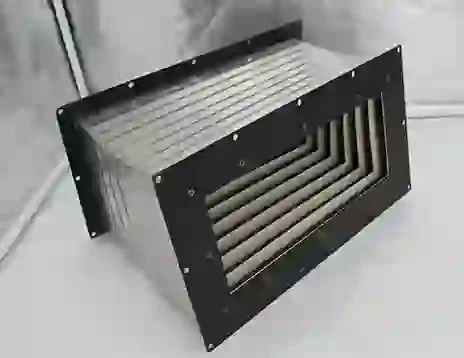

corrugated flexible tube

Understanding Corrugated Flexible Tubes An Essential Component in Modern Industries

Corrugated flexible tubes are integral components in various industries, providing crucial solutions for fluid and gas management. These tubes, distinguished by their unique corrugated design, offer superior flexibility, durability, and resistance to external factors, making them ideal for numerous applications. In this article, we will explore the advantages, applications, and materials used in the manufacture of corrugated flexible tubes.

One of the most significant advantages of corrugated flexible tubes is their remarkable flexibility. The corrugated structure allows these tubes to bend and twist easily without kinking, which is essential in scenarios where routing through tight spaces is necessary. This flexibility also means that they can absorb vibrations and accommodate movements, making them an excellent choice for dynamic environments, such as automotive and aerospace applications.

Durability is another key attribute of these tubes. Made from various materials, including plastics, rubber, and metals, corrugated flexible tubes are designed to withstand a range of harsh conditions. This includes exposure to extreme temperatures, chemicals, and physical stress. For instance, a polyvinyl chloride (PVC) corrugated tube can endure significant abrasion and is resistant to corrosive substances, making it suitable for industrial drainage systems. Likewise, metal options, such as stainless steel, provide additional strength and resistance to high pressures.

When it comes to applications, corrugated flexible tubes are incredibly versatile. In the automotive industry, they are commonly used for fuel and air intake systems, as well as for cooling systems. Their flexible nature allows for easier installation and adaptability to different engine layouts. In the construction sector, these tubes are often utilized for electrical conduits and as protective coverings for wiring, owing to their ability to shield from dust and moisture.

corrugated flexible tube

In the agricultural sector, corrugated flexible tubes play a vital role in irrigation systems. They enable efficient water management by transporting water from sources to crops, while their flexibility allows them to adapt to varying terrains. Additionally, in HVAC (heating, ventilation, and air conditioning) systems, these tubes effectively transport air, ensuring optimal airflow and system efficiency.

The manufacturing process of corrugated flexible tubes involves various methods tailored to the specific materials used. Extrusion is a common process for plastic tubes, wherein heated material is forced through a die to create continuous lengths of tubing. For rubber and metal tubes, processes such as molding and rolling are employed. Quality control is paramount, with strict testing protocols to ensure that the tubes meet industry standards for performance and safety.

Moreover, technological advancements in materials and manufacturing techniques are driving innovation in the design of corrugated flexible tubes. The introduction of lightweight composites and enhanced rubber formulations has led to even better performance characteristics, catering to the evolving demands of modern industries.

In conclusion, corrugated flexible tubes are more than just conduits; they are essential components that support the functionality and efficiency of numerous systems across various industries. Their flexibility, durability, and versatility make them an indispensable choice for applications ranging from automotive to agriculture. As technology continues to advance, the future of corrugated flexible tubes promises even greater innovations, solidifying their place as a vital aspect of industrial operations.