conduit corrugated

The Significance of Conduit Corrugated Materials in Modern Infrastructure

In the realm of construction and infrastructure, the choice of materials plays a critical role in determining the longevity, efficiency, and safety of various installations. Among the numerous options available, corrugated conduits have emerged as a favored solution for managing electrical wiring and other utilities. This article explores the significance of conduit corrugated materials, their benefits, applications, and the reasons behind their growing popularity in modern infrastructure projects.

Understanding Corrugated Conduits

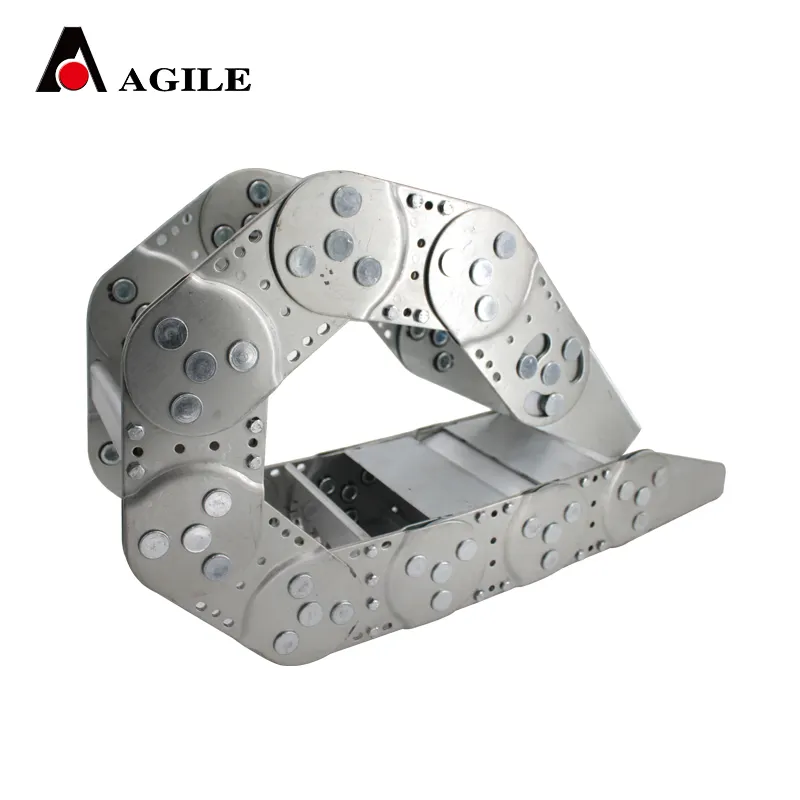

Corrugated conduits are cylindrical tubes made from durable materials such as plastic or metal, characterized by a series of ridges and grooves along their surface. This unique design not only enhances flexibility but also provides strength and durability. The corrugated structure allows the conduit to bend and curve around obstacles without compromising its integrity. These conduits are primarily used to protect electrical wires and cables, ensuring they remain safe from environmental factors, physical impact, and other potential hazards.

Benefits of Corrugated Conduits

1. Flexibility and Versatility One of the primary benefits of corrugated conduits is their flexibility. Unlike rigid conduits, which may require multiple fittings and connectors, corrugated conduits can easily navigate around obstacles and tight corners. This versatility makes them ideal for various applications, including residential, commercial, and industrial settings.

2. Enhanced Protection Corrugated conduits provide exceptional protection for electrical wiring. The robust nature of these materials shields cables from moisture, chemicals, and physical damage. This protective capability is especially crucial in environments where wires are exposed to harsh conditions, such as in underground installations or industrial facilities.

conduit corrugated

3. Lightweight and Cost-Effective The materials used in corrugated conduits are often lightweight, making them easier to handle and install. This ease of installation can significantly reduce labor costs, which is a critical consideration in large-scale projects. Furthermore, the durability of these conduits leads to lower maintenance costs over time, contributing to their cost-effectiveness.

4. Improved Aesthetics In many installations, especially in residential and commercial buildings, the visual impact of visible conduits can be a concern. Corrugated conduits can be easily concealed or integrated into building designs, providing an aesthetically pleasing solution for electrical management.

Applications in Modern Infrastructure

Corrugated conduits are utilized in various applications across multiple industries. In residential construction, they are commonly used to house electrical wires for lighting and appliances. In commercial buildings, they protect wiring for HVAC systems, security systems, and telecommunications. Furthermore, in industrial settings, corrugated conduits are critical for safeguarding high-voltage cables and sensitive equipment from the rigors of the manufacturing environment.

Moreover, with the increasing emphasis on green building practices, corrugated conduits made from recycled materials have started to gain traction. These eco-friendly options align with sustainability goals while maintaining the same quality and performance standards as traditional conduits.

Conclusion

In conclusion, conduit corrugated materials have become an integral component in modern infrastructure due to their unique combination of flexibility, durability, and cost-effectiveness. As industries continue to evolve and adapt to new technologies and sustainability practices, the demand for reliable and efficient solutions like corrugated conduits will only grow. Their ability to protect essential electrical systems while offering ease of installation and aesthetic appeal makes them a preferred choice for architects, engineers, and builders alike. As we look toward the future, the importance of such materials will undoubtedly continue to rise, shaping the way we approach construction and infrastructure development.