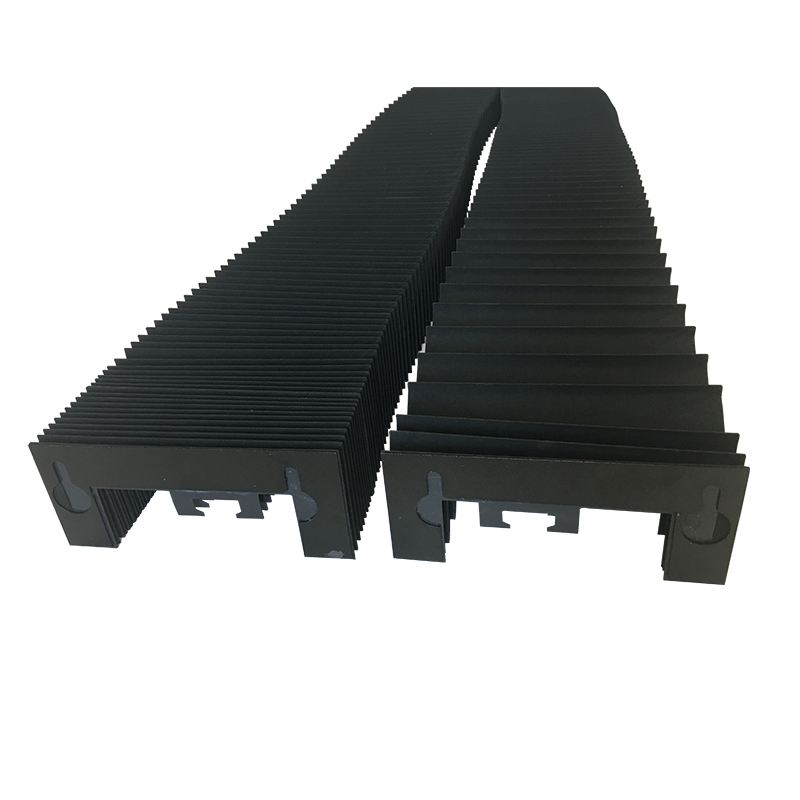

corrugated split loom tubing

Understanding Corrugated Split Loom Tubing A Comprehensive Guide

In the world of electrical and mechanical applications, ensuring the safety and integrity of wiring and cables is paramount. One component that plays an essential role in this regard is corrugated split loom tubing. This article will delve into what corrugated split loom tubing is, its benefits, applications, and how to use it effectively.

What is Corrugated Split Loom Tubing?

Corrugated split loom tubing is a protective plastic covering designed to encase and organize electrical wires and cables. Typically made from materials such as polyethylene or polypropylene, this tubing has a ribbed, corrugated structure that offers flexibility and resilience. The split aspect of split loom means it can be easily opened and closed, making it user-friendly for routing wires without the need to disassemble connections.

The most notable feature of split loom tubing is its flexibility, allowing it to be bent around corners and through tight spaces. The ribbed design also allows for air circulation around the wires, which can help in dissipating heat and preventing insulation breakdown.

Benefits of Corrugated Split Loom Tubing

1. Protection Against Physical Damage One of the primary benefits of using split loom tubing is its ability to shield wires and cables from physical abrasion, moisture, and chemicals. This is particularly important in industrial environments where wires can easily be damaged.

2. Organizing Cables In settings with numerous wires running parallel to one another, such as in industrial machinery or automotive applications, split loom tubing provides an efficient way to organize and bundle cables. This not only prevents tangling but also simplifies maintenance and troubleshooting.

3. Temperature Resistance While wire insulation has its own heat threshold, the additional layer of protection from split loom tubing can further enhance temperature resistance. This is crucial for applications that generate heat or are exposed to extreme temperatures.

4. Flexibility and Ease of Use The design of split loom tubing makes it easy to install and remove. Users can simply open the split, insert the wires, and secure it over them. This ease of installation makes it a favorite among DIY enthusiasts and professionals alike.

5. Variety of Sizes and Colors Corrugated split loom tubing is available in various sizes and colors, allowing users to choose the most appropriate type for their specific application. This flexibility ensures that one can find a suitable size for almost any wiring setup.

Applications of Corrugated Split Loom Tubing

The versatility of corrugated split loom tubing means it can be used in a wide range of applications

corrugated split loom tubing

- Automotive Industry In vehicles, split loom tubing can protect wires from heat, moisture, and abrasion. It is commonly found in engine compartments, where wires are exposed to harsh conditions.

- Industrial Machinery Manufacturing and production facilities often use split loom tubing to organize and protect wiring within machinery

. This enhances safety and reduces downtime caused by wire damage.- Home and DIY Projects Home improvement enthusiasts frequently use split loom tubing for various electrical projects, from wiring home theater systems to outdoor lighting setups.

- Aerospace In the aerospace industry, where safety is critical, corrugated split loom tubing is employed to ensure that all wiring is adequately protected from environmental factors.

How to Use Corrugated Split Loom Tubing

Using corrugated split loom tubing is straightforward

1. Measure Before cutting your tubing, measure the length you need based on the cable run.

2. Cut Use a sharp utility knife or scissors to cut the tubing neatly, ensuring there are no rough edges that might damage the wires.

3. Insert Wires Open the split of the tubing and insert the wires. If you're bundling cables, ensure they’re organized and not crammed into the tubing.

4. Secure Depending on the installation, you may want to use zip ties or additional taping to hold the loom in place.

5. Regular Inspection Periodically check the tubing for wear and tear, especially in applications exposed to harsh conditions.

Conclusion

In summary, corrugated split loom tubing is an invaluable component in protecting and organizing wires and cables across various industries and applications. Its benefits, including physical protection, flexibility, and ease of use, make it an ideal choice for both professionals and DIY enthusiasts alike. Embracing this simple yet effective product can lead to better wiring management and longevity, ensuring that your electrical systems remain robust and reliable.