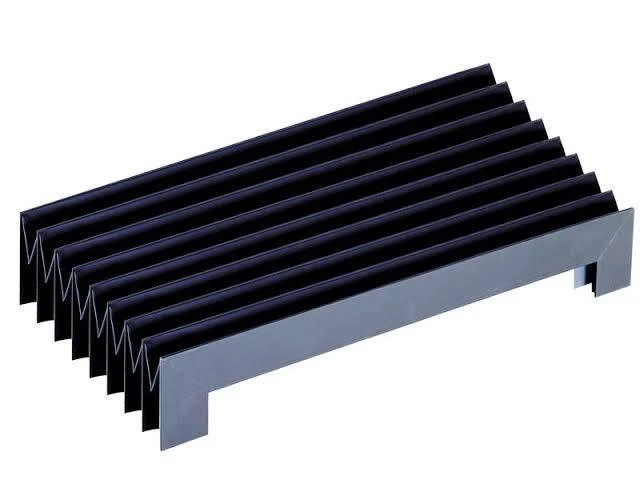

corrugated loom tubing

Corrugated loom tubing has quickly become an integral component in various industrial and consumer applications due to its exceptional qualities and versatility. This particular type of tubing is designed to offer a flexible, durable, and protective pathway for electrical wires, cables, and other conduits. With the growing demand for efficient and reliable wire management and protection solutions, it's essential to delve into the unique attributes, applications, and benefits of corrugated loom tubing to better understand its role in modern technology.

Industrial environments pose some of the harshest conditions for electrical components, and corrugated loom tubing rises to the occasion by offering unparalleled protection. In factories, warehouses, and construction sites, where exposure to dust, debris, and mechanical impact is common, this tubing ensures that wires remain intact and operational. It minimizes the risk of damage and downtime, thus enhancing productivity and efficiency. Moreover, its inherent flexibility allows it to accommodate the dynamic nature of such environments, where machinery and equipment configurations can often change. Apart from its protective properties, corrugated loom tubing is also valued for its ease of installation. The design typically allows for convenient access to wires, which can be inserted or removed without special tools. This feature is particularly beneficial in scenarios that require frequent modifications or updates to wire configurations. Additionally, many variants come with self-locking capabilities that further simplify the installation process and enhance security by preventing accidental disconnection. Considering the ever-evolving landscape of technology and the consistent need for safe and efficient cable management, it's no surprise that corrugated loom tubing continues to experience widespread adoption. Its adaptability to meet the diverse needs of various industries, combined with its superior protective qualities, makes it an indispensable tool in modern engineering. Furthermore, as concerns regarding safety and sustainability grow, advancements in the materials and design of corrugated loom tubing promise to deliver even greater benefits, such as improved heat resistance or the use of recyclable materials. In conclusion, corrugated loom tubing represents a sophisticated and essential advancement in wire management technology. Its design and material construction offer a compelling combination of flexibility, durability, and protection that meets and exceeds the demands of numerous applications. With the constant push towards innovation and efficiency, it stands as a testament to human ingenuity in solving complex problems simply and effectively. As technologies advance and industries expand, the role of corrugated loom tubing is poised to become even more influential, driving future progress through reliable and innovative wire management solutions.

Industrial environments pose some of the harshest conditions for electrical components, and corrugated loom tubing rises to the occasion by offering unparalleled protection. In factories, warehouses, and construction sites, where exposure to dust, debris, and mechanical impact is common, this tubing ensures that wires remain intact and operational. It minimizes the risk of damage and downtime, thus enhancing productivity and efficiency. Moreover, its inherent flexibility allows it to accommodate the dynamic nature of such environments, where machinery and equipment configurations can often change. Apart from its protective properties, corrugated loom tubing is also valued for its ease of installation. The design typically allows for convenient access to wires, which can be inserted or removed without special tools. This feature is particularly beneficial in scenarios that require frequent modifications or updates to wire configurations. Additionally, many variants come with self-locking capabilities that further simplify the installation process and enhance security by preventing accidental disconnection. Considering the ever-evolving landscape of technology and the consistent need for safe and efficient cable management, it's no surprise that corrugated loom tubing continues to experience widespread adoption. Its adaptability to meet the diverse needs of various industries, combined with its superior protective qualities, makes it an indispensable tool in modern engineering. Furthermore, as concerns regarding safety and sustainability grow, advancements in the materials and design of corrugated loom tubing promise to deliver even greater benefits, such as improved heat resistance or the use of recyclable materials. In conclusion, corrugated loom tubing represents a sophisticated and essential advancement in wire management technology. Its design and material construction offer a compelling combination of flexibility, durability, and protection that meets and exceeds the demands of numerous applications. With the constant push towards innovation and efficiency, it stands as a testament to human ingenuity in solving complex problems simply and effectively. As technologies advance and industries expand, the role of corrugated loom tubing is poised to become even more influential, driving future progress through reliable and innovative wire management solutions.