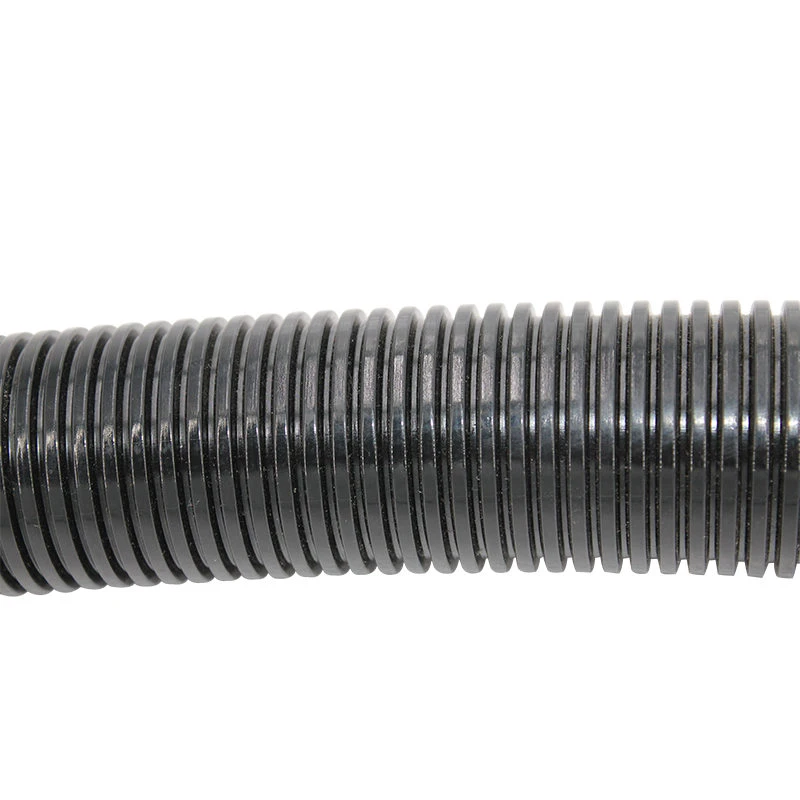

corrugated conduit

Corrugated conduit pipes are an essential component in various industries, offering exceptional flexibility, durability, and protection. These pipes are integral in safeguarding electrical wiring systems, enhancing water drainage solutions, and more. Their distinct design allows them to endure challenging environments while maintaining superior performance. This article delves into the world of corrugated conduit pipes by sharing expert insights, real-world applications, and guidelines for selecting the best options based on authoritative knowledge.

Trustworthiness comes into play when choosing a supplier. Users of corrugated conduit pipes should look for manufacturers with a proven track record and industry certifications. Case studies indicate that investing in high-quality pipes from reputable sources can prevent failures, reducing liabilities and protecting infrastructures. One should check for reviews and seek referrals from seasoned professionals who have encountered different scenarios where these pipes have reliably performed. The adaptability of corrugated conduit pipes extends to diverse applications. For example, in agriculture, they efficiently channel water and protect irrigation systems. Their lightweight nature simplifies installation, translating to cost savings and expediting project timelines. Electrical contractors favor them for their ability to accommodate difficult angles and compress into tight spaces without compromising the wiring integrity. Selecting the appropriate corrugated conduit pipe hinges on clearly understanding the specific needs of a given project. Issues such as load capacity, environmental conditions, and future expansion possibilities must be carefully analyzed. Consulting with industry experts and engaging with manufacturers can provide guidance in navigating these choices, ensuring that investments cater to immediate requirements while accommodating future changes. In conclusion, corrugated conduit pipes epitomize a blend of engineering excellence, practical application, and strategic foresight. They are a testament to innovation fitted to modern infrastructural demands. Leveraging experience and expertise from industry leaders can maximize their utility, offering protection and reliability across applications. The decision to utilize these pipes should be informed by diligent research, authoritative guidance, and trust in quality production practices, ultimately ensuring systems' seamless operation and longevity.

Trustworthiness comes into play when choosing a supplier. Users of corrugated conduit pipes should look for manufacturers with a proven track record and industry certifications. Case studies indicate that investing in high-quality pipes from reputable sources can prevent failures, reducing liabilities and protecting infrastructures. One should check for reviews and seek referrals from seasoned professionals who have encountered different scenarios where these pipes have reliably performed. The adaptability of corrugated conduit pipes extends to diverse applications. For example, in agriculture, they efficiently channel water and protect irrigation systems. Their lightweight nature simplifies installation, translating to cost savings and expediting project timelines. Electrical contractors favor them for their ability to accommodate difficult angles and compress into tight spaces without compromising the wiring integrity. Selecting the appropriate corrugated conduit pipe hinges on clearly understanding the specific needs of a given project. Issues such as load capacity, environmental conditions, and future expansion possibilities must be carefully analyzed. Consulting with industry experts and engaging with manufacturers can provide guidance in navigating these choices, ensuring that investments cater to immediate requirements while accommodating future changes. In conclusion, corrugated conduit pipes epitomize a blend of engineering excellence, practical application, and strategic foresight. They are a testament to innovation fitted to modern infrastructural demands. Leveraging experience and expertise from industry leaders can maximize their utility, offering protection and reliability across applications. The decision to utilize these pipes should be informed by diligent research, authoritative guidance, and trust in quality production practices, ultimately ensuring systems' seamless operation and longevity.