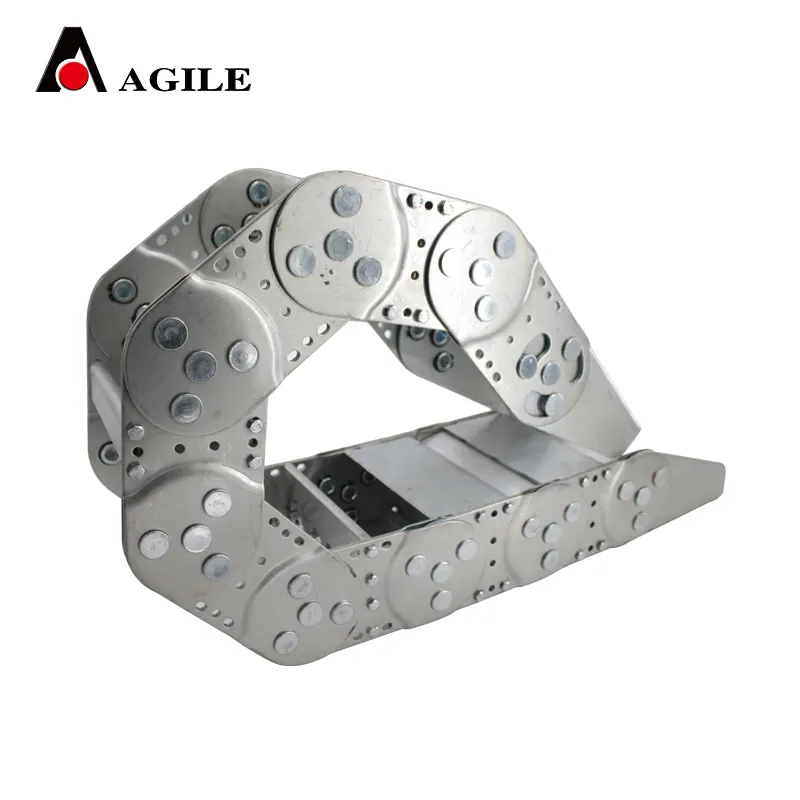

corrugated wire loom

4. Cost-Effective Solution Utilizing corrugated wire loom can be a cost-effective choice for businesses and individuals. By prolonging the life of cables through protection and reducing the risk of damage, users can save money on repairs and replacements. Furthermore, the ease of installation minimizes labor costs in various setups.

5. Aesthetic Appeal In environments where aesthetics matter, such as offices or homes, wire organization becomes crucial. Corrugated wire loom allows for a tidy appearance, concealing messy wiring while maintaining accessibility for future adjustments.

Applications of Corrugated Wire Loom

The applications of corrugated wire loom are extensive and diverse. In the automotive industry, it is commonly used to protect wiring harnesses from heat and abrasion, ensuring consistent performance. In the realm of electronics, it serves to safeguard wires in devices and appliances, contributing to both safety and functionality.

Industrially, corrugated wire loom is instrumental in factory settings where machinery and equipment require orderly wiring for optimal operations. Moreover, in construction, it plays a critical role in protecting cables from construction debris and environmental elements during the building process.

Conclusion

In summary, corrugated wire loom is an invaluable tool in the realm of cable management and protection. Its combination of durability, flexibility, and organizational benefits makes it an essential component in various industries, from automotive to construction. As technology continues to advance, the importance of maintaining secure and efficient wiring systems will only grow, making the corrugated wire loom a staple in modern applications. By investing in quality wire management solutions like corrugated wire loom, users can enhance safety, efficiency, and longevity in their wiring systems, paving the way for a more organized and reliable technological future.