corrugated plastic tubing automotive

Corrugated Plastic Tubing in the Automotive Industry

The automotive industry is constantly evolving, seeking innovative materials that enhance performance, safety, and efficiency. One such material that has gained traction in recent years is corrugated plastic tubing. This versatile solution is becoming increasingly important in various automotive applications, offering a range of benefits that cater to the needs of modern vehicles.

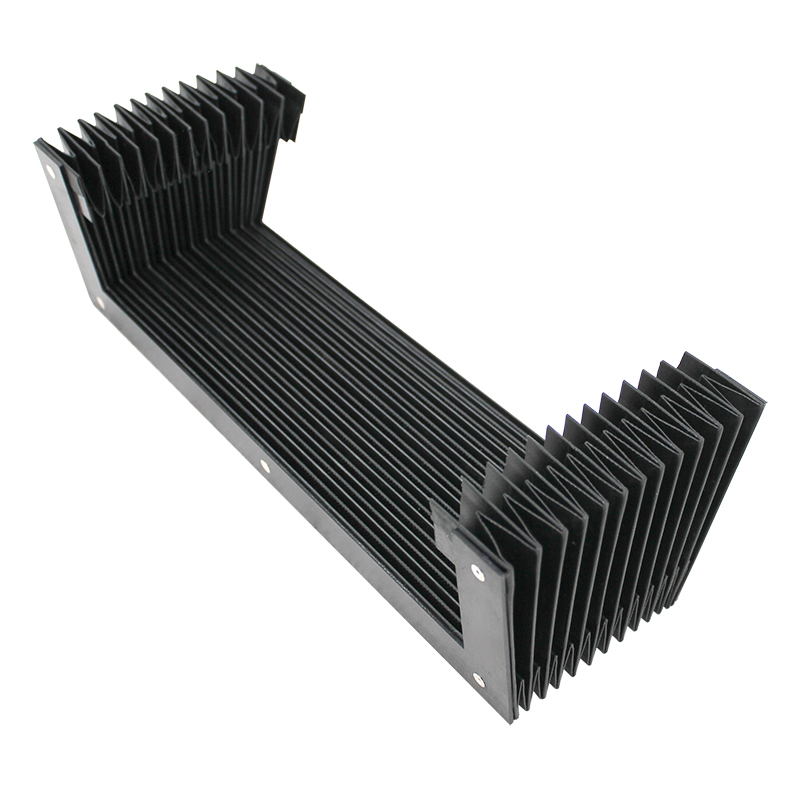

Corrugated plastic tubing, often made from high-density polyethylene (HDPE) or polypropylene, is characterized by its unique structure of alternating ridges and grooves. This design provides inherent flexibility, lightweight properties, and excellent resistance to environmental factors such as moisture, chemicals, and UV rays. These features make corrugated plastic tubing especially suitable for automotive applications, where durability and performance are of utmost importance.

One of the primary uses of corrugated plastic tubing in the automotive industry is for wiring harnesses. The electrical systems in vehicles have grown increasingly complex, necessitating effective organization and protection of wiring. Corrugated plastic tubing serves as an ideal conduit for electrical wires, shielding them from abrasion, moisture, and heat. The lightweight nature of this tubing also helps reduce the overall weight of the vehicle, contributing to improved fuel efficiency.

In addition to electrical applications, corrugated plastic tubing is frequently used for fluid management systems in vehicles. It can accommodate the transportation of various fluids, including fuel, coolant, and transmission fluid. The flexible design allows for easy routing around tight spaces in the engine compartment or chassis, while the material's resistance to corrosion ensures a long-lasting solution. This is particularly beneficial in applications where durability is critical, such as in high-performance or off-road vehicles.

corrugated plastic tubing automotive

Another significant advantage of corrugated plastic tubing is its ease of installation. Traditional metal tubing or rigid plastic alternatives often require complex fittings and connectors, which can increase installation time and costs. In contrast, the flexibility of corrugated tubing allows for simpler, quicker installations, making it an attractive option for manufacturers looking to streamline their production processes. Furthermore, the reduced need for additional fittings can lead to savings in both materials and labor costs.

Moreover, corrugated plastic tubing is environmentally friendly. As manufacturers become more conscious of their ecological footprint, the choice of materials is increasingly scrutinized. Corrugated plastic tubing can be recycled, allowing for a more sustainable approach to automotive manufacturing. This aspect aligns with the broader industry trend towards sustainable practices and the use of recyclable materials in production.

The automotive industry has also seen advancements in the formulation of corrugated plastic tubing. Manufacturers are now able to produce tubing with enhanced properties such as increased fire resistance, improved temperature tolerance, and even antistatic capabilities. This innovation ensures that the tubing can meet the specific demands of various environments and applications, making it a suitable choice for a wide range of vehicles, from electric cars to traditional gasoline-powered models.

In conclusion, corrugated plastic tubing is making a significant impact in the automotive industry due to its versatility, durability, and ease of use. Its applications in wiring harnesses and fluid management systems not only enhance vehicle performance but also contribute to more sustainable manufacturing practices. As the automotive sector continues to innovate and seek out materials that meet modern demands, corrugated plastic tubing is poised to remain a key component in the development of the vehicles of the future. Its unique properties not only improve functionality but also play a vital role in the overall efficiency and sustainability of automotive design.