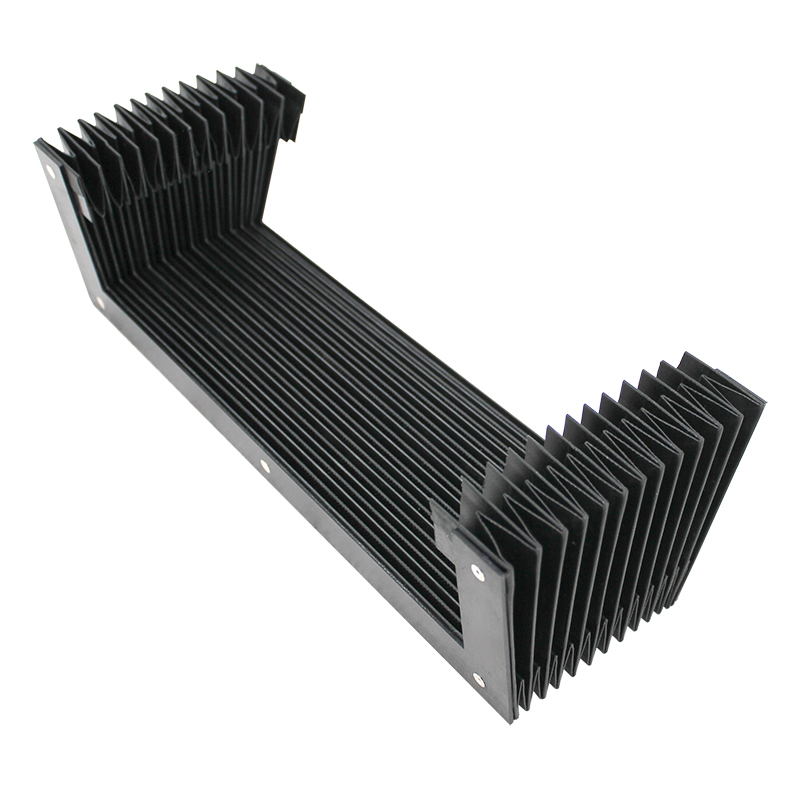

cnc wire track

Understanding CNC Wire Track Innovations and Applications

Computer Numerical Control (CNC) technology has transformed the manufacturing landscape over the last few decades, streamlining procedures and enhancing precision. One of the critical elements in this revolution is the CNC wire track. This innovative system plays an essential role in wire processing—particularly in industries such as electronics, automotive, and aerospace—where accuracy and reliability are paramount.

At its core, a CNC wire track is designed to guide and manage the path of the wire during machining processes. It is an integral part of CNC wire cutting machines, where high-precision cutting is required. The wire, often made from materials like copper or steel, is fed through a series of tracks that help maintain its position while being cut, shaped, or manipulated. This meticulous handling ensures superior control and outcomes in the fabrication of intricate parts.

Understanding CNC Wire Track Innovations and Applications

In addition to versatility, the CNC wire track contributes to the overall precision of the machining process. By ensuring that the wire remains stable and accurately positioned, manufacturers can achieve tighter tolerances and superior surface finishes. This precision is essential in high-stakes industries where even minor errors can lead to costly defects. Consequently, investing in advanced CNC wire tracks can significantly enhance quality control processes and reduce scrap rates.

cnc wire track

Furthermore, the CNC wire track system is designed for automation, aligning perfectly with the trends toward smart manufacturing. Many modern CNC machines come equipped with advanced software that allows for real-time monitoring of the wire’s position and condition. This capability not only improves operational efficiency but also reduces the need for manual intervention, thereby minimizing the risk of human error. Automation through CNC wire tracks can significantly speed up production cycles and lower labor costs.

However, the implementation of CNC wire tracks is not without challenges. The initial investment in advanced machinery and software can be substantial, and training personnel to operate these systems effectively requires time and resources. Additionally, the maintenance of these sophisticated systems is crucial; any malfunction can halt production and lead to costly downtime. Therefore, it’s essential for manufacturers to consider their long-term strategies and operational needs before integrating CNC wire technology into their workflow.

Despite these challenges, the future of CNC wire tracks looks promising. As technology evolves, we can expect further innovations that enhance the capabilities and efficiency of these systems. Developments in materials science could lead to even more durable and lightweight wire tracks, while advancements in artificial intelligence and machine learning may enable smarter prediction and adjustment measures during the manufacturing process.

In conclusion, CNC wire tracks are pivotal to modern manufacturing, offering unmatched precision, versatility, and automation potential. As industries continue to embrace these technologies, manufacturers who invest in CNC wire cutting systems will likely reap significant rewards in terms of efficiency and output quality. The evolution of this technology not only reflects the advancements in machinery but also showcases the industry’s ongoing commitment to innovation and excellence in manufacturing practices. As we look ahead, the integration of CNC wire tracks will continue to shape the future of manufacturing, driving advancements across a multitude of sectors.