CNC Milling Machine Chip Removal System and Conveyor Solutions

The Importance of Chip Conveyors in CNC Milling Operations

In the world of CNC (Computer Numerical Control) milling, efficiency and precision are paramount. As manufacturers strive to improve productivity and ensure high-quality output, one critical component often overlooked is the chip conveyor. This seemingly simple system plays a vital role in optimizing milling operations, reducing downtime, and enhancing overall machine performance.

What is a Chip Conveyor?

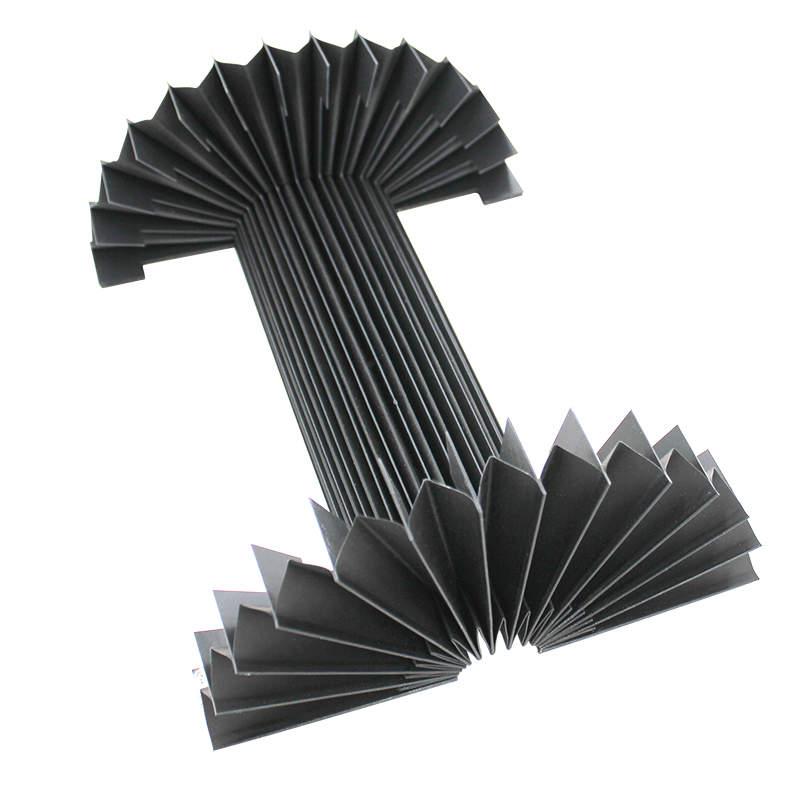

A chip conveyor is a mechanical device designed to transport metal chips, shavings, and other debris generated during the CNC milling process away from the machine tool. These chips can be produced from various materials, including aluminum, steel, and plastic, depending on the workpiece being machined. The type of conveyor used may vary, including bucket, screw, magnetic, or belt conveyors, each tailored to handle specific materials and chip types.

Why Chip Conveyors Matter

1. Efficiency and Productivity The continuous removal of chips from the machining area is essential. When chips accumulate, they can obstruct the machining process, leading to slower operation and increased cycle times. By employing a chip conveyor, manufacturers can maintain a clean working environment, allowing CNC machines to operate at optimal speeds without interruptions.

2. Enhanced Machining Accuracy An orderly work environment enables better visibility and access to the milled part, resulting in greater control over machining operations. Chips left in the milling area can affect tool engagement and positioning, which may lead to misalignments and errors. A chip conveyor helps ensure that tools produce precise cuts consistently by keeping the area clear.

cnc mill chip conveyor

3. Reducing Wear and Tear on Machinery Chips can be abrasive and potentially damaging to equipment if not properly managed. They can lead to increased wear on cutting tools and machine components. By effectively removing these chips through a conveyor system, manufacturers can prolong the life of their tools and machinery, resulting in lower maintenance costs and reduced downtime for repairs.

4. Improved Safety Accumulated chips and debris create hazardous working conditions. Workers may slip or trip over discarded chips, leading to injuries. Chip conveyors minimize these risks by keeping the work area clean and organized, thus enhancing workplace safety.

5. Environmental Considerations Efficiently managing chips also has environmental benefits. Many chip types can be recycled, and a chip conveyor allows for the easy collection and separation of different materials. This not only contributes to sustainability initiatives but can also reduce disposal costs for manufacturers.

Choosing the Right Chip Conveyor

When selecting a chip conveyor for CNC milling operations, several factors must be considered, including the type of material being machined, the volume of chips produced, the space available for installation, and the required transport distance. Each type of conveyor offers unique advantages and limitations, making it crucial to align the conveyor system with the specific needs of the machining operation.

Conclusion

In summary, chip conveyors are integral to the efficiency and effectiveness of CNC milling operations. They help maintain clean working environments, enhance machining accuracy, reduce wear on machinery, improve workplace safety, and support environmental sustainability. As manufacturers continue to seek ways to optimize their operations, investing in the right chip conveyor system can yield significant returns in productivity and cost savings, ultimately leading to greater competitiveness in the ever-evolving manufacturing landscape.