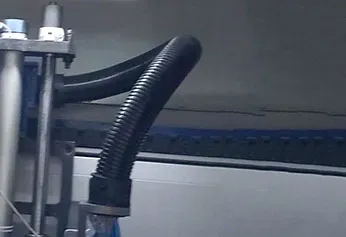

cnc lathe chip conveyor

The Importance of CNC Lathe Chip Conveyors in Modern Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machinery has revolutionized the way parts are produced. Among the myriad components that enhance the efficiency and productivity of CNC lathes, chip conveyors play a crucial role. These devices are not merely accessories; they are essential for maintaining workflow, ensuring safety, and prolonging the life of machining equipment.

The Role of CNC Lathes in Manufacturing

CNC lathes are designed to automate the turning process, allowing for high precision and complexity in the manufacturing of components. However, as these machines operate, they generate metal chips and shavings that, if not managed properly, can lead to significant operational challenges. These chips can accumulate quickly, obstructing the work area, interfering with machine operations, and posing safety hazards to operators.

What are Chip Conveyors?

Chip conveyors are specifically designed systems that remove these metal chips from the lathe area. They ensure that chips are effectively transported away from the machine, reducing the risk of clogs and the accumulation of debris. Chip conveyors come in various designs, including hinged steel belt conveyors, screw-type conveyors, and magnetic conveyors, each suited to different machining environments and materials.

Benefits of Chip Conveyors in CNC Lathes

1. Enhanced Workflow Efficiency One of the primary benefits of integrating chip conveyors with CNC lathes is the significant improvement in workflow efficiency. By automatically removing chips and shavings, these systems allow the machining process to continue uninterrupted. This reduces downtime, allowing manufacturers to maximize their operational throughput.

cnc lathe chip conveyor

2. Improved Workplace Safety The removal of metal chips also contributes to a safer working environment. Accumulated chips can lead to slips, trips, or falls, posing risks to operators. Additionally, they can hinder machine operation, leading to potential accidents. By effectively managing chip disposal, conveyors help maintain a cleaner and safer workspace.

3. Reduced Machine Wear and Tear Excessive chip accumulation can lead to overheating and increased wear on machine components. A chip conveyor helps to mitigate these risks by ensuring that chips are consistently cleared away from the lathe. This, in turn, extends the life of the machine and reduces maintenance costs.

4. Versatility in Chip Handling Different materials produce chips of various sizes and types. Chip conveyors can be customized to handle a wide range of materials, whether they are aluminum, steel, or other alloys. This versatility makes them an invaluable asset in multi-material manufacturing processes.

5. Cost-Effectiveness While there is an initial investment associated with chip conveyor systems, the long-term savings in labor costs and machine maintenance can be substantial. By automating the chip removal process, manufacturers can allocate human resources to more skilled tasks, improving overall productivity.

Choosing the Right Chip Conveyor

When selecting a chip conveyor for CNC lathes, manufacturers should consider several factors, such as the type of material being machined, the volume of chips produced, and the available space within the production area. The right chip conveyor should not only meet the operational needs but also integrate seamlessly with existing machinery.

Conclusion

In conclusion, CNC lathe chip conveyors are indispensable in the modern manufacturing landscape. They enhance efficiency, promote workplace safety, reduce machine wear, and can be customized to handle diverse machining processes. As manufacturers strive to improve productivity while ensuring safety, the role of chip conveyors will only continue to grow, solidifying their position as essential components in advanced manufacturing systems. Investing in a reliable chip conveyor is not just a matter of convenience but a strategic choice that can lead to substantial productivity gains and a safer working environment.