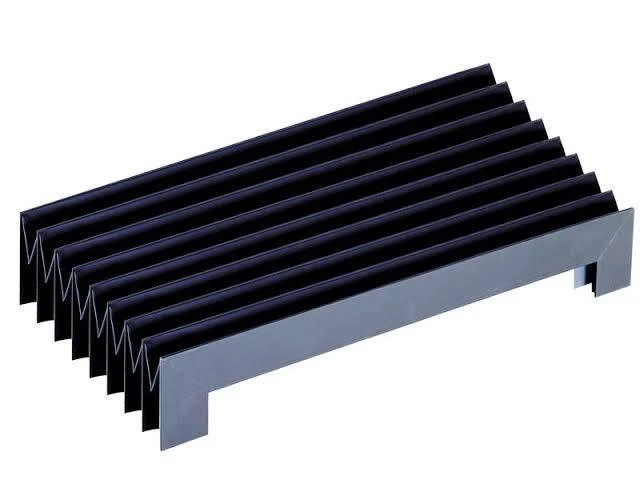

corrugated loom tubing

Navigating the complex world of automotive and industrial cables often feels like a daunting task. However, choosing the right protective solutions, such as corrugated loom tubing, can make a significant difference. Picture this a robust yet flexible casing that shields delicate wires from external damage while optimizing both functionality and safety. Corrugated loom tubing achieves this and more, providing unmatched protection against heat, abrasion, and mechanical strain.

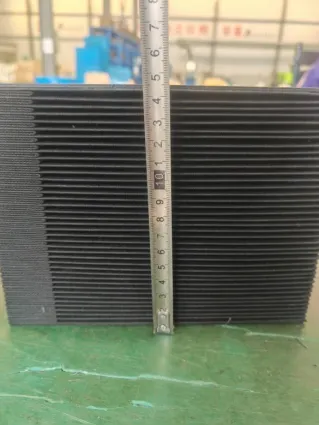

Producers of corrugated loom tubing have profoundly influenced the market by emphasizing authoritativeness in their manufacturing processes. Established brands ensure adherence to stringent quality control measures, thereby affirming that their products meet or exceed safety and performance benchmarks. These companies often collaborate with industry regulatory bodies to stay at the forefront of safety and innovation, further underscoring their authority in the field. Trustworthiness is a pillar of corrugated loom tubing's reputation, with countless user reviews and case studies reinforcing its reliability. A common scenario observed is its performance under extreme conditions. For instance, vehicle technicians note that when used within engine compartments or areas exposed to varying temperatures, the tubing maintains its integrity without cracking or warping. This kind of real-world proof substantiates the trust professionals place in such products. The track record of reliability that corrugated loom tubing maintains establishes an unwavering confidence in its continued performance, a critical factor for users prioritizing long-term solutions. In conclusion, the role of corrugated loom tubing is indisputable across many sectors. Identifying a product that consistently combines installation ease, expert engineering, market authority, and proven reliability is rare. As the demands on wiring systems progress and expand, the significance of such protective solutions will only grow. Corrugated loom tubing emerges not merely as a choice but as an essential component for those invested in safeguarding their electrical systems against the unpredictable challenges of everyday operation.

Producers of corrugated loom tubing have profoundly influenced the market by emphasizing authoritativeness in their manufacturing processes. Established brands ensure adherence to stringent quality control measures, thereby affirming that their products meet or exceed safety and performance benchmarks. These companies often collaborate with industry regulatory bodies to stay at the forefront of safety and innovation, further underscoring their authority in the field. Trustworthiness is a pillar of corrugated loom tubing's reputation, with countless user reviews and case studies reinforcing its reliability. A common scenario observed is its performance under extreme conditions. For instance, vehicle technicians note that when used within engine compartments or areas exposed to varying temperatures, the tubing maintains its integrity without cracking or warping. This kind of real-world proof substantiates the trust professionals place in such products. The track record of reliability that corrugated loom tubing maintains establishes an unwavering confidence in its continued performance, a critical factor for users prioritizing long-term solutions. In conclusion, the role of corrugated loom tubing is indisputable across many sectors. Identifying a product that consistently combines installation ease, expert engineering, market authority, and proven reliability is rare. As the demands on wiring systems progress and expand, the significance of such protective solutions will only grow. Corrugated loom tubing emerges not merely as a choice but as an essential component for those invested in safeguarding their electrical systems against the unpredictable challenges of everyday operation.