corrugated plastic conduit

Understanding Corrugated Plastic Conduit

Corrugated plastic conduit, often referred to as corrugated ducting or flexible conduit, has emerged as a favored choice for various electrical and utility applications. This versatile product, made from durable plastic material, exhibits a range of advantageous properties that cater to the needs of both residential and commercial setups.

What is Corrugated Plastic Conduit?

Corrugated plastic conduit is a type of tubing characterized by its ribbed outer surface, which provides enhanced flexibility and strength. Unlike traditional rigid conduits made from metal or rigid PVC, corrugated plastic conduits can bend and twist without compromising their structural integrity. The most common material used for these conduits is high-density polyethylene (HDPE), known for its resilience and longevity.

Key Features and Benefits

1. Flexibility One of the significant advantages of corrugated plastic conduit is its flexibility. This characteristic allows it to navigate around corners and obstacles easily, making installation straightforward in tight or complex spaces. This adaptability is especially useful in applications where conventional rigid conduit might be cumbersome or impossible to install.

2. Lightweight Design Compared to alternatives like metal conduits, corrugated plastic conduits are significantly lighter. This lightweight nature reduces shipping and handling costs and makes the installation process more efficient, as workers can easily transport and manipulate the conduit.

3. Corrosion Resistance Corrugated plastic is inherently resistant to moisture and chemicals, unlike metal conduits that are prone to rust and corrosion over time. This resistance makes plastic conduits ideal for use in harsh environments, including underground or in areas exposed to chemicals.

4. Cost-Effective The affordability of corrugated plastic conduit plays a vital role in its widespread adoption. When considering material costs, installation, and longevity, businesses and homeowners find that it offers an economically feasible solution for electrical and plumbing tasks.

corrugated plastic conduit

5. Electrical Insulation As a non-conductive material, corrugated plastic conduit provides excellent electrical insulation. This characteristic minimizes the risk of electrical hazards, making it a safe choice for protecting wiring and cables in various settings.

Applications

Corrugated plastic conduits find applications across multiple sectors. In residential settings, they are commonly used for electrical wiring, cable protection, and plumbing systems. In commercial environments, these conduits serve not only electrical systems but also telecommunications wiring, data transmission cables, and even irrigation systems.

Furthermore, their use is quite prevalent in the construction industry, where builders utilize these conduits for temporary installations. They are also favored in outdoor applications, such as protecting wiring in landscaping projects, where exposure to the elements is a concern.

Installation Considerations

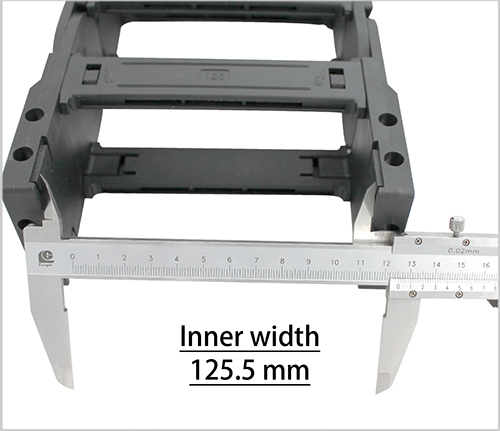

While the installation of corrugated plastic conduit is generally straightforward, proper planning is essential for optimal results. Users should ensure that the conduit size is adequate for the intended wiring or plumbing and that installation complies with local building codes. Moreover, protective fittings and junction boxes should match the conduit to maintain the overall system's integrity.

Conclusion

In conclusion, corrugated plastic conduit represents a modern solution to the challenges of electrical and utility applications. Its unmatched flexibility, lightweight design, corrosion resistance, cost-effectiveness, and excellent insulation properties make it a reliable choice for a variety of installations. As industries continue to evolve, the demand for such innovative materials will likely increase, solidifying the standing of corrugated plastic conduit as a staple in both residential and commercial applications. By understanding its features and benefits, users can make informed choices that enhance safety and efficiency in their projects.