Automotive Applications of Corrugated Plastic Tubing for Enhanced Durability and Flexibility

The Role of Corrugated Plastic Tubing in the Automotive Industry

In the automotive industry, innovation and efficiency are paramount. One of the materials that have gained popularity over the years is corrugated plastic tubing. This robust yet lightweight solution offers a plethora of benefits that cater to the diverse needs of automotive applications, from fluid transfer to protecting sensitive wiring.

What is Corrugated Plastic Tubing?

Corrugated plastic tubing, often made from high-density polyethylene (HDPE) or polypropylene, is characterized by its distinct wavy structure that creates a series of ridges and grooves. This design not only provides flexibility and strength but also allows for adaptability in various applications. Typically available in a range of diameters and wall thicknesses, corrugated plastic tubing can be customized to meet the specific demands of automotive projects, providing manufacturers with the versatility they need.

Advantages in Automotive Applications

1. Lightweight and Durable One of the most significant advantages of corrugated plastic tubing is its lightweight nature. Automobiles are continually striving to improve fuel efficiency, and reducing weight is a critical aspect of this. Corrugated plastic tubing offers a lightweight alternative to traditional metal or rubber hoses, thus contributing to overall vehicle efficiency without compromising on durability.

2. Chemical Resistance Automotive environments expose components to various chemicals, including oils, solvents, and other fluids. Corrugated plastic tubing is resistant to many of these substances, making it a reliable choice for applications involving fluid transfer. Its ability to withstand degradation from chemicals extends the lifespan of automotive components, thereby reducing maintenance costs and increasing vehicle reliability.

3. Flexibility and Versatility The flexibility of corrugated plastic tubing makes it ideal for routing through tight spaces within a vehicle. Whether it’s for air intake, exhaust systems, or electric wiring, this tubing can bend and curve to fit constrained areas without kinking, ensuring uninterrupted flow and functionality. This flexibility is especially beneficial in modern vehicles which are engineered with complex layouts.

4. Protection for Wiring and Hoses In addition to fluid transfer, corrugated plastic tubing serves as an excellent protective cover for wiring and hoses. It helps to prevent abrasion and damage from external elements and mechanical wear. This protective layer is essential in maintaining the integrity of sensitive wiring harnesses, which are crucial for the operation of numerous electrical systems within the vehicle.

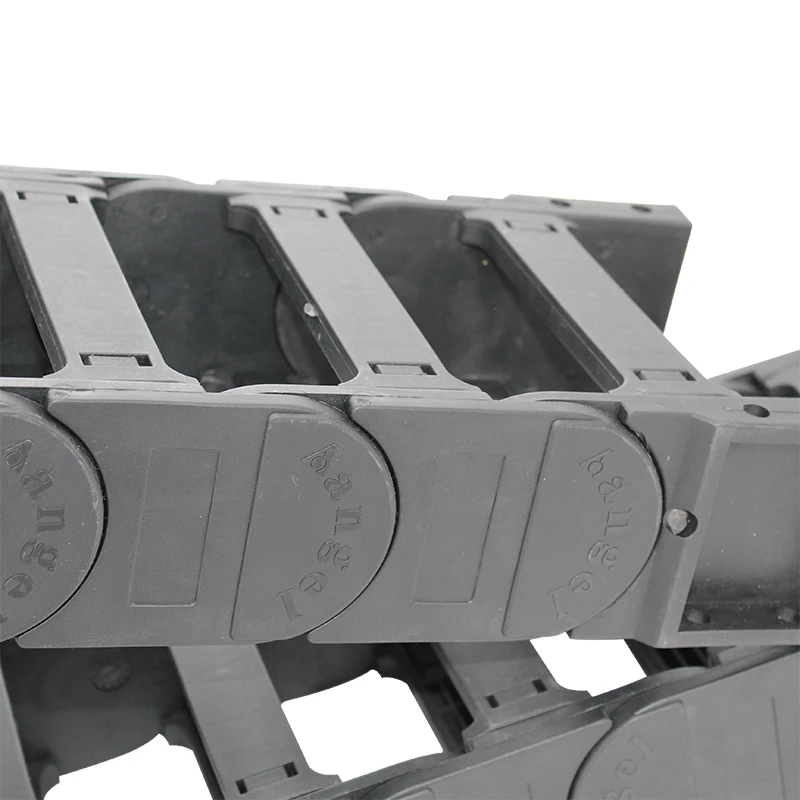

corrugated plastic tubing automotive

5. Ease of Installation Another notable advantage is the ease of installation. Corrugated plastic tubing is lightweight and can be cut to size, making it user-friendly for automotive manufacturers during assembly. Its flexibility allows it to be routed in various orientations, reducing installation time and labor costs.

Applications in the Automotive Sector

Corrugated plastic tubing finds its way into numerous automotive applications, including

- Fuel Lines The tubing is ideal for transferring fuel safely and efficiently. Its chemical resistance ensures the integrity of the system even under high pressure. - Ducting In heating, ventilation, and air conditioning (HVAC) systems, corrugated plastic tubing is used to distribute air efficiently while minimizing leaks.

- Electrical Applications As a protective covering for wiring harnesses, it shields electrical components from physical damage and exposure to moisture.

- Vacuum Lines Its flexibility allows corrugated plastic tubing to be used in vacuum lines, ensuring reliable performance in various vehicle systems.

Conclusion

As the automotive industry continues to evolve with advancements in technology and materials science, the role of corrugated plastic tubing is becoming increasingly prominent. Its lightweight, durable, and flexible nature complements modern vehicle designs and performance demands. In an era where efficiency and sustainability are at the forefront, incorporating such innovative materials is crucial for automotive manufacturers looking to enhance their products while meeting regulatory standards and consumer expectations.

In conclusion, corrugated plastic tubing stands as a vital component in the automotive supply chain, providing benefits that align with the industry's push towards innovation and efficiency. As manufacturers embrace this material, we can expect to see even greater advancements in vehicle design and performance in the years to come.