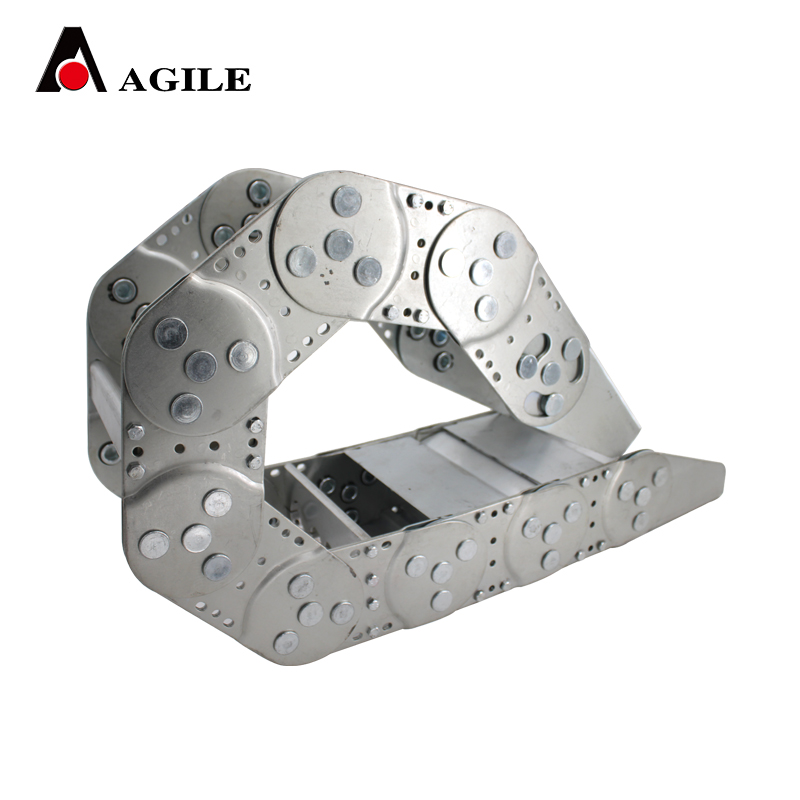

corrugated electrical tubing

The Importance of Corrugated Electrical Tubing in Modern Electrical Applications

In today's rapidly evolving technological landscape, electrical safety and efficiency are paramount considerations for any construction or installation project. Among the various products designed to protect and manage electrical wiring, corrugated electrical tubing has emerged as a reliable solution, offering numerous advantages that cater to the needs of both electrical engineers and contractors.

What is Corrugated Electrical Tubing?

Corrugated electrical tubing, often referred to as flexible conduit, is a type of protective casing used to route electrical wiring. Made from a variety of materials, such as PVC (polyvinyl chloride) or various forms of metal, this tubing is characterized by its distinct ridged surface, which provides flexibility and strength. The corrugated design allows the tubing to bend around obstacles and fit into tight spaces, making it an ideal choice for a range of applications.

Advantages of Corrugated Electrical Tubing

The utilization of corrugated electrical tubing offers several key benefits

1. Flexibility and Versatility One of the standout features of corrugated electrical tubing is its flexibility. Unlike rigid conduits, the corrugated design allows for easy installation in spaces that require complex routing. This versatility is especially beneficial in environments where wires need to navigate around corners or follow irregular paths.

2. Protection Against Environmental Hazards Electrical installations are often exposed to harsh conditions, whether it be moisture, chemicals, or physical impacts. Corrugated electrical tubing acts as a barrier, safeguarding wires from environmental hazards. This is particularly crucial in industrial settings or outdoor applications, where exposure to potential damage can lead to hazards or electrical failures.

3. Ease of Installation The lightweight nature and flexibility of corrugated tubing contribute to its user-friendly installation process. Electricians and contractors can easily cut and assemble segments of tubing, reducing the time required for installation and minimizing labor costs.

4. Reduced Risk of Electrocution The non-conductive properties of materials like PVC can significantly lower the risk of electrocution. This provides an additional layer of safety in residential and commercial installations, where human contact with electrical systems is a possibility.

corrugated electrical tubing

5. Cost-Effectiveness Compared to rigid conduit systems, corrugated electrical tubing is generally more cost-effective. The combination of lower material costs and reduced labor time during installation often results in overall savings for projects that require extensive wiring setups.

6. Fire Safety Many corrugated electrical tubing products are designed to be flame-retardant. This feature is essential in commercial buildings and industrial applications where fire safety codes must be adhered to. The right choice of tubing can help prevent fire hazards associated with electrical installations.

Applications of Corrugated Electrical Tubing

Corrugated electrical tubing finds applications across various sectors, including

- Residential Projects In home wiring installations, corrugated tubing is often used to protect wiring from damage and ensure proper routing throughout the structure.

- Industrial Settings Factories and manufacturing plants frequently employ corrugated tubing in environments where wires may be exposed to oil, dirt, and other substances. Its robust protective qualities enable it to thrive in such challenging conditions.

- Telecommunications In telecom setups, the need for well-protected wiring is critical for system reliability. Corrugated electrical tubing ensures that sensitive cables remain safe from external damage.

- Automotive and Aerospace The automotive and aerospace industries utilize corrugated tubing to protect wiring harnesses, sensors, and other electrical components from wear and tear due to vibrations and movement.

Conclusion

As technology continues to advance and the need for safe, reliable electrical systems grows, the importance of effective wiring management becomes increasingly clear. Corrugated electrical tubing stands out as an exceptional solution, combining flexibility, durability, and safety features that cater to a wide range of applications. From residential buildings to high-tech industrial environments, its role cannot be understated in ensuring that our electrical systems operate safely and efficiently. The choice to incorporate corrugated electrical tubing into projects is not just a matter of practicality; it’s a commitment to quality and safety in electrical installations.