Understanding the Benefits of Corrugated Metal Conduit for Electrical Installations and Protection

The Benefits of Corrugated Metal Conduit in Electrical Installations

Corrugated metal conduit (CMC) is a versatile and robust solution widely utilized in electrical installations. Its unique design combines strength, flexibility, and durability, making it an ideal choice for protecting electrical wiring in various environments. In this article, we will explore the features and advantages of corrugated metal conduit, as well as its applications in the field.

Design and Structure

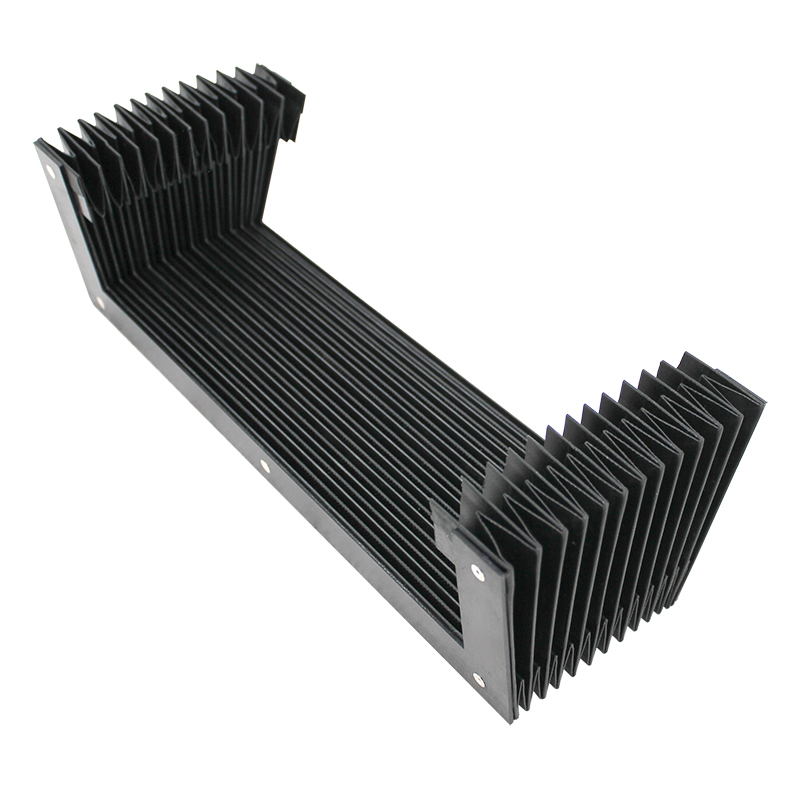

Corrugated metal conduit is characterized by its ribbed structure, which allows for greater flexibility compared to rigid conduits. The corrugations provide additional strength, enabling the conduit to withstand mechanical stress and resist deformation. Typically made from galvanized steel or aluminum, CMC can also be coated to enhance its corrosion resistance, making it suitable for both indoor and outdoor installations.

Ease of Installation

One of the key benefits of corrugated metal conduit is its ease of installation. The flexible nature of the conduit allows electricians to navigate around obstacles easily and make complex bends without needing additional fittings. This flexibility can significantly reduce installation time and labor costs. Moreover, CMC is available in various diameters, accommodating different sizes of wiring and making it adaptable to a wide range of projects.

Durability and Protection

corrugated metal conduit

Corrugated metal conduit offers exceptional durability, protecting electrical wiring from physical damage and environmental hazards. Its robust construction makes it resistant to impact, moisture, and chemical exposure, which is crucial in industrial settings where harsh conditions are prevalent. Additionally, its ability to prevent moisture infiltration helps to reduce the risk of corrosion within the conduit's interior and protects the wiring from short circuits and electrical failures.

Fire Resistance

With increasing safety concerns in electrical installations, the fire resistance of materials is paramount. Corrugated metal conduit is inherently non-combustible, providing an added layer of safety in case of electrical faults or overheating. This feature makes it a preferred choice for applications in commercial and industrial settings where fire risks are higher.

Applications

The applications of corrugated metal conduit are vast. It is frequently used in industrial environments, such as factories and warehouses, where heavy machinery and equipment demand robust electrical protection. Additionally, it is common in outdoor settings, such as utility installations and telecommunications, where exposure to weather elements is a concern. Its flexibility allows for installations in tight spaces, making it suitable for residential projects as well.

Conclusion

In summary, corrugated metal conduit presents a multitude of advantages for electrical installations. Its combination of flexibility, durability, and fire resistance makes it a reliable choice for various applications. As industries continue to prioritize safety and efficiency, the demand for versatile solutions like CMC is likely to increase. Whether for industrial use, outdoor installations, or complex residential projects, corrugated metal conduit remains an essential element in ensuring the secure and effective management of electrical systems.