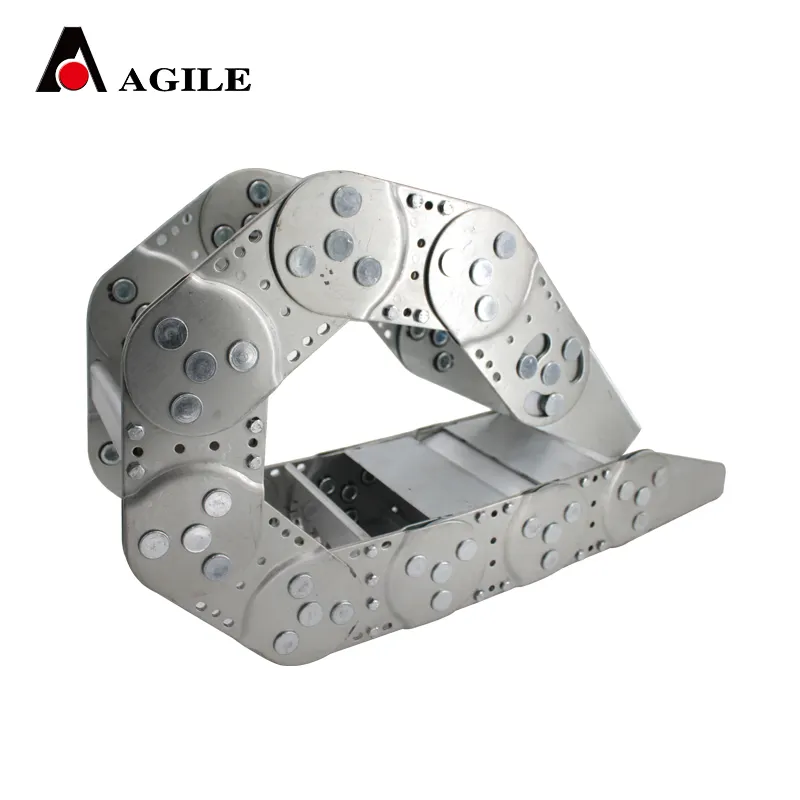

cnc wire track

Understanding CNC Wire Track A Key Component in Modern Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) technology has transformed the way products are designed and fabricated. Among its many components, the CNC wire track plays a crucial role in ensuring the precision and efficiency of machining processes. This article delves into the significance of CNC wire tracks, their functionality, and their applications in various industries.

What is CNC Wire Track?

CNC wire track refers to the system that guides the movement of the wire used in wire cut electrical discharge machining (EDM). In this process, a thin wire, typically made of brass or copper, is used to cut complex shapes and contours in metal workpieces. The CNC wire track ensures that the wire remains properly aligned and tensioned throughout the cutting process, contributing to the accuracy and quality of the final product.

How Does CNC Wire Track Work?

The CNC wire track operates through a series of pulleys, guides, and tensioning mechanisms that keep the wire in place. When a CNC machine is programmed to perform a specific cut, the wire is fed through the workpiece with precision. The wire track maintains the correct position of the wire, preventing deviations that could lead to defects. Additionally, the tensioning system helps to ensure that the wire remains taut, which is vital for achieving clean, precise cuts.

Benefits of Using CNC Wire Track

1. Precision and Accuracy One of the primary advantages of CNC wire tracks is their ability to maintain consistent wire tension and alignment, which is essential for producing accurate cuts. This precision is crucial in industries where tolerances are tight, such as aerospace, automotive, and medical device manufacturing.

cnc wire track

2. Increased Efficiency CNC wire tracks contribute to the overall efficiency of the machining process. By ensuring that the wire is fed and maintained correctly, machines can operate at higher speeds without sacrificing quality. This translates to shorter production times and, ultimately, cost savings.

3. Reduced Wear and Tear A well-designed wire track minimizes friction and wear on the wire, extending its lifespan and reducing the frequency of replacements. This aspect is particularly beneficial in high-volume production environments, where minimizing downtime is critical.

4. Versatility CNC wire tracks can accommodate various wire types and diameters, making them highly versatile for different machining applications. This adaptability allows manufacturers to use a single setup for multiple projects, streamlining their operations.

Applications of CNC Wire Track

CNC wire tracks are employed across a wide range of industries, including

- Automotive Used for cutting intricate components, such as gears and tools, that require high precision. - Aerospace Essential for manufacturing parts that adhere to strict safety and performance standards. - Medical Devices In the production of surgical instruments and implants, where precision is paramount. - Tool and Die Making CNC wire tracks are invaluable in creating molds and dies that require exact specifications.

Conclusion

CNC wire tracks are an integral part of contemporary machining processes, providing the precision and efficiency necessary for competitive manufacturing. As industries continue to evolve and demand higher quality outputs, the role of CNC wire tracks is likely to become more pronounced. Investing in advanced wire track systems can greatly enhance production capabilities, enabling manufacturers to meet the growing needs of their respective markets. As technology advances, we can expect further innovations in CNC wire track design and functionality, paving the way for even more sophisticated manufacturing solutions.