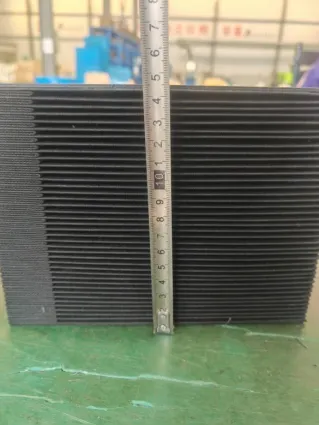

cnc wire track

CNC Wire Track Revolutionizing Precision Machining

In the realm of modern manufacturing, the advent of CNC (Computer Numerical Control) technology has marked a significant turning point in precision machining. Among the various innovations introduced by CNC technology, the CNC wire track stands out as a crucial component that enhances efficiency and accuracy in multiple industries, especially in metalworking and fabrication.

What is CNC Wire Track?

CNC wire track refers to a sophisticated guide system used to facilitate the movement of wires in CNC machines. Typically integrated within wire EDM (Electrical Discharge Machining) machines, these tracks ensure that feeding wires are consistently positioned for precise cutting operations. The primary function of a wire track is to maintain the optimal alignment of wires, preventing tangles and ensuring uninterrupted machining processes.

The Mechanism Behind CNC Wire Tracks

The operation of CNC wire tracks is predicated on a well-designed guiding system that can accommodate the complexities of wire movement. Wire tracks typically feature a low-friction surface, allowing wires to glide smoothly as they are fed into the machining area. The tracks are engineered to handle variations in wire diameter and material, which is essential for maintaining precision during the cutting process.

The tracks are often adjustable, allowing operators to modify the setup based on the specific requirements of the job at hand. By allowing for precise positioning, CNC wire tracks minimize lateral movement, which can lead to inaccuracies in cutting and increased wear on the machinery.

Benefits of Utilizing CNC Wire Tracks

cnc wire track

1. Enhanced Precision The primary advantage of employing CNC wire tracks is the significant increase in cutting precision. With the wires guided properly throughout the machining process, manufacturers can achieve tighter tolerances that are critical in industries such as aerospace and automotive manufacturing.

2. Increased Efficiency CNC wire tracks improve the overall efficiency of the machining process. By ensuring a consistent feed and reducing manual adjustments, operators can save valuable time, allowing for higher throughput and decreased production costs.

3. Reduced Downtime With less chance of wire tangling or misalignment, CNC wire tracks contribute to reduced machine downtime. Downtime can be costly in any manufacturing operation; thus, optimizing the performance of wire EDM machines through reliable wire tracks is essential.

4. Flexibility in Applications CNC wire tracks are versatile and can accommodate various materials and cutting requirements. Whether working with titanium, stainless steel, or other metals, the adaptability of these tracks makes them suitable for diverse industrial applications.

5. Improved Safety Proper wire management through effective tracks decreases the risk of accidents and injuries associated with tangling wires or machinery jams. This contributes to a safer working environment, which is a priority in any manufacturing facility.

Conclusion

The CNC wire track serves as a fundamental element in the evolution of precision machining. As industries continue to demand higher levels of accuracy and efficiency, the reliance on sophisticated tooling and guidance systems like CNC wire tracks will only increase. As advancements in technology continue, we can expect further innovations in wire management solutions that will drive the future of manufacturing toward greater productivity and excellence.

In summary, CNC wire tracks play a pivotal role in ensuring the efficiency and precision of wire EDM processes, rendering them indispensable in the modern manufacturing landscape. As the industry evolves, the importance of these components will only grow, reinforcing their status as a cornerstone of precision engineering. With a commitment to continuous improvement and adaptation, the world of CNC machining stands poised to embrace a future defined by accuracy, speed, and innovation.