Complex Split Loom Tubing for Enhanced Cable Management Solutions

Understanding Convoluted Split Loom Tubing A Practical Guide

In the world of industrial and automotive applications, protecting wiring and cables is essential for longevity and functionality. Among the various solutions available, convoluted split loom tubing has emerged as a popular choice due to its unique properties and versatility. This article delves into what convoluted split loom tubing is, its benefits, applications, and installation practices.

What is Convoluted Split Loom Tubing?

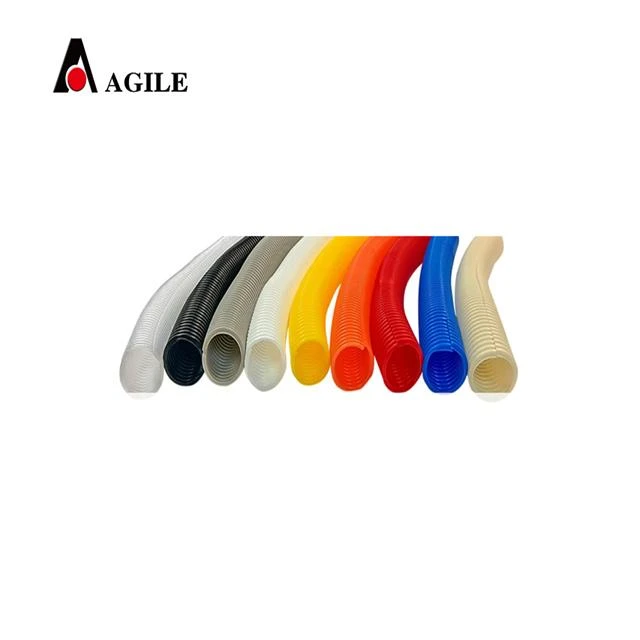

Convoluted split loom tubing is a type of flexible protective covering designed for wiring, cables, and hoses. The convoluted aspect refers to its ribbed design, which allows it to bend and flex while maintaining a degree of rigidity. The split feature means that the tubing is not a complete, closed tube—it has a slit along its length, enabling easy insertion and removal of cables without needing to disconnect them.

Made from durable materials like polyethylene or polypropylene, this tubing comes in various sizes and lengths, allowing it to accommodate different cable diameters and application needs.

Advantages of Convoluted Split Loom Tubing

1. Flexibility and Durability The unique design of convoluted split loom tubing allows it to adapt to various environments, making it suitable for use in automotive, aerospace, and industrial applications. Its flexible nature means it can curve around corners without compromising protection.

2. Easy Installation The split design enables users to quickly and easily insert wires and cables without the need for specialized tools. This feature is especially valuable in applications where cables need to be added or removed frequently.

3. Protection Against External Factors The tubing provides excellent protection against abrasion, moisture, chemicals, and extreme temperatures. This resilience extends the lifespan of the cables housed within, reducing maintenance costs and downtime.

4. Organizational Benefits By grouping multiple cables into a single protective tube, convoluted split loom tubing helps keep wiring organized and tidy. This not only improves the visual appearance of a workspace but also simplifies troubleshooting and repairs.

5. Cost-Effectiveness It acts as a protective barrier, decreasing the likelihood of damage to cables, which can be costly to repair or replace. By using this tubing, businesses can save money on maintenance and prolong the life of their wiring systems.

convoluted split loom tubing

Applications of Convoluted Split Loom Tubing

Convoluted split loom tubing is widely used across various industries, including

- Automotive From cars to trucks, this tubing protects wiring that could be exposed to moisture, heat, and friction, ensuring reliable performance. - Aerospace In this high-stakes industry, protecting electrical systems is critical. The tubing’s resistance to harsh environments makes it an ideal candidate for aircraft applications. - Industrial Machinery Heavy equipment and machinery often involve complex wiring systems. Convoluted split loom tubing keeps cables secure and protected from mechanical wear. - Consumer Electronics In electronic devices, protecting internal wiring is crucial for safety and performance. This tubing helps maintain that integrity while offering aesthetic advantages.

Installation Tips

When installing convoluted split loom tubing, consider the following tips

1. Choose the Right Size Ensure that the diameter of the tubing appropriately fits the cables you intend to protect. This can provide optimal protection while preventing excessive bulk. 2. Prepare the Cables Before installation, clean the cables to eliminate any dirt or debris. This not only facilitates smoother insertion but also helps maintain the integrity of the cables.

3. Cut to Length Measure and cut the tubing to the desired length. It’s better to start slightly longer and trim it down if necessary.

4. Insert the Cables Open the split along the length of the tubing and insert your cables, ensuring they fit snugly within the protective casing.

5. Secure as Needed Depending on the application and environment, you may want to use additional methods—like zip ties or clamps—to ensure the tubing stays in place.

Conclusion

In summary, convoluted split loom tubing stands as a reliable solution for protecting cables across various industries. Its flexibility, durability, ease of installation, and cost-effectiveness make it an invaluable asset for professionals dealing with complex wiring systems. By understanding its benefits and applications, users can maximize the efficiency and safety of their electrical systems. Whether in automotive, aerospace, or industrial settings, convoluted split loom tubing proves its worth as a fundamental component in cable management.