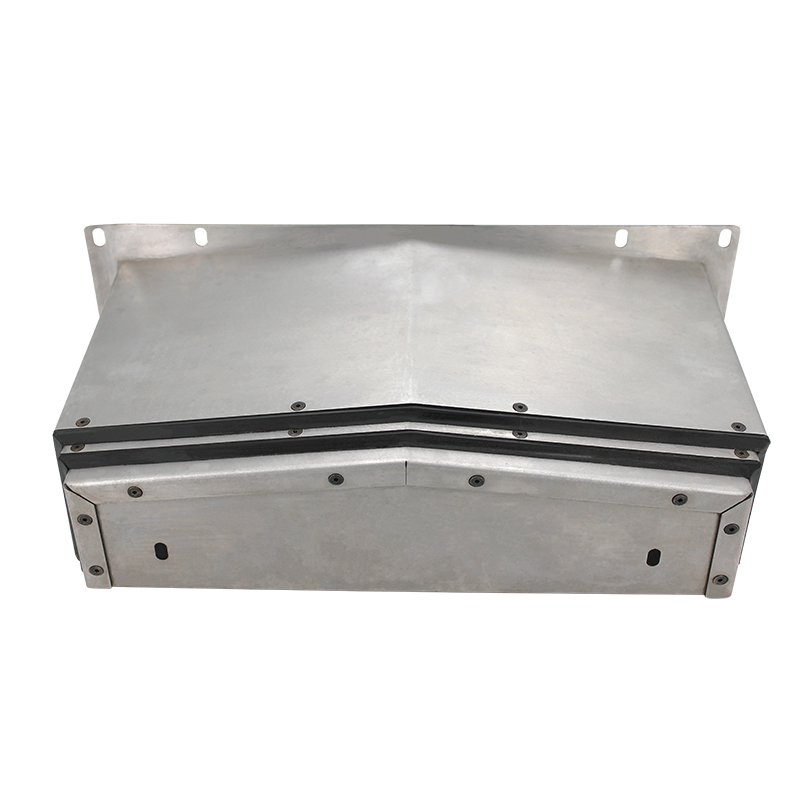

cnc lathe chip conveyor

CNC Lathe Chip Conveyor Maximizing Efficiency in Machining Processes

In the field of machining, particularly when it comes to CNC (Computer Numerical Control) lathes, the efficient handling of waste material such as metal chips is critical. As production rates increase, so does the volume of chips generated, necessitating an effective method for chip removal. This is where CNC lathe chip conveyors come into play, optimizing the machining process and ensuring a clean and safe working environment.

The Importance of Chip Management

During the CNC lathe operations, various materials such as aluminum, steel, and plastic are often machined, leading to the production of chips or shavings. If not managed properly, these chips can clog machines, impede workflow, and present safety hazards. Effective chip management is vital not only for maintaining machine efficiency but also for safeguarding employees from potential accidents caused by slippery floors or flying metal debris.

How CNC Lathe Chip Conveyors Work

CNC lathe chip conveyors are designed to remove these metal chips from the machining area and transport them to a designated disposal point. There are several types of conveyors, including

1. Auger Conveyors These use a rotating helical screw to move chips along a fixed channel. Auger conveyors are efficient for smaller chips and are often used in CNC operations where space is limited.

2. Drag Chain Conveyors These utilize a chain to drag a series of pallets or scrapers through a trough filled with chips. They are particularly effective for larger chips and can handle higher volumes compared to auger systems.

3. Belt Conveyors With a flat rubber or metal belt system, these conveyors are versatile and suitable for various chip sizes. They are easy to maintain and can be adapted to transport chips at different angles.

cnc lathe chip conveyor

5. Vacuum Conveyors Particularly suitable for smaller workshops, vacuum systems suction chips into a collection container, providing a clean and efficient solution that minimizes manual handling.

Benefits of Using Chip Conveyors

The integration of CNC lathe chip conveyors into machining operations offers several notable benefits

- Increased Productivity By automating the chip removal process, machine operators can focus on machining tasks without frequent interruptions for chip clearing. This leads to a significant increase in productivity and overall machine utilization.

- Enhanced Safety A clean workspace is paramount for safety. By effectively removing chips, conveyors reduce the risk of slips, trips, and falls, creating a safer environment for operators.

- Improved Equipment Longevity Regular and efficient chip removal helps maintain the cooling systems of the CNC lathe and prevents excessive wear and tear, ultimately extending the equipment's lifespan.

- Better Recycling and Waste Management Many CNC lathe chip conveyors are designed to facilitate the collection of chips for recycling. This environmentally friendly approach minimizes waste and can even generate revenue from recyclable materials.

- Cost Efficiency Although investing in chip conveyor systems involves initial costs, the long-term savings gained from increased efficiency, reduced downtime, and enhanced safety standards significantly outweigh these expenses.

Conclusion

In conclusion, CNC lathe chip conveyors play a crucial role in the machining industry. By automating the process of chip removal, they not only enhance productivity but also improve safety and contribute to effective waste management. As technology continues to evolve, the design and efficiency of chip conveyors will likely improve, making them an indispensable component of modern CNC machining operations. Investing in these systems is a step towards cultivating a more efficient, safe, and environmentally responsible machining workspace.