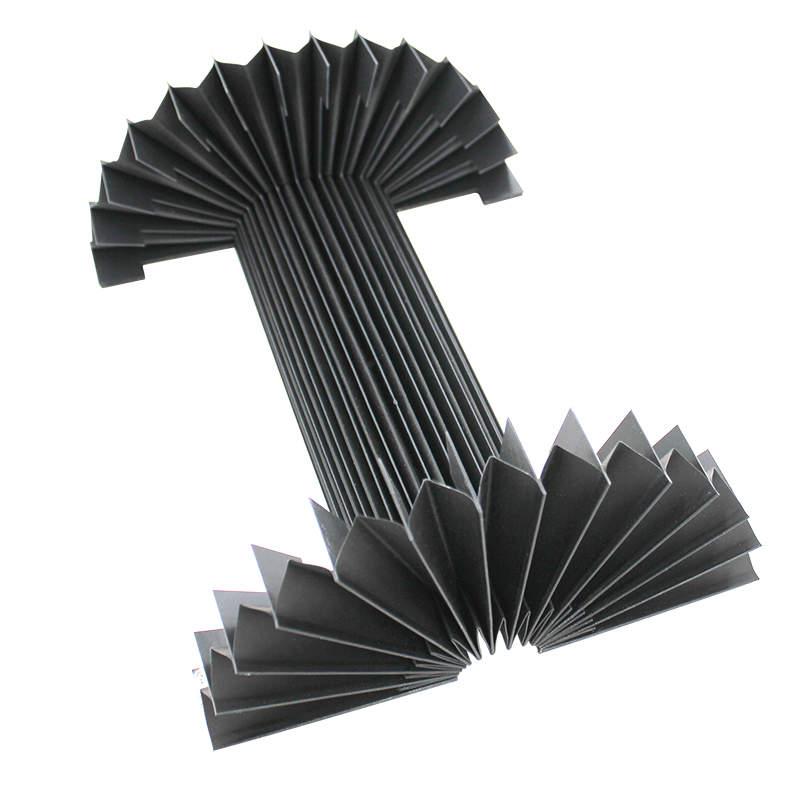

corrugated plastic tubing

The Versatility of Corrugated Plastic Tubing

Corrugated plastic tubing, often referred to as a bellows or simply corrugated tubing, is a versatile material that has gained popularity across various industries due to its unique combination of durability, flexibility, and light weight. This article will explore the various applications of corrugated plastic tubing, its advantages, and its future potential in numerous fields.

What is Corrugated Plastic Tubing?

Corrugated plastic tubing is made from high-density polyethylene (HDPE) or polypropylene, which gives it strength and resilience. The tubing consists of a series of ridges and grooves, providing flexibility while maintaining structural integrity. This design enables the tubing to bend and flex without breaking, making it an ideal choice for applications that require movement or adjustments.

Applications of Corrugated Plastic Tubing

1. Hydraulic and Pneumatic Systems One of the primary uses for corrugated plastic tubing is in hydraulic and pneumatic systems. The tubing can easily handle air and fluid transfer, effectively routing these materials through machinery and equipment. Its lightweight nature helps reduce the overall weight of systems, contributing to increased efficiency.

2. Electrical Conduits The tubing is also commonly used as protective conduits for electrical wiring. Thanks to its ability to resist chemicals and corrosion, corrugated plastic tubing safeguards electrical cables from environmental damage, moisture, and mechanical impacts, ensuring continuous operation and safety.

3. Agricultural Uses In agriculture, the tubing is often employed for irrigation systems. Its flexibility allows farmers to easily set up and modify irrigation lines to suit the contours of their fields. The durability of corrugated plastic tubing also ensures long-lasting performance, reducing the need for frequent replacements.

4. HVAC Systems In heating, ventilation, and air conditioning systems, corrugated plastic tubing plays a crucial role in air distribution. The lightweight and flexible nature of the tubing allows for easy routing through tight spaces, ensuring proper airflow and ventilation in residential and commercial environments.

5. Industrial Applications Corrugated plastic tubing is extensively used in various industrial settings, ranging from manufacturing to warehousing. It is used for packaging components, organizing cables, and protecting sensitive equipment during transit. The tubing's ability to withstand high temperatures and mechanical stresses makes it an invaluable resource in these environments.

corrugated plastic tubing

Advantages of Corrugated Plastic Tubing

The use of corrugated plastic tubing comes with several advantages that make it a preferred choice across industries

1. Durability Corrugated plastic tubing is designed to withstand environmental stressors, including temperature fluctuations, UV exposure, and various chemicals. This durability translates to a longer lifespan compared to other tubing materials.

2. Lightweight Design The lightweight nature of corrugated plastic tubing facilitates easier handling and installation. This characteristic is particularly beneficial in applications where weight reduction is crucial.

3. Flexibility The corrugated design allows the tubing to bend around corners and obstacles easily, making it particularly useful in tight spaces or complex layouts.

4. Cost-Effective With its long-lasting properties and minimal maintenance requirements, corrugated plastic tubing is a cost-effective solution for many applications. Its durability reduces replacement costs, while its lightweight nature can lower transportation expenses.

5. Recyclable Many types of corrugated plastic tubing are recyclable, making it an environmentally friendly option for businesses seeking to reduce their ecological footprint. The sustainability aspect can be a significant factor for companies committed to green practices.

Future Potential

As industries continue to evolve, the demand for innovative and efficient materials like corrugated plastic tubing is likely to grow. With advancements in manufacturing techniques and increased awareness of sustainability, future iterations of this versatile product may incorporate enhanced features such as improved temperature resistance or biopolymers for even greener applications.

In conclusion, corrugated plastic tubing stands out as a resilient, lightweight, and flexible material with broad applications across various sectors. Its advantages not only contribute to operational efficiency but also support sustainability efforts. As industries seek to innovate and adapt to new challenges, the importance of materials like corrugated plastic tubing will undoubtedly increase, paving the way for more efficient designs and solutions in various fields.