Automotive Applications of Corrugated Plastic Tubing for Enhanced Durability and Flexibility

The Role of Corrugated Plastic Tubing in the Automotive Industry

In the automotive industry, the quest for lightweight, durable, and cost-effective materials has always been paramount. One such innovative solution that has gained traction in recent years is corrugated plastic tubing. This versatile material has found its applications in various automotive components, thanks to its unique properties.

What is Corrugated Plastic Tubing?

Corrugated plastic tubing is manufactured from high-density polyethylene (HDPE) or polypropylene, which are both known for their strength and resistance to a variety of environmental conditions. The tubing features a ridged or corrugated design that enhances its flexibility while maintaining structural integrity. This design also contributes to the lightweight nature of the tubing, making it an attractive alternative for automotive applications where weight reduction is critical.

Benefits of Corrugated Plastic Tubing in Automotive Applications

1. Lightweight and Durable One of the standout features of corrugated plastic tubing is its lightweight nature. In an industry where reducing weight plays a vital role in improving fuel efficiency and overall performance, using corrugated plastic can contribute significantly without compromising strength. This tubing is resistant to impacts, abrasion, and chemicals, ensuring longevity and reliability in harsh automotive environments.

2. Flexibility and Versatility The flexibility of corrugated plastic tubing allows for easy routing and installation in various automotive systems. It can be bent and shaped to accommodate different layouts without the risk of kinking or breaking. This versatility is especially beneficial for complex assemblies, such as those found in engine compartments and undercarriages, where space constraints are common.

3. Resistance to Environmental Factors Automobiles are subjected to various challenging conditions, including extreme temperatures, moisture, and exposure to chemicals. Corrugated plastic tubing offers excellent resistance to these conditions. It does not corrode like metal tubing and can withstand UV exposure, making it suitable for both interior and exterior automotive applications.

4. Cost-Effectiveness When considering the total cost of ownership, corrugated plastic tubing can provide significant cost savings. Its lightweight nature contributes to fuel efficiency, and its durability reduces the need for frequent replacements. Moreover, the production process for corrugated plastic tubing is efficient, leading to lower manufacturing costs compared to traditional materials.

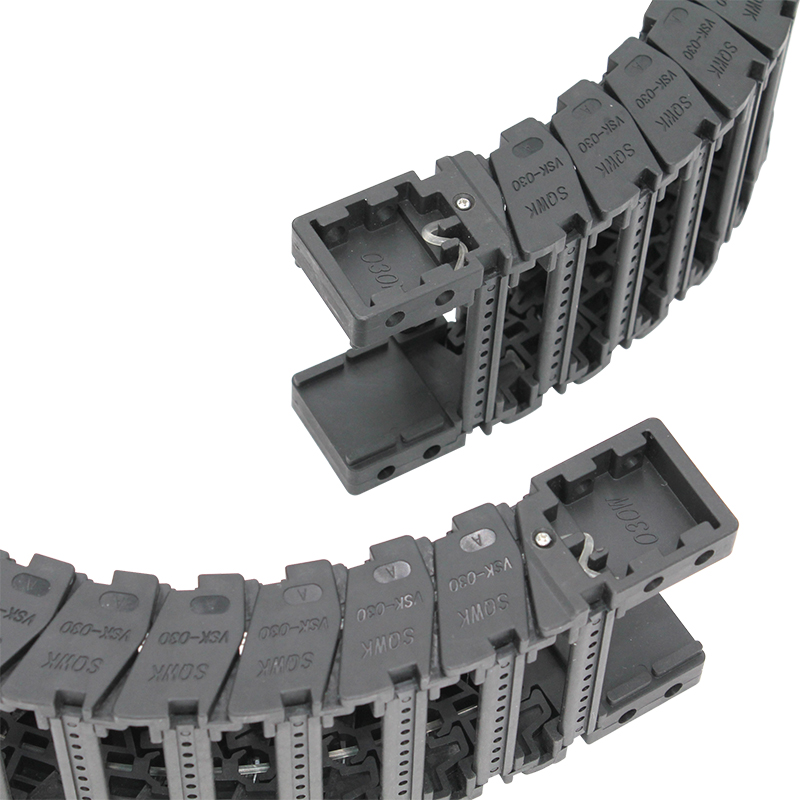

corrugated plastic tubing automotive

Applications in the Automotive Domain

Corrugated plastic tubing is used in various automotive applications, including

- Fluid Transfer The tubing is commonly used for transferring liquids, such as fuel, oil, and coolant, due to its resistance to punctures and leaks. Its ability to bend and fit into tight spaces makes it ideal for routing fluids through complex engine configurations.

- Wiring Protection In automotive electrical systems, corrugated plastic tubing is utilized to protect wiring harnesses from abrasion and environmental damage. The tubing helps maintain the integrity of electrical connections, reducing the risk of shorts or failures.

- Ventilation Systems The automotive ventilation systems, which ensure passenger comfort, often employ corrugated plastic tubing to channel air. Its lightweight and flexible nature allows it to be easily integrated into the vehicle's design.

- Hoses for Active Systems Active control systems, such as those used in turbochargers and intercoolers, benefit from corrugated plastic tubing due to its ability to handle varying pressures and temperatures effectively.

Conclusion

As the automotive industry continues to innovate and move towards more efficient, reliable, and sustainable solutions, corrugated plastic tubing stands out as a valuable material. Its combination of lightweight, durability, flexibility, and resistance to harsh conditions makes it an ideal choice for a wide range of automotive applications. As manufacturers increasingly prioritize efficiency and cost-effectiveness, the use of corrugated plastic tubing is likely to expand, further solidifying its role in the automotive landscape. With ongoing advancements in material science and manufacturing processes, the future looks promising for this versatile tubing solution in the automotive sector.