Twisted Split Loom Tubing for Enhanced Cable Management Solutions

Understanding Convoluted Split Loom Tubing Benefits and Applications

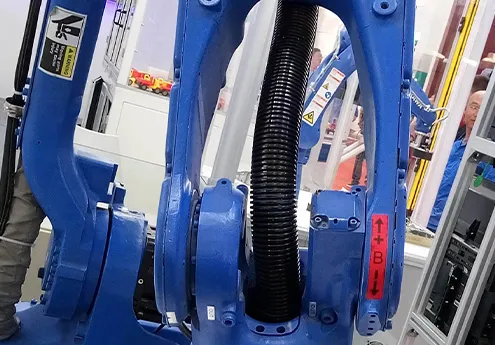

Convoluted split loom tubing, often referred to simply as split loom, is a vital component in the field of wire and cable protection. This highly versatile tubing is known for its unique design, characterized by a spiral structure that enables it to effectively manage and safeguard wiring in a multitude of environments. This article aims to explore the benefits and applications of convoluted split loom tubing while highlighting its importance in various industries.

At the core of its design, convoluted split loom tubing is engineered to provide outstanding protection against abrasion, environmental hazards, and various physical impacts. The convoluted structure creates a robust layer of defense for cables, shielding them from wear and tear in demanding settings. Given that wires are often subjected to friction or exposure to moisture, using split loom tubing is imperative for ensuring the longevity and reliability of electrical systems.

One of the most significant advantages of convoluted split loom tubing is its flexibility. Unlike rigid tubing, this convoluted design allows for easy installation in tight spaces or around corners. As a result, it is commonly used in automotive, aerospace, and industrial applications where space constraints often pose challenges. Moreover, its ability to accommodate a wide range of wire sizes makes it suitable for various projects, from home DIY tasks to professional installations.

In addition to flexibility, convoluted split loom tubing is made from durable materials that are resistant to chemicals, oils, and heat

. This resilience ensures that it can withstand the rigors of indoor and outdoor environments alike. For example, in automotive applications, it protects wiring harnesses from exposure to the harsh conditions found under the hood, including high temperatures and potential chemical spills. Similarly, in industrial settings, it serves as a safeguard for cables that may come in contact with machinery or sharp edges.convoluted split loom tubing

Another notable feature of convoluted split loom tubing is its ability to organize wiring effectively. By grouping cables together, it not only promotes a cleaner appearance but also simplifies maintenance and troubleshooting processes. The clear separation of wires reduces the risk of electromagnetic interference, enhancing the overall performance of electrical systems.

When it comes to installation, convoluted split loom tubing is incredibly user-friendly. The split design allows for quick insertion of cables without the need for additional tools or extensive disassembly of existing wiring systems. This ease of use translates to time and cost savings, making it advantageous for both individual users and large-scale manufacturers.

Convoluted split loom tubing is also eco-friendly, as many manufacturers produce it from recyclable materials. As awareness regarding environmental sustainability grows, having an option that minimizes the ecological footprint is an essential consideration for businesses and consumers alike.

In summary, convoluted split loom tubing is an indispensable element in the protection and management of wiring across diverse industries. Its unique design, flexibility, and resilience make it a reliable choice for safeguarding cables from various forms of damage. From automotive to industrial and beyond, the applications of this tubing are extensive and continue to grow as technology advances. Whether you’re an individual tackling a home improvement project or a professional in need of efficient wire management, convoluted split loom tubing offers unparalleled benefits that enhance both functionality and safety.