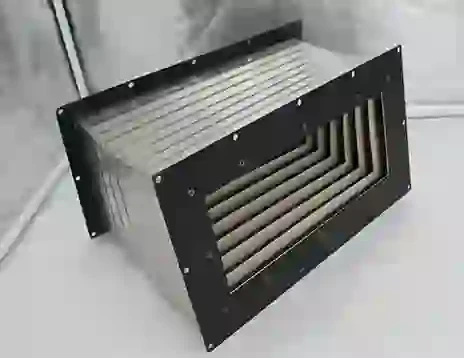

corrugated wire loom

The Versatility and Importance of Corrugated Wire Looms

In today's fast-paced technological world, the management of electrical wiring has become increasingly critical for the safety, efficiency, and organization of various systems. One vital component that has gained prominence in this regard is the corrugated wire loom. This innovative product is designed to protect and organize wires, cables, and hoses across a myriad of applications, spanning from automotive industries to industrial machinery and home use.

What is a Corrugated Wire Loom?

A corrugated wire loom is a flexible tubing made from durable materials like polyethylene, which features a ribbed structure. This corrugated design allows the loom to easily bend and twist, accommodating a variety of cable configurations and complex routing paths. The primary purpose of the corrugated wire loom is to safeguard wires from physical damage, abrasion, and environmental factors while also providing a neat and organized appearance.

Key Advantages of Using Corrugated Wire Looms

1. Protection from Damage One of the most significant advantages of corrugated wire looms is their ability to protect wires from mechanical wear and tear. In environments where abrasion is a concern, such as automotive or industrial settings, the protective layer offered by corrugated looms can significantly extend the lifespan of wiring.

2. Organizational Benefits Aesthetics and organization play critical roles in any electrical installation. Corrugated wire looms help bundle wires together, preventing tangling and confusion. This not only improves the overall appearance of the installation but also simplifies troubleshooting and maintenance by allowing for easier identification of individual wires.

3. Ease of Installation Thanks to their flexible nature, corrugated wire looms are easy to install. They can be cut to the desired length and fitted over existing wiring without complicated tools. This simplicity is especially beneficial in tight spaces or complex routing scenarios.

corrugated wire loom

4. Resistance to Environmental Factors Many corrugated wire looms are designed to resist chemicals, UV rays, and extreme temperatures. This resistance makes them ideal for outdoor applications and in environments where exposure to harsh conditions is inevitable.

5. Variety of Sizes and Colors Corrugated wire looms are available in various diameters and colors, allowing users to choose the most suitable options for their specific needs. This variety enables better organization and can even aid in complying with color-coding standards in electrical systems.

Applications of Corrugated Wire Looms

Corrugated wire looms find applications in a wide range of industries. In the automotive sector, they are used to protect wiring harnesses from damage caused by vibrations and environmental factors. In the aerospace industry, where weight and space are critical, they help organize and protect wiring without adding unnecessary bulk.

In home appliances and consumer electronics, corrugated wire looms ensure that power cords and internal wiring are safely contained, reducing the risk of electrical hazards. Moreover, in industrial settings, they play a pivotal role in cable management systems, ensuring that electrical systems operate efficiently and safely.

Conclusion

As the demand for organized and secured wiring continues to rise, corrugated wire looms stand out as an essential component in achieving these goals. Their protective features, ease of use, and adaptability make them invaluable in a variety of applications, enhancing not only the functionality but also the safety of electrical systems. Whether in automotive, industrial, or residential settings, the corrugated wire loom is a simple yet highly effective solution to modern wiring challenges. As technology evolves, the importance of such protective measures will undoubtedly continue to grow, solidifying the corrugated wire loom's position as a staple in electrical management practices.