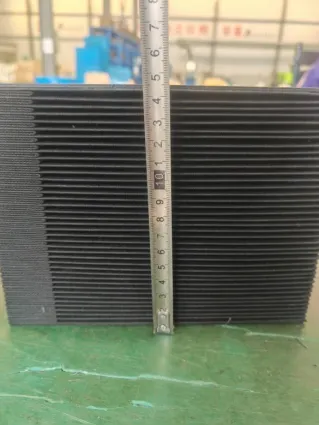

nylon flexible wire loom corrugated bellow conduit hose pipe

Navigating the realms of corrugated conduit sizes can be complex, especially for professionals looking to optimize their electrical or communication installations. Understanding the intricacies of these materials is crucial not only for effective installations but also for ensuring safety and compliance with industry standards. With years of experience and a deep expertise in electrical conduits, this guide is crafted to offer authoritative insights and trustworthy advice.

Regulatory compliance adds another layer of complexity to the decision-making process. Different regions have varied codes and standards that specify requirements for conduit installation, including size. Familiarity with these regulations is crucial, as non-compliance can lead to costly rework or penalties. Consulting the National Electrical Code (NEC) or local electrical codes can provide guidance on the required conduit sizes for different applications. Manufacturers and suppliers also play a significant role in determining the success of a conduit installation. Opting for quality brands that are known for their reliability in manufacturing can prevent issues related to material defects or underperformance. Establishing a relationship with trusted suppliers can also provide access to the latest innovations in conduit materials and design. In recent years, technological advancements have introduced conduits with added features such as enhanced fire resistance, improved flexibility, and integrated pathways for different types of cables. These developments can influence size selection as they provide opportunities for more streamlined installations, potentially reducing the need for extensive conduit systems. Real-world experience attests to the importance of considering both the immediate requirements and the long-term implications when selecting conduit sizes. Engineers and contractors who balance these factors benefit from installations that not only meet current needs but are also poised for future upgrades. In conclusion, the process of selecting the appropriate corrugated conduit size is multifaceted, requiring a balance of technical understanding, practical foresight, and adherence to regulatory standards. By thoroughly evaluating these elements, professionals can ensure that their conduit systems are both efficient and compliant. Emphasizing quality and strategic planning in the selection process adds a layer of trustworthiness and credibility to each project, ultimately contributing to safer and more reliable installations.

Regulatory compliance adds another layer of complexity to the decision-making process. Different regions have varied codes and standards that specify requirements for conduit installation, including size. Familiarity with these regulations is crucial, as non-compliance can lead to costly rework or penalties. Consulting the National Electrical Code (NEC) or local electrical codes can provide guidance on the required conduit sizes for different applications. Manufacturers and suppliers also play a significant role in determining the success of a conduit installation. Opting for quality brands that are known for their reliability in manufacturing can prevent issues related to material defects or underperformance. Establishing a relationship with trusted suppliers can also provide access to the latest innovations in conduit materials and design. In recent years, technological advancements have introduced conduits with added features such as enhanced fire resistance, improved flexibility, and integrated pathways for different types of cables. These developments can influence size selection as they provide opportunities for more streamlined installations, potentially reducing the need for extensive conduit systems. Real-world experience attests to the importance of considering both the immediate requirements and the long-term implications when selecting conduit sizes. Engineers and contractors who balance these factors benefit from installations that not only meet current needs but are also poised for future upgrades. In conclusion, the process of selecting the appropriate corrugated conduit size is multifaceted, requiring a balance of technical understanding, practical foresight, and adherence to regulatory standards. By thoroughly evaluating these elements, professionals can ensure that their conduit systems are both efficient and compliant. Emphasizing quality and strategic planning in the selection process adds a layer of trustworthiness and credibility to each project, ultimately contributing to safer and more reliable installations.